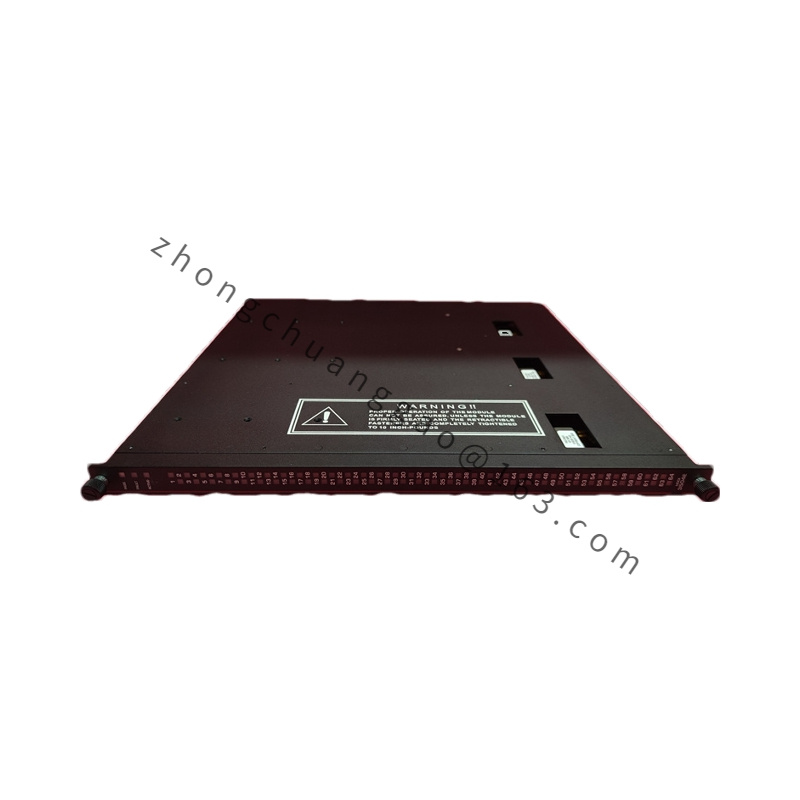

TRICONEX 3009 – Main Processor Module

- Processor: High – performance 32 – bit MIPS Cortex – M4 processor with a main frequency of up to 1.3 GHz.

- Memory: 2GB RAM, supporting hot – swap function.

- Storage: 8GB flash memory for storing programs and data.

- Communication Interfaces: Support Ethernet, RS – 232/485 serial communication, Modbus TCP/IP protocol, etc.

