Triconex 8312

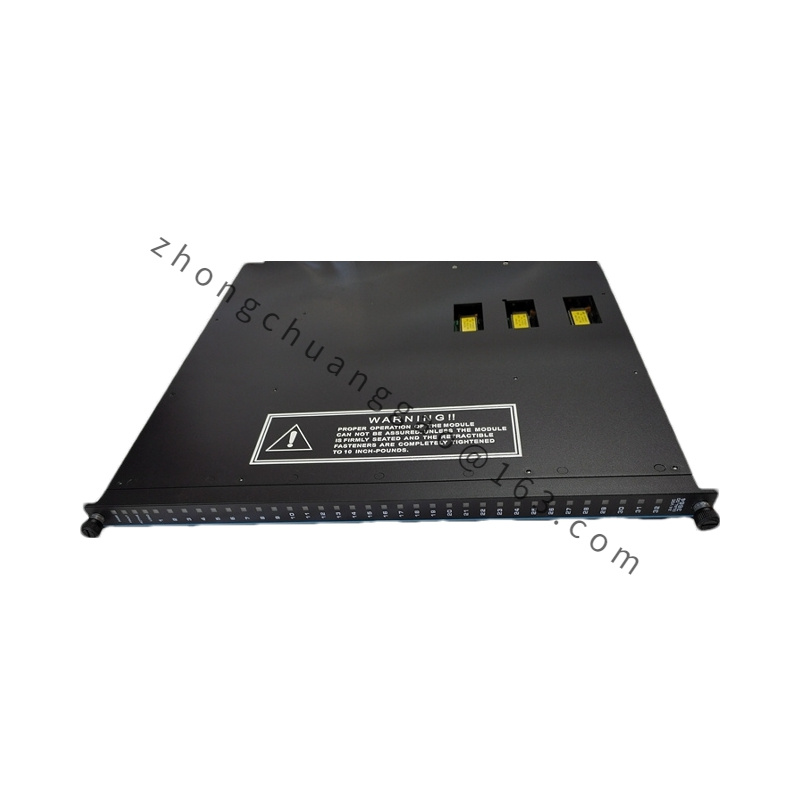

TRICONEX 8312 is a high-performance, programmable, and scalable Safety Instrumented System (SIS) input/output module manufactured by Triconex, a leading provider of industrial automation solutions. As part of the Trident series of SIS modules, it is specifically designed for industries such as industrial automation, petrochemicals, natural gas, power, and nuclear power. The module is engineered to collect field signals and output control signals, ensuring high safety and reliability in critical applications.

Detailed content

Technical Specifications

- Channels: 8 channels supporting both analog and digital input/output.

- Communication Interfaces: Supports Ethernet, RS-232, RS-485, and possibly other interfaces for communication and data exchange with other control devices, PLCs, or host computers.

- Power Consumption: Typically low, with specific values depending on the configuration and operating conditions.

- Operating Temperature: Ranges from -40°C to +70°C, suitable for a wide range of industrial environments.

- Storage Temperature: Ranges from -40°C to +85°C, ensuring stable performance even in harsh storage conditions.

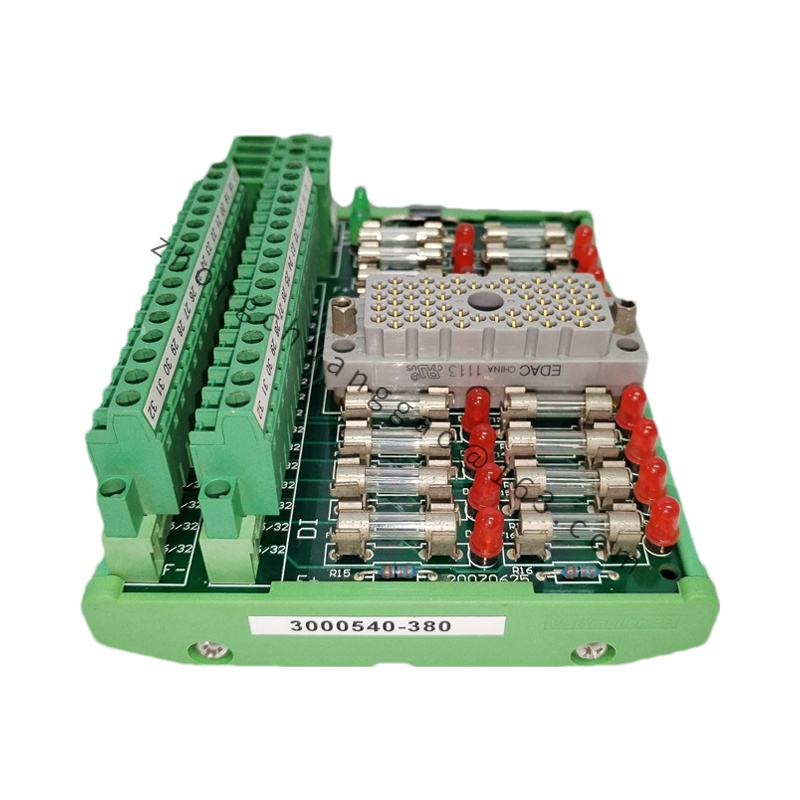

- Dimensions and Weight: Compact design with dimensions of approximately 155mm x 105mm x 30mm and a weight of 250g, making it easy to integrate into existing systems.

- Redundancy: Features multiple redundancy designs, such as Triple Modular Redundancy (TMR), to ensure high safety and reliability.

Functional Characteristics

- High Safety and Reliability: Designed with multiple redundancy and fault-tolerant features to ensure continuous and safe operation in critical industrial environments.

- Modular Design: Allows for easy maintenance, expansion, and configuration to meet specific application requirements.

- Programmable: Supports multiple programming languages, including Ladder Logic, Function Block Diagram (FBD), and Structured Text (ST), providing flexible programming options.

- Logic Processing and Decision-Making: Capable of performing logical operations, calculations, and decisions on input signals to implement simple control strategies.

- State Monitoring and Alarming: Monitors the status of input signals and triggers alarms or alerts under specific conditions, aiding operators in promptly identifying and addressing abnormalities in the system.

Application Scenarios

- Industrial Automation: Used to control and regulate various industrial equipment such as valves, actuators, and motors, enabling automation and intelligence in production processes.

- Process Control: Monitors and controls various digital signals such as flow, temperature, and pressure to ensure stability and optimization of production processes.

- Power Systems: Monitors and controls critical parameters such as switch status and circuit breaker status to ensure stable and safe operation of power systems.

- Manufacturing: Controls and monitors switch states and state changes on production lines, improving production efficiency and reducing costs.

- Equipment Monitoring and Alarming: Used in equipment monitoring and alarm systems to monitor equipment status and issue alerts in abnormal situations, ensuring safe operation of equipment.

- Building Automation: Controls and monitors lighting, HVAC systems, and security systems in commercial and residential buildings, providing intelligent building automation solutions.

- Environmental Monitoring: Monitors and controls indoor and outdoor environmental conditions such as humidity and temperature, supporting environmental protection and energy conservation efforts.