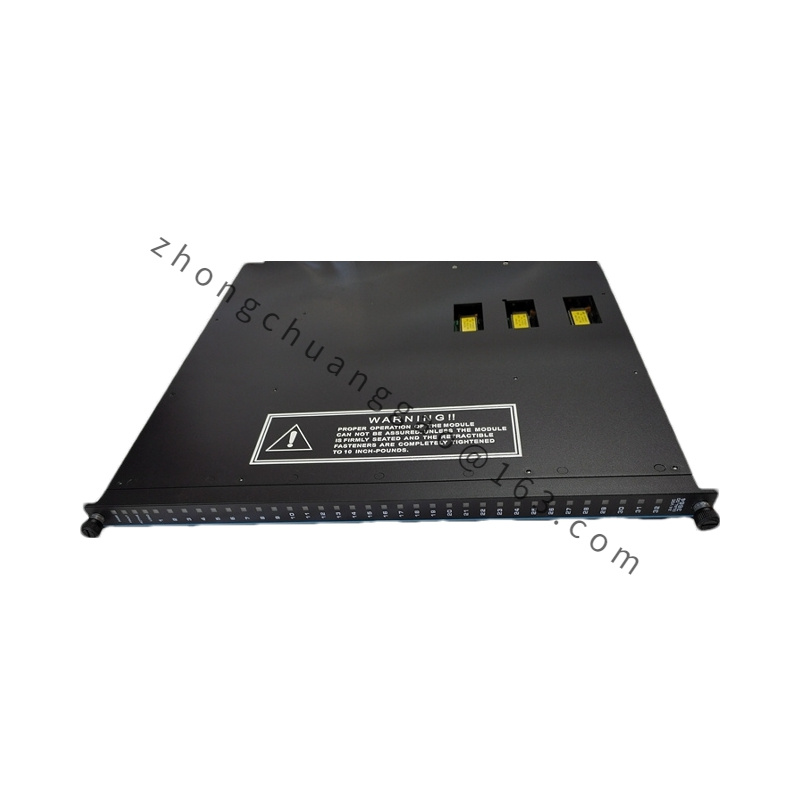

Triconex 4352B

TRICONEX 4352B is a digital input module designed for industrial automation and control systems. It is capable of receiving and monitoring digital signal inputs, making it ideal for a wide range of industrial applications. The module is known for its reliability, safety, and high performance, ensuring accurate and timely monitoring of industrial processes.

Detailed content

Technical Specifications

- Input Voltage Range: AC 85-265V, 47-63Hz; DC 24V

- Maximum Output Current: 2A

- Maximum Power: 48W

- Operating Temperature Range: 0-60°C

- Storage Temperature Range: -40°C to 85°C

- Dimensions: 152.4mm x 152.4mm x 101.6mm

Functional Characteristics

- Multiple Digital Input Channels: Provides multiple channels for receiving discrete signals from sensors or switches.

- Support for Various Input Types: Capable of handling different types of digital input signals, such as On/Off states, pulse counting, or frequency signals.

- High-Speed Sampling: Offers high-speed sampling rates for real-time monitoring and response to high-frequency signal changes.

- Redundancy Design: Features redundancy options, such as dual-channel input or multiple redundancy, to ensure high reliability.

- Hardware and Software Fault Diagnosis: Equipped with fault diagnosis functions to detect and report faults in the module or input signals.

- Programmable Configuration: Allows users to configure input channels, set thresholds, sampling intervals, and other parameters according to application needs.

- High Anti-Interference Ability: Designed to resist electromagnetic interference, ensuring stable signal acquisition and processing.

- Data Communication Interface: Provides interfaces for data communication, enabling integration with other control systems or devices.

Application Scenarios

- Safety Systems: Used in industrial safety systems to monitor the status of safety equipment, such as emergency stop buttons and safety doors.

- Process Monitoring: Monitors digital signals during production processes, including temperature, pressure, flow rate, and other parameters.

- Environmental Monitoring: Monitors environmental parameters, such as humidity and gas concentration, in environmental monitoring systems.

- Building Automation: Used in building automation systems to monitor the status of lighting, air conditioning, ventilation, and other equipment.

- Energy Management: Monitors the status of energy-consuming devices, such as electricity meters and water meters, in energy management systems.

- Production Line Control: Monitors and controls the status of production equipment to ensure stability and consistency in the production process.

- Machine Monitoring: Monitors the status of machinery and equipment, such as motors, pumps, and valves.

- Data Collection and Reporting: Collects digital signals, records historical data, and generates reports for analysis and optimization.