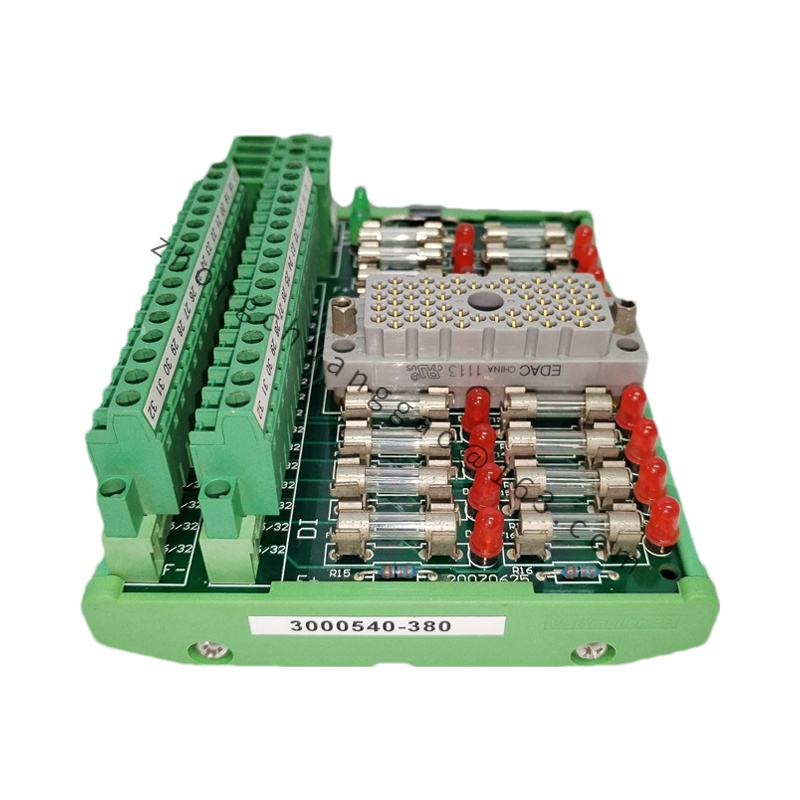

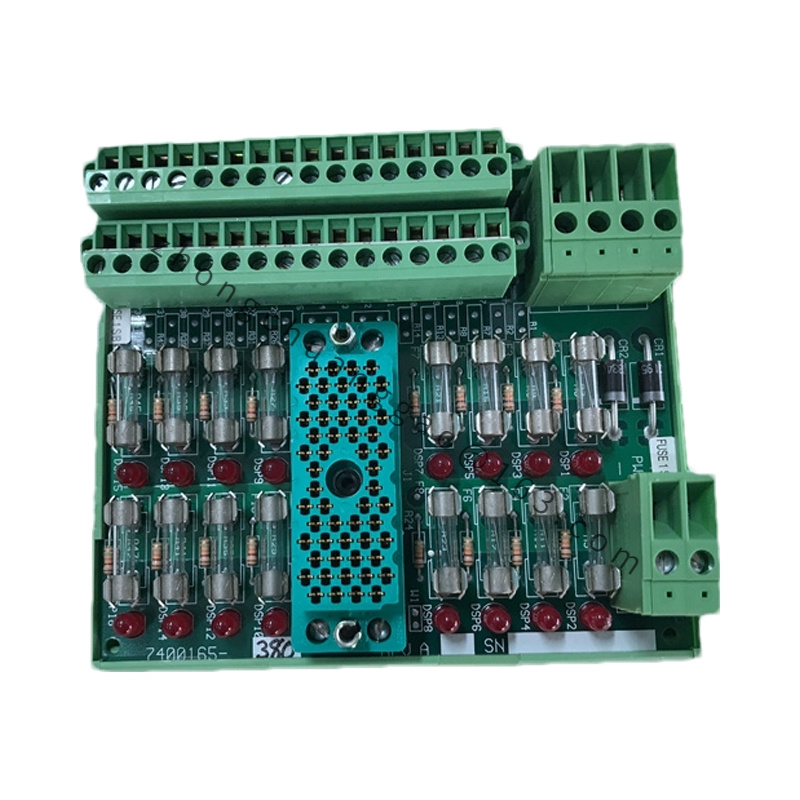

- I/O Channels: Support up to 96 I/O points, including digital input/output, analog input/output, etc.

- Operating Voltage: 24V DC input, 5V DC output.

- Operating Temperature Range: -40°C to +85°C.

- Size: 45mm x 20mm x 15mm.

- Weight: Approximately 2 kg.

- Safety Level: Meet the requirements of SIL – 3 safety integrity level.

Detailed content

- Function Features

- High – reliability Redundancy Design: Adopt a triple modular redundancy (TMR) architecture. This architecture ensures that the system can continue to operate in the event of a single – component failure, improving the reliability and fault – tolerance of the system.

- Powerful Processing Capacity: With a high – performance processor, it can support complex control algorithms and large – scale system processing, and is capable of handling a large number of control tasks and data.

- Flexible I/O Configuration: Support a variety of input/output types, which can be flexibly configured according to different industrial equipment requirements, and is suitable for connecting to various field devices.

- Advanced Diagnostic Function: Have advanced diagnostic functions, which can monitor the system status in real – time, quickly detect faults, and provide detailed fault information, facilitating maintenance and troubleshooting.

- Friendly User Interface: Provide a user – friendly human – machine interface, which is convenient for operation and maintenance personnel to configure, monitor and maintain the system.

- Safety Certification: In line with international standards such as IEC 61508 and IEC 61511, with high – level safety assurance.

- Application Scenarios

- Emergency Shutdown System (ESD): It can quickly detect abnormal conditions. When a major fault occurs, it can automatically stop the operation of the relevant equipment to prevent the expansion of the accident and ensure the safety of personnel and equipment.

- Fire and Gas Detection System: Used to monitor the leakage of fire and gas in real – time. Once a dangerous situation is detected, it can immediately send out an alarm signal and trigger the corresponding emergency treatment measures.

- Burner Management System (BMS): Control the operation status of the burner, including ignition, flame detection, load adjustment, etc., to ensure the safe and stable operation of the burner.

- Turbine Control System: Monitor and control the operation of turbine machinery, such as steam turbines, gas turbines, etc., to ensure their stable operation, and realize functions such as speed control, load adjustment, and fault protection.

- Other Industrial Automation Scenarios: Widely used in the petrochemical, power, metallurgy and other industries, for the safety control and monitoring of various industrial processes, to ensure the safe and stable operation of the production process.