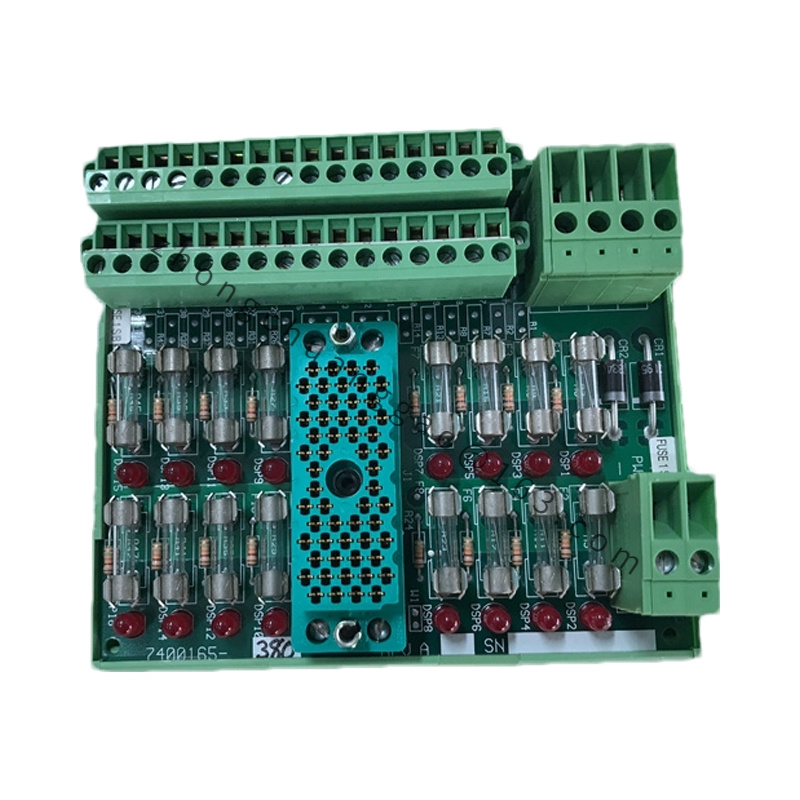

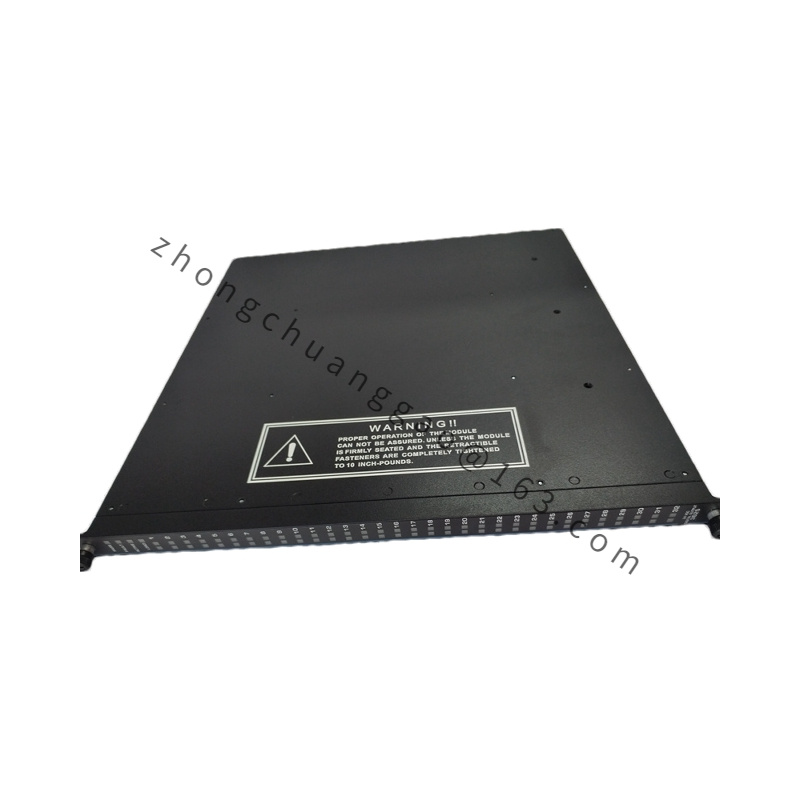

Triconex 3806E

The Triconex 3806E is a high-performance industrial control module manufactured by Invensys (now part of Schneider Electric). It is designed for use in Safety Instrumented Systems (SIS) and plays a crucial role in monitoring and controlling industrial processes. The module is known for its reliability, safety, and ability to integrate with other components within the Triconex system.

Detailed content

Technical Specifications

- Input Signals: Depending on the specific variant, the 3806E can accept analog input signals such as 4-20 mA or 20-320 mA current loops for measurement of process variables like temperature, pressure, and flow.

- Output Signals: For analog output modules, the 3806E can provide output signals in ranges such as 0-10 V, 0-20 mA, or 0-5 V, with high accuracy of ±0.1%.

- Number of Channels: The module typically features multiple input or output channels, allowing for simultaneous monitoring and control of multiple signals.

- Isolation: Input/output isolation and channel-to-channel isolation are provided to ensure system safety and stability.

- Communication: The 3806E can communicate with other components within the Triconex system, facilitating system integration and coordination.

Functional Characteristics

- Safety and Reliability: The 3806E is designed to meet high safety standards, such as IEC 62443, and incorporates triple modular redundancy (TMR) principles to ensure continuous operation even in the event of a fault.

- Programmability: The module supports programming, allowing users to configure its behavior to meet specific application requirements and logic.

- Real-Time Performance: The 3806E is capable of responding to input signals with very high speed, ensuring real-time monitoring and control.

- HART Filter: Certain variants of the 3806E include an integrated HART filter of SIL 3 quality, which can “listen” to data traffic and allow only read access to field devices, enhancing system security.

Application Scenarios

- Oil and Gas Industry: Used to monitor and control oil and gas production processes, including well control, natural gas distribution, and pipeline transportation.

- Chemical Industry: Employed in chemical factories to monitor and control chemical production processes, ensuring process safety and compliance.

- Power Industry: Utilized in power stations and grids to monitor power generation equipment and power distribution systems, and to perform emergency shutdown operations to prevent accidents.

- Pharmaceutical Industry: Used to monitor production processes, ensuring the operational safety and product quality of pharmaceutical factories.

- Food and Beverage Manufacturing: Applied to monitor and control food and beverage production lines, ensuring product quality and production efficiency.

- Manufacturing: Used to monitor and control automated production lines, mechanical equipment, and robot systems.

- Transportation: Employed to monitor and control traffic signal systems, railway signal systems, and other transportation infrastructure to ensure traffic safety.

- Water Treatment and Wastewater Treatment: Utilized to monitor and control water treatment and wastewater treatment equipment to ensure water quality and environmental compliance.