Detailed content

Technical Specifications

- Type:

- Category: Safety PLC (Programmable Logic Controller)

- Functionality:

- Type: The Triconex 9566 is a safety-related input/output (I/O) module designed for use in Tricon safety systems.

- Channels: Typically designed for handling multiple I/O channels for high-reliability safety functions.

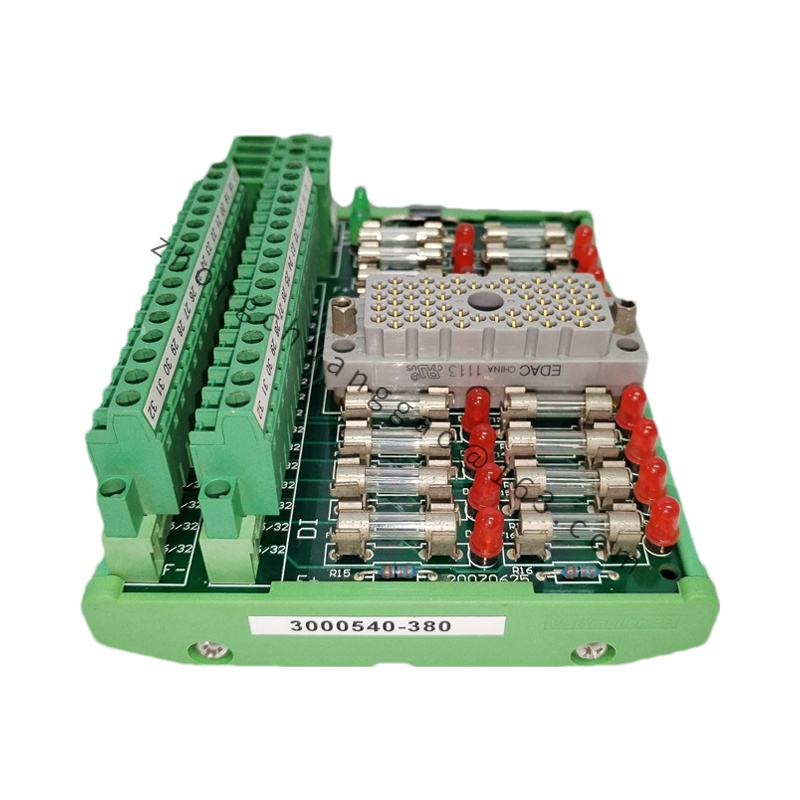

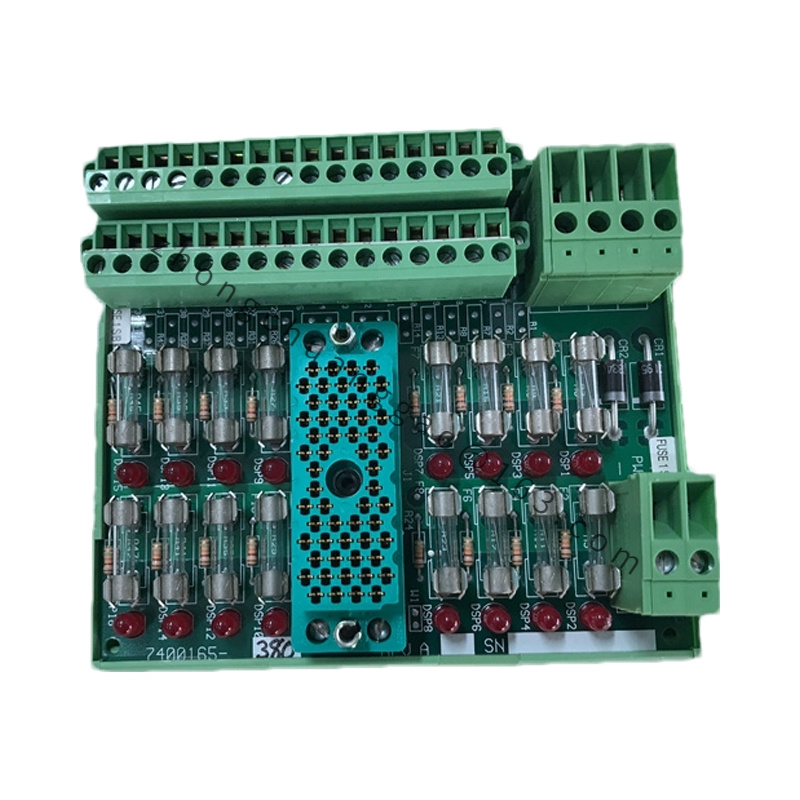

- I/O Configuration:

- Inputs: Usually supports digital or analog inputs depending on configuration. The specific number of inputs and type (e.g., 8 or 16 digital inputs) should be verified in the datasheet.

