Triconex 4351B

Technical Specifications :

Processor and Memory: Equipped with a 32-bit processor running at 33MHz, ensuring efficient logical operations and data processing capabilities. It features 1MB RAM and 4MB flash memory, capable of storing extensive programs and data to support complex control logic.

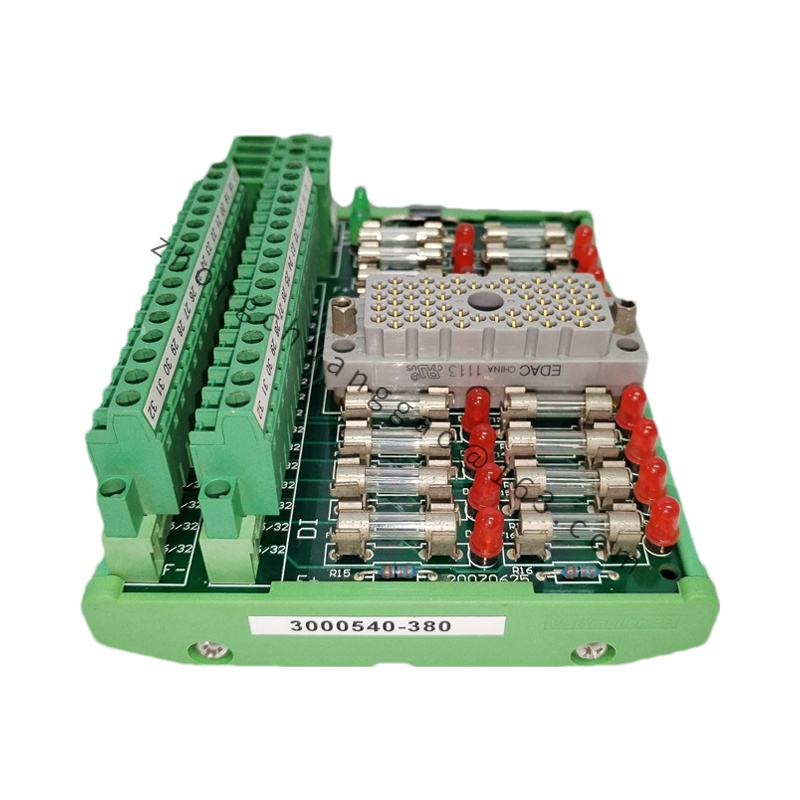

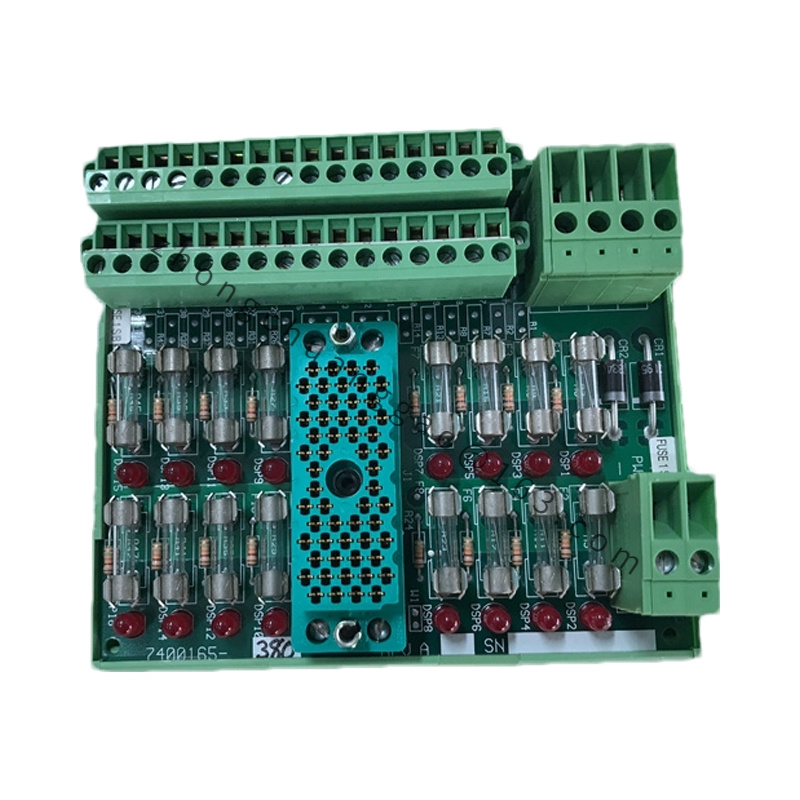

I/O Capabilities: Offers a wide range of I/O interfaces, including analog, digital, serial, and Ethernet, facilitating seamless connection and communication with various sensors and actuators.

Detailed content

Power Supply: The power module has 16 digital outputs, each capable of driving up to 1A at 24V DC, ensuring high precision and stability in digital output signals.

Communication Protocols: Supports multiple communication protocols such as Modbus, TCP/IP, ICMP, SNTP, TSAA (with IP multicast support), Trimble GPS, embedded OPC server (for 4353 and 4354 models), peer-to-peer (UDP/IP), and peer-to-peer time synchronization.

