Detailed content

Technical Specifications

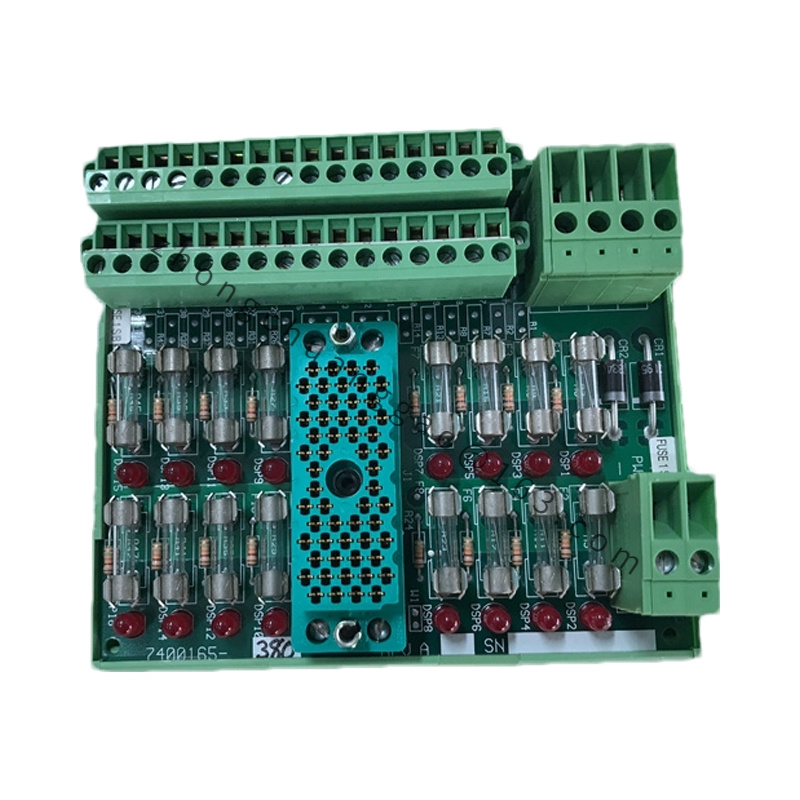

- Input Type: The 3503E module supports both analog and digital inputs, depending on the specific configuration. For digital input, it typically features 32 inputs grouped into 8 sets, with a recommended input range of 20-42.5 VDC and a maximum voltage of 42.5 VAC/VDC.

- Communication Interface: Equipped with communication interfaces for data exchange and communication with other control devices, systems, or upper-level control systems.

- Redundancy: Often designed with redundancy features, including dual processors and dual power inputs, to provide system-level redundancy and fault tolerance.

- Programmability: The module is programmable, allowing users to configure and program according to specific needs.

Functional Characteristics

- High Reliability and Safety: Utilizes reliable industrial-grade components and designs to ensure stable operation in harsh environments and stringent conditions. Incorporates fault detection, fault tolerance, and safety protection mechanisms.

- Fast Response: Possesses rapid response times and high-speed data processing capabilities, enabling real-time monitoring and control of industrial processes.

- Multiple I/O Interfaces: Offers a variety of input/output interfaces for communication and integration with other devices and systems.

- Programmable Range: Supports a programmable input signal range to accommodate different measurement needs.

Application Scenarios

- Petroleum and Natural Gas Industry: Used in emergency shutdown systems (ESD) during refinery and oil extraction processes to prevent accidents and protect employee safety.

- Chemical Industry: Aids in precise control and protection of reactors and high-pressure equipment to prevent hazards such as leaks and explosions.

- Power Industry: Provides necessary safety layers for monitoring and protecting boilers and turbocompressors in thermal power plants.

- Manufacturing Industry: Monitors machine status and process parameters in highly automated production lines to ensure production safety and efficiency.