Detailed content

Technical Specifications

| Specification | Description |

|---|---|

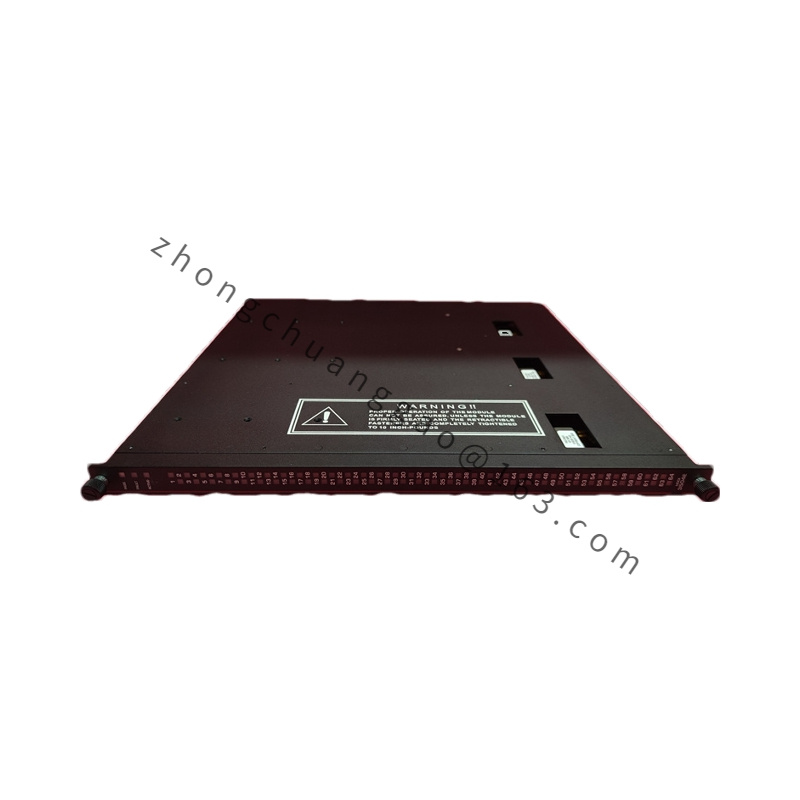

| Model | 9761-210 |

| Manufacturer | Invensys/Congsen |

| Application | DCS distributed control systems and PLC programming controllers |

| Communication Protocols | TriStation, Modbus, TCP/IP, and others for flexible integration |

| Voting Mechanism | Two-out-of-three (2oo3) voting for high integrity and fault tolerance |

| Power Supply | Dual power redundancy, DC (9-36)V, typical DC24V, < 4W, with DC1500V voltage isolation and reverse polarity protection |

| Relay Alarm Output | For fiber link and power failure, DC48V/1A, industrial terminal interface |

| Dimensions | 132mm x 105mm x 52mm |

| IP Rating | IP30 for protection against environmental hazards |

| Mounting Method | 35mm DIN rail mounting |

| Operating Temperature | -10°C to 70°C (-40°C to +85°C wide range optional) |

| Relative Humidity | ≤90% (non-condensing) |

| Storage Temperature | -40°C to 80°C |

| Test and Certification | Compliant with EN55022, EN61000-4 series, and other international standards |

Functional Characteristics

- High Integrity and Fault Tolerance: The 9761-210 utilizes a two-out-of-three (2oo3) voting mechanism, ensuring that the system operates with high integrity and minimal errors. This mechanism ensures that even in the event of a single channel failure, the system can continue to operate seamlessly.

- Triple Modular Redundancy (TMR): The module incorporates TMR architecture, providing three isolated parallel control systems for enhanced reliability and fault tolerance. Each channel independently executes control programs in parallel with the other two channels.

- Extensive Diagnostic Capabilities: The module has built-in diagnostic features that can detect and report operational faults through indicators or alarms. This simplifies fault identification and repair processes.

- Flexible Communication: With support for multiple communication protocols, the 9761-210 can seamlessly integrate with various industrial automation systems, enabling data exchange and communication.

- Easy Maintenance: Faulty modules can be easily replaced during system operation, minimizing downtime and maximizing system availability.

Application Scenarios

The Triconex 9761-210 is widely used in various industries that require high levels of reliability and safety, including:

- Power Generation: For controlling critical equipment in power plants, ensuring stable and efficient power generation.

- Oil and Gas: In refining, extraction, and transportation processes, where safety and reliability are paramount.

- Chemical and Petrochemical: For controlling complex processes in chemical plants and refineries.

- Metallurgy: In steel and metal production, for managing furnaces, melting equipment, and other critical machinery.

- Paper and Pulp: For controlling paper manufacturing processes, ensuring consistent quality and efficiency.