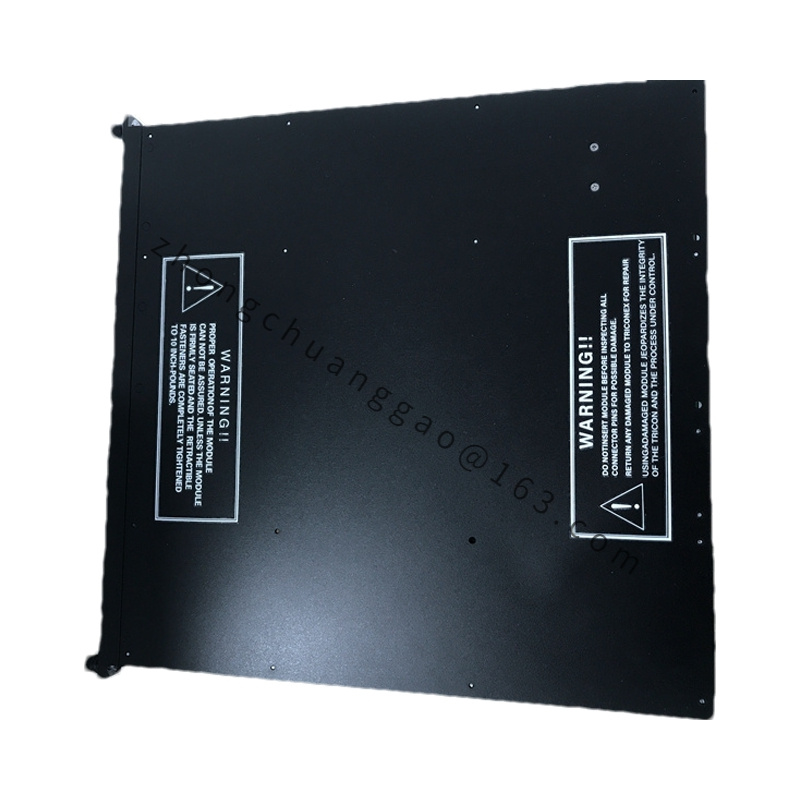

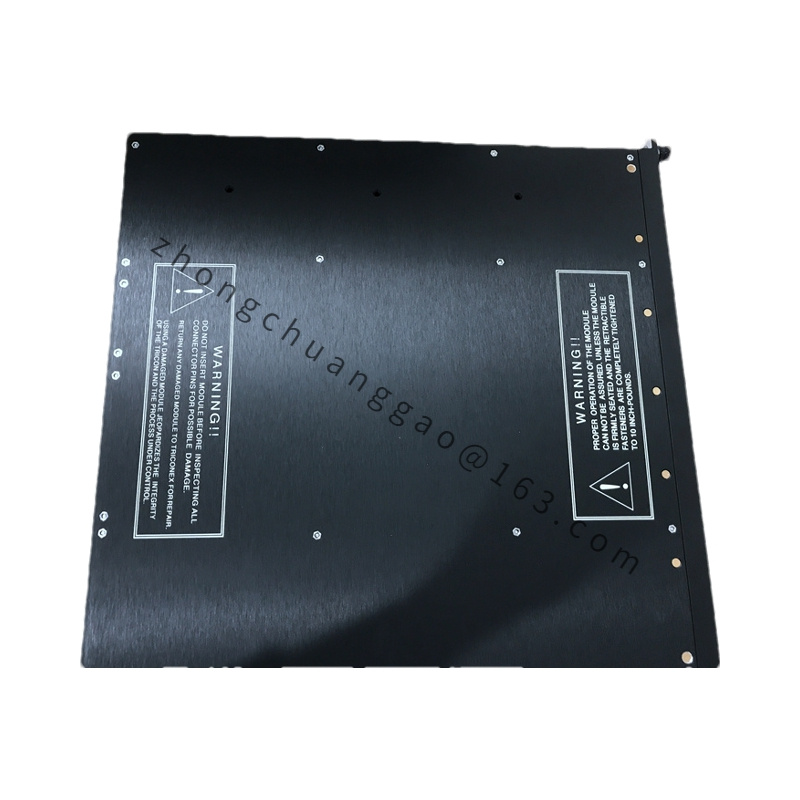

Physical Characteristics: Weighs 3.18 kg with a shipping weight of 4.5 kg.

Network and Serial Ports: Includes 2 network ports and 4 serial ports, with port isolation of 500 VDC. Serial ports support up to 115.2 Kbps, while Ethernet ports offer 10/100 Mbps (100 Mbps for 4353 model only).

Functional Characteristics :

Redundancy Architecture: Features a Triple Modular Redundancy (TMR) architecture, with three fully independent processors executing the same logic simultaneously. This ensures high availability and fault tolerance, allowing the system to continue operating even in the event of a processor failure.

Programmability: Allows users to program custom control logic and safety rules based on specific application requirements, using a dedicated programming language.

Safety and Reliability: Equipped with various safety features, including fault detection and diagnostic mechanisms, to ensure the safe and reliable operation of the system.

Modularity: Designed for easy installation, maintenance, and expansion. Users can add or replace modules as needed to meet different safety requirements.

Environmental Durability: Suitable for harsh and hazardous environments, with a temperature range of -40°C to 70°C and an enclosure rated for use in dangerous areas.

Application Scenarios :

Oil and Gas Industry: Used for automation and control of oil and gas production, transportation, and processing processes, ensuring safety and efficiency.

Chemical Industry: Monitors and controls chemical reactions, mixing, separation, and transportation processes in chemical factories and process units.

Power Industry: Monitors power generation and transmission processes in power plants and distribution systems, ensuring reliability and stability.

Pharmaceutical Industry: Automates drug production processes, ensuring compliance and quality control.

Food and Beverage Industry: Controls production lines in food processing and packaging, ensuring product safety and consistency.

Railway and Transportation: Ensures the safe operation of trains and transportation systems through railway signal control.

Water Treatment: Monitors and controls water quality, pressure, and flow in water treatment plants.

Manufacturing: Used for automated production processes, machine control, and quality testing in various manufacturing factories.

Nuclear Industry: Monitors and controls nuclear reactions and auxiliary systems in nuclear power plants and facilities.

Aerospace: Controls spacecraft and ground station systems, ensuring mission success.