Detailed content

Technical Specifications

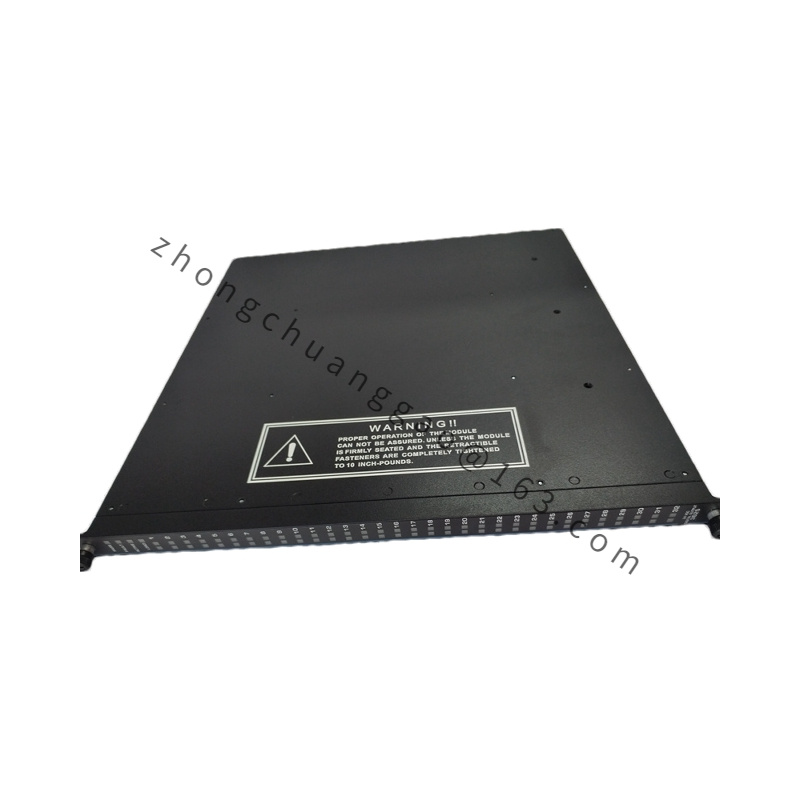

- Model: Triconex CIM3211S2

- Type: Communication Interface Module

- Manufacturer: Triconex (a division of Schneider Electric)

- Communication Protocols: Supports various communication protocols for interfacing with other systems and devices.

- Number of Ports: Typically equipped with multiple ports (e.g., RS-232, RS-485) for serial communication.

- Data Transmission Rate: Varies depending on the protocol and configuration.

- Power Supply: Operates on the power supplied by the Tricon system, typically 24V DC.

Functionality

- Communication Management: Handles communication between the Triconex control system and other external systems or devices, such as SCADA systems, PLCs, or field devices.

- Protocol Conversion: Facilitates the conversion between different communication protocols, enabling integration with a variety of third-party systems.

- Data Exchange: Enables reliable data exchange and integration across different parts of the control system and external systems.

- Error Handling: Includes features for detecting and managing communication errors to maintain system reliability.

Features

- Redundancy: Supports redundant configurations to enhance system reliability and availability.

- Diagnostics: Provides diagnostic capabilities to monitor communication health and troubleshoot issues.

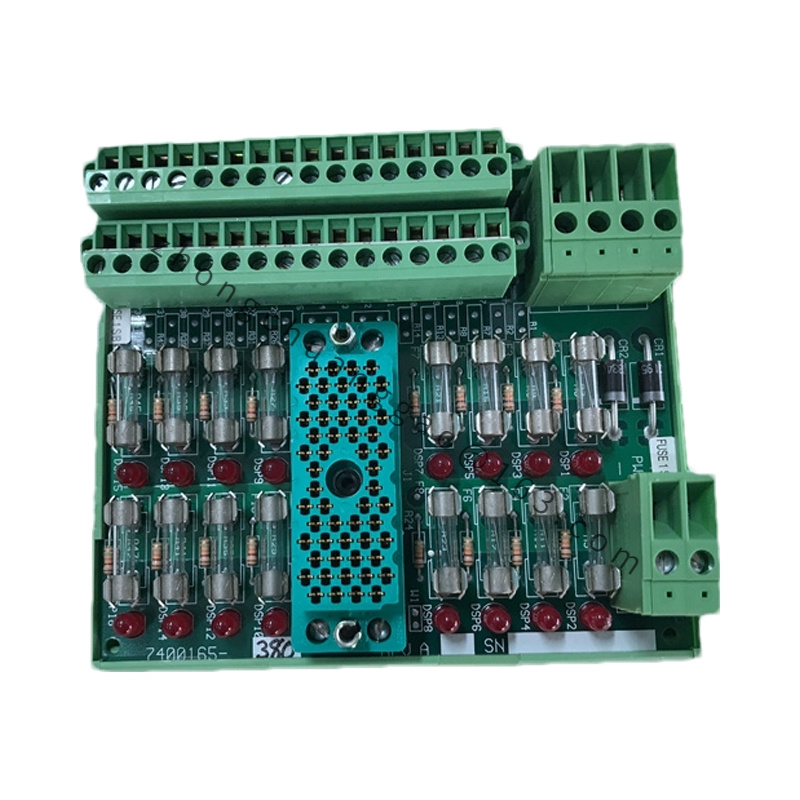

- Modular Design: Part of the modular Triconex system, which allows for flexible configuration and expansion.

- Hot Swap: Some configurations allow for hot swapping, which means the module can be replaced without shutting down the system.

Application Scenarios

- Industrial Automation: Used in industrial automation systems for connecting the Triconex control system to various automation devices and systems.

- Process Control: Facilitates communication between the Triconex system and process control devices, such as sensors and actuators.

- Safety Systems: Integral in safety-critical applications where communication between different safety systems and devices is crucial.

- SCADA Integration: Connects the Triconex system with SCADA systems for supervisory control and data acquisition.

Compatibility

- Control System: Specifically designed for use with the Triconex Tricon control system, ensuring compatibility and optimal performance.

Installation and Maintenance

- Mounting: Typically installed in a control panel or rack alongside other Triconex modules.

- Configuration: Requires configuration to match the communication protocols and settings of the connected systems.

- Maintenance: Regular monitoring and diagnostics are recommended to ensure continuous communication and system performance.