- Outputs: Typically includes digital outputs that interface with external devices, such as relays or actuators.

- Communication:

- Interface: Connects with Tricon systems using proprietary communication protocols. Ensures reliable data exchange between the PLC and the I/O modules.

- Performance:

- Response Time: Designed to meet stringent requirements for response times and reliability in safety applications.

- Safety Integrity Level (SIL): Compliant with specific SIL standards, such as SIL 3, to ensure high levels of safety and reliability.

- Power Supply:

- Voltage: Operates on a specified DC voltage, commonly in the range of 24V DC, but exact specifications should be confirmed.

- Temperature and Environmental Conditions:

- Operating Temperature: Typically from -20°C to +60°C (-4°F to +140°F).

- Humidity: Can operate in environments with up to 90% relative humidity (non-condensing).

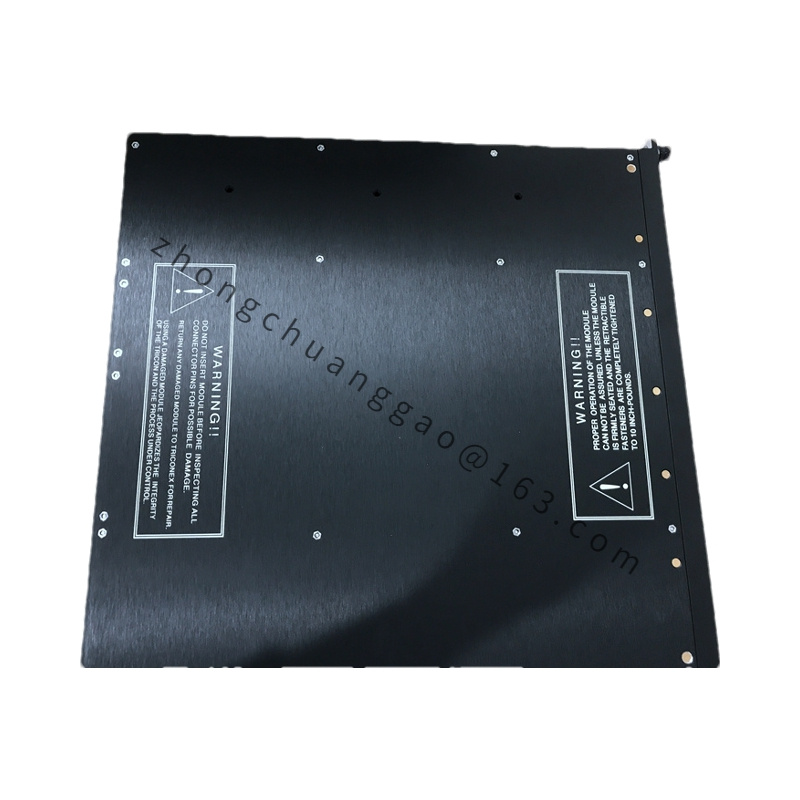

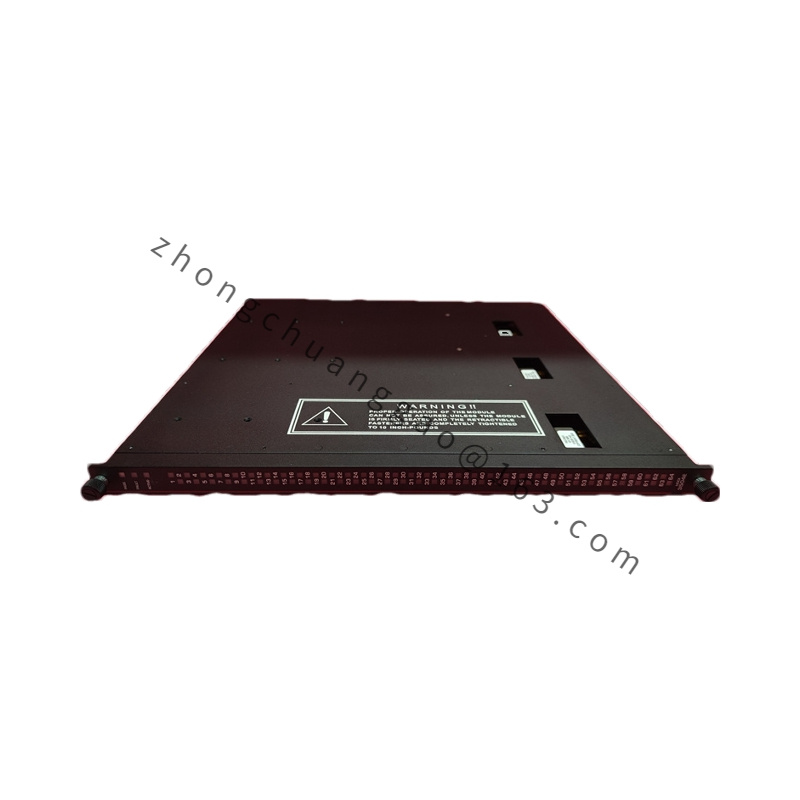

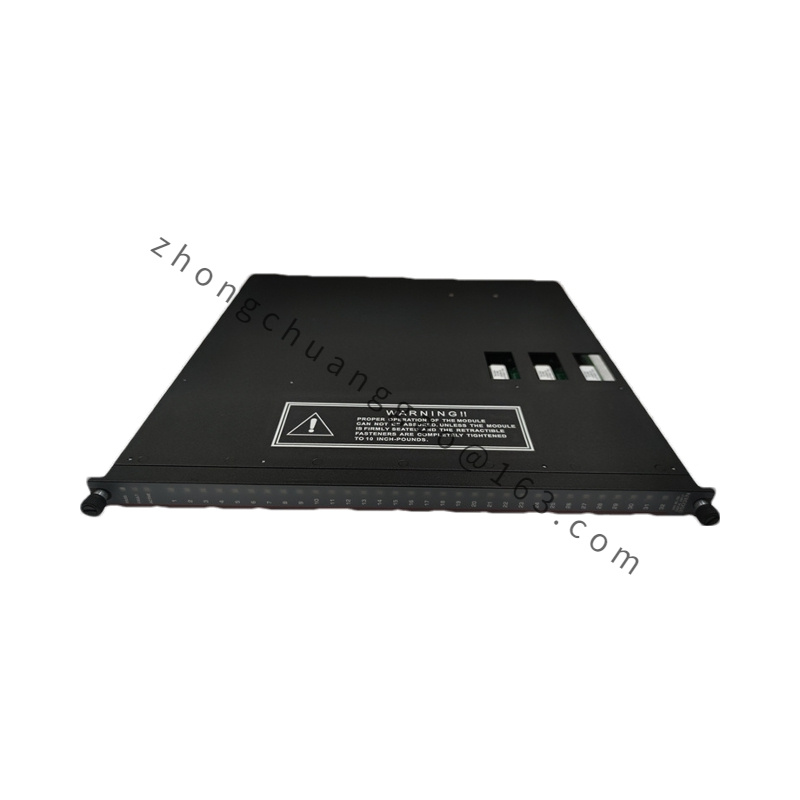

- Physical Dimensions:

- Size: Compact and designed to fit within standard Triconex racks or enclosures.

- Mounting: Typically mounted on a DIN rail or similar rack system.

Functional Features

- High Reliability:

- Redundancy: Includes redundancy features to ensure continuous operation in the event of hardware failure.

- Diagnostics: Advanced diagnostic capabilities to detect and report faults or performance issues.

- Safety Compliance:

- Standards: Complies with international safety standards, such as IEC 61508 and IEC 61511, for functional safety.

- Certification: May have certifications indicating its compliance with safety integrity levels.

- Flexibility:

- Modular Design: Allows for flexible system configuration and expansion based on specific application needs.

- Interchangeability: Modules can be replaced or upgraded with minimal system downtime.

- Integration:

- Compatibility: Designed to integrate seamlessly with Triconex safety systems, providing enhanced functionality and performance in safety-critical applications.

Application Scenarios

- Industrial Safety:

- Usage: Utilized in industrial processes where safety is critical, such as oil and gas, chemical processing, and power generation.

- Function: Provides fail-safe operation and ensures the safety of personnel and equipment.

- Process Control:

- Role: Used in process control environments to monitor and manage safety-critical processes and systems.

- Impact: Enhances process reliability and prevents accidents or hazardous situations.

- Critical Infrastructure:

- Application: Applied in critical infrastructure sectors, including utilities and transportation, where safety and reliability are paramount.

- Advantages: Ensures compliance with safety regulations and operational standards.

Additional Considerations

- Installation: Follow manufacturer’s guidelines for installation and configuration to ensure proper operation and integration with the Triconex system.

- Technical Support: For detailed information, installation assistance, or technical support, consult Triconex’s official documentation or contact their support team.