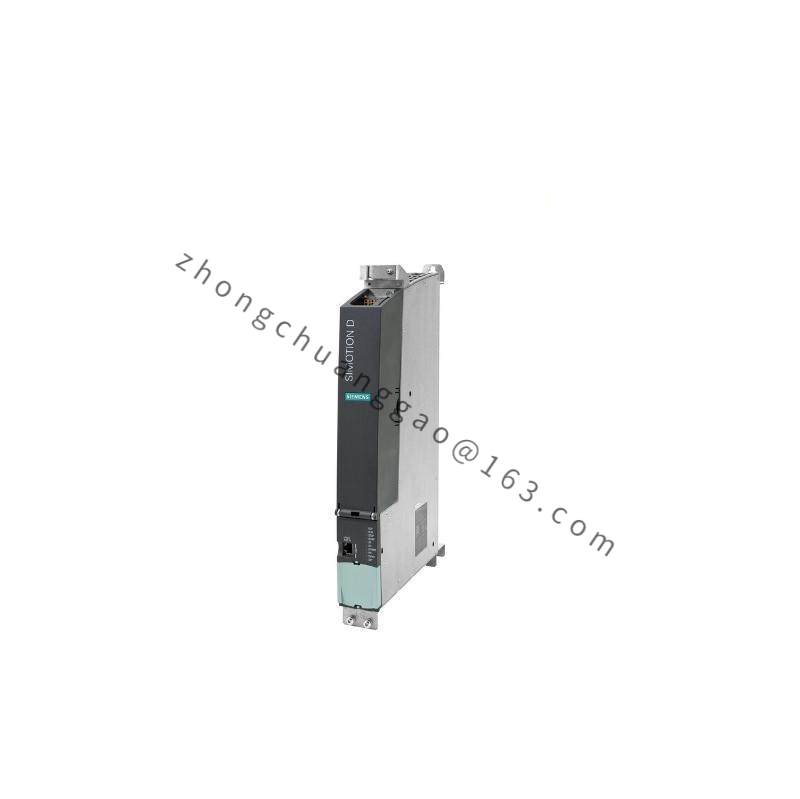

SIEMENS 6DR5220-0EN00-0AA0: Smart Electropneumatic Positioner for Advanced Control Applications

The SIEMENS 6DR5220-0EN00-0AA0 Smart Electropneumatic Positioner is a high-performance automation component designed for precision control in industrial processes. It seamlessly integrates into various applications, enhancing operational efficiency and accuracy.

Detailed content

Model Number:6DR5220-0EN00-0AA0

Type:Smart Electropneumatic Positioner

Control Protocol:Modbus TCP/IP

Actuator Compatibility:Various pneumatic actuators

Operating Pressure:0.2 to 1.0 bar

Position Accuracy:+/- 0.01°

Operating Temperature:-20°C to +70°C

Power Supply Voltage:AC 230V, 50/60 Hz

Weight:1.5 kg

The SIEMENS 6DR5220-0EN00-0AA0 is engineered to deliver exceptional precision and robustness in demanding industrial environments. Its smart electropneumatic design ensures accurate positioning of actuators, making it ideal for applications requiring high precision and reliability.

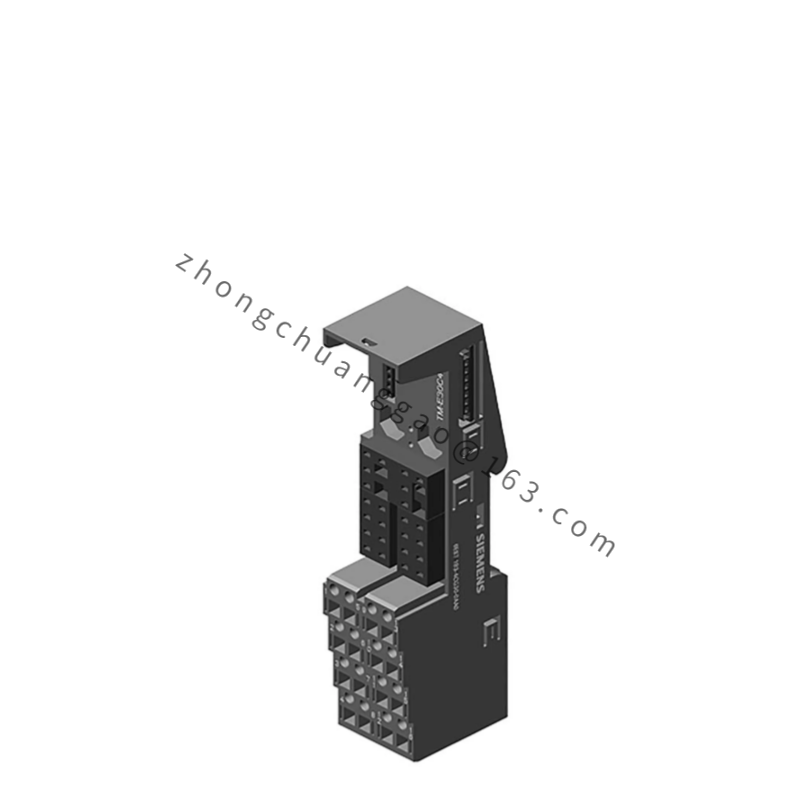

Equipped with advanced control algorithms, this positioner optimizes performance across a wide range of operating conditions, ensuring consistent and reliable operation. Its modular architecture facilitates easy integration with various industrial control systems, enhancing system flexibility and scalability.

Featuring a compact and durable construction, the 6DR5220-0EN00-0AA0 is designed for long-term reliability. It supports both analog and digital control signals, providing versatile connectivity options. With its IP65 protection class, it is suitable for harsh industrial settings, offering protection against dust and water ingress.

This product supports the Modbus RTU protocol, enabling seamless communication with a variety of industrial automation systems. It is compatible with numerous protocols, ensuring compatibility and ease of integration with existing infrastructure. Its robust electrical supply system ensures stable operation under varying environmental conditions.

The SIEMENS 6DR5220-0EN00-0AA0 comes with comprehensive diagnostic features, allowing users to monitor and troubleshoot issues efficiently. Its intuitive interface simplifies setup and maintenance, contributing to reduced downtime and improved productivity in manufacturing processes.