Detailed content

Technical Specifications:

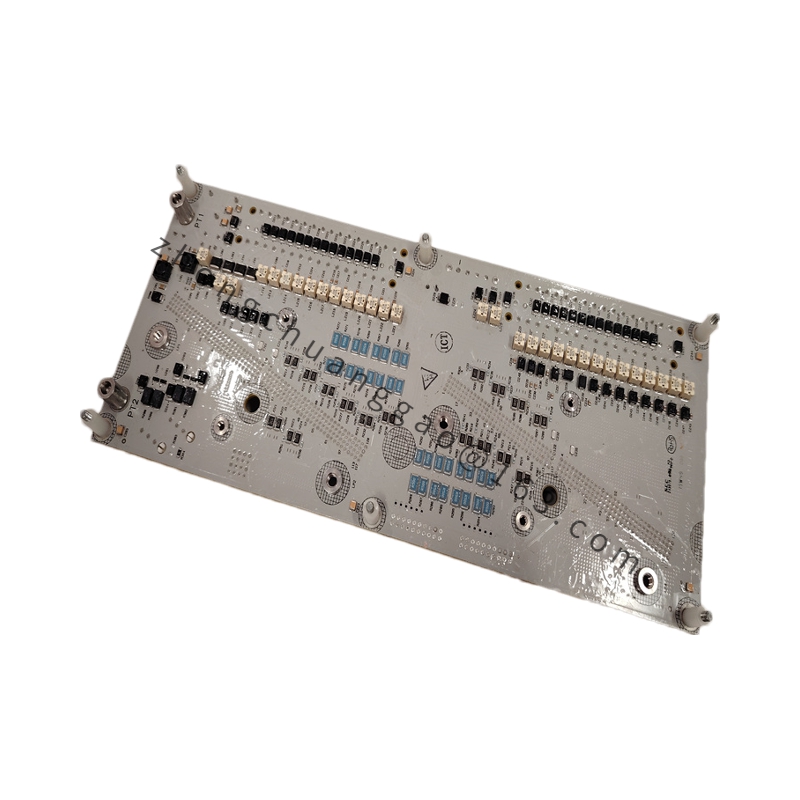

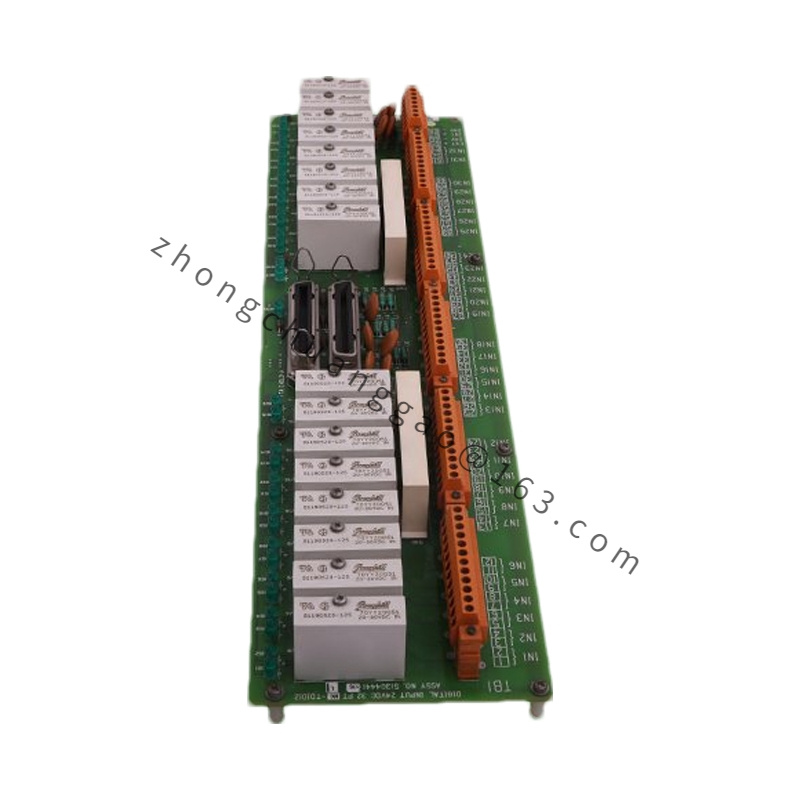

- Type: Process Control Module

- Model Number: TC-PPD011

- Function: Designed to manage and control process parameters, offering precise data acquisition and control for various industrial processes.

- Input Types: Typically supports a range of process inputs such as temperature, pressure, flow, and level sensors. The exact types and number of inputs should be referenced in the datasheet.

- Output Types: Provides analog or digital outputs to control actuators, alarms, or other field devices.

- Power Supply: Operates on a standard power supply, often 24V DC (specific voltage requirements should be verified in the datasheet).

- Communication Protocols: Supports communication protocols like Modbus, BACnet, or Honeywell’s proprietary protocols for integration with other systems.

- Temperature Range: Designed to operate in specified industrial temperature ranges; details should be confirmed in the datasheet.

- Dimensions: Compact design for installation in control panels or enclosures; exact dimensions are specified in the datasheet.

- Weight: Lightweight for ease of installation and integration (exact weight should be confirmed in the datasheet).

Features:

- High Precision: Offers accurate measurement and control of process parameters, ensuring precise operation.

- Versatile Inputs/Outputs: Supports a variety of input and output configurations to interface with different sensors and control devices.

- Robust Design: Built to withstand harsh industrial environments, including temperature extremes, vibration, and exposure to chemicals.

- Flexible Communication: Facilitates integration with existing control systems and other industrial automation components through multiple communication protocols.

- User-Friendly Interface: Features an intuitive interface for configuration and monitoring, simplifying setup and operation.

Applications:

- Industrial Process Control: Used in various industrial processes to manage and control parameters such as temperature, pressure, and flow.

- Manufacturing: Applied in manufacturing environments to ensure precise control and monitoring of production processes.

- Building Management: Integrated into building management systems for controlling HVAC, lighting, and other systems based on process parameters.

- Energy Management: Assists in energy management by providing accurate control and monitoring of energy-related processes.

- HVAC Systems: Enhances HVAC systems by providing control and monitoring for temperature and other process variables.

Installation and Maintenance:

- Installation: Designed for easy mounting and integration into control panels or systems; detailed installation procedures should be followed as per the datasheet.

- Maintenance: Regular calibration and maintenance are recommended to ensure continued accuracy and performance. Diagnostic tools and features may be included to assist with troubleshooting.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)