Detailed content

- Optical & Electrical Parameters:

- Laser Source: 633 nm wavelength (helium-neon laser).

- Sensor Type: CMOS array for interferometric signal detection.

- Input Voltage: 24 V DC ±10%.

- Power Consumption: 25 W.

- Environmental & Mechanical:

- Operating Temperature: 0°C to +40°C (extended range: -40°C to +85°C for storage).

- Protection Rating: IP54 (dust/water-resistant).

- Dimensions: 229 mm × 114 mm × 29 mm.

- Weight: 1.2 kg.

- Interfaces & Integration:

- Bus Interface: VME-compliant.

- Communication Protocols: EtherCAT, CANopen, Profibus-DP (up to 12 Mbit).

- I/O Channels: 32 digital I/O points; 4 dedicated servo control channels.

Functional Features

- Nanometer-Level Precision:

- Utilizes laser interferometry to achieve sub-nanometer resolution for surface topography, roughness, and contour measurements.

- Real-Time Signal Processing:

- Integrated DSP and FPGAs enable high-speed data acquisition (62.5 µs update rate) and closed-loop feedback.

- Dual-Axis Synchronization:

- Simultaneously measures X/Y displacements and angular deviations, critical for complex optical alignment.

- Robust Environmental Tolerance:

- IP54 rating ensures reliable operation in industrial environments with dust or moisture.

- Auto-Reconfiguration:

- Automatically reinstates settings after module replacement via ToolboxST software.

- Automatically reinstates settings after module replacement via ToolboxST software.

Application Scenarios

- Semiconductor Manufacturing:

- Measures wafer flatness, chip topography, and lithography mask alignment (±0.1 µm accuracy).

- Precision Optics:

- Characterizes lens surface profiles, prism angles, and mirror reflectivity in telescope/camera production.

- Aerospace & Automotive:

- Validates turbine blade contours, fuel injector dimensions, and aerodynamic component tolerances.

- Research & Development:

- Enables quantum optics experiments and material science studies (e.g., thin-film thickness analysis).

- Industrial Automation:

- Integrates with CNC machines for real-time toolpath calibration and quality control.

Compatible Ecosystem

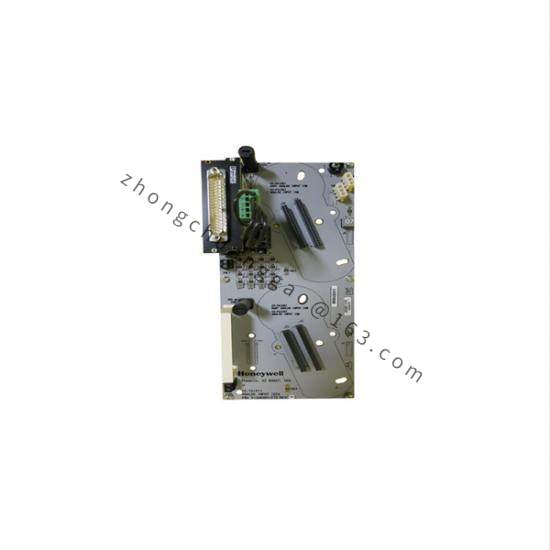

- Hardware Integration:

- Servo Drivers: WSVO modules for valve position control.

- Terminal Boards: TSVO boards for I/O signal routing.

- Controllers: GE Mark VIe, KUKA KR C2 cabinets.

- Software Tools:

- ZYGO MASS Suite: CODESYS-based environment for IEC 61131-3 programming and diagnostics.

- ToolboxST: Configures Ethernet parameters and motion profiles.

Installation & Maintenance

- Deployment Guidelines:

- Mount on DIN rails with ≥50 mm clearance for heat dissipation.

- Isolate from high-vibration machinery to prevent signal interference.

- Preventive Maintenance:

- Bi-annual inspections: Clean laser optics, verify encoder cables, and test redundant Ethernet ports (ENet1/ENet2).

- Troubleshooting:

- Signal Drift: Recalibrate laser interferometry paths.

- Overheating: Ensure ambient temperature ≤40°C and adequate ventilation.

Certifications & Support

- Compliance: CE, UL, RoHS.

- Warranty: 12-month manufacturer coverage.

- Technical Support: Global service via ZYGO-certified engineers; expedited shipping (e.g., DHL/SF Express).