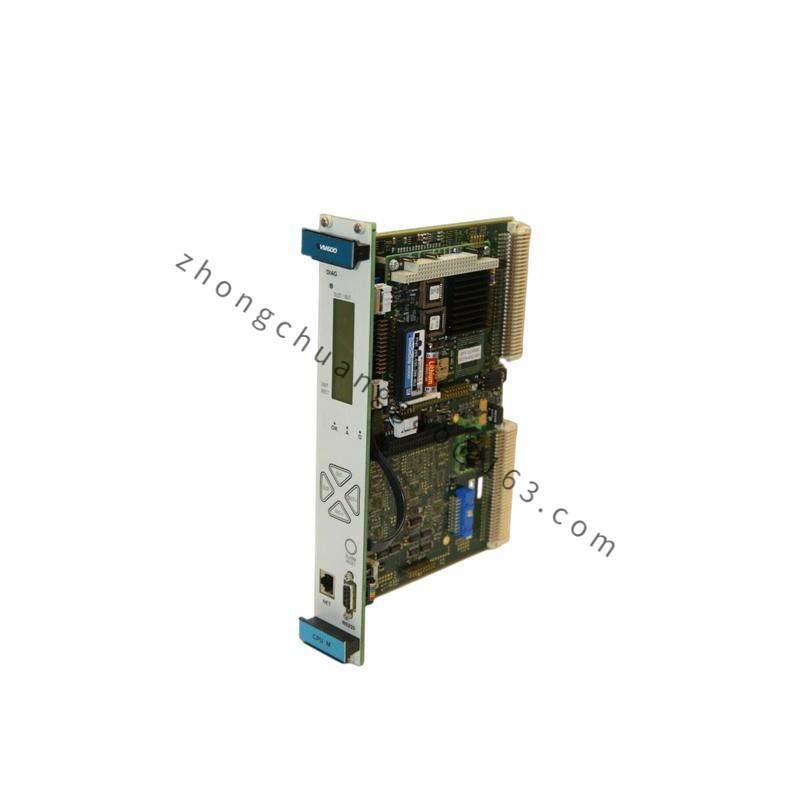

WOODWARD 9905-463 SPEED CONTROL MODULE, Designed for Precision Engine Control

The WOODWARD 9905-463 Speed Control Module is a high-performance industrial solution designed for precision speed control in demanding environments, ensuring optimal performance across a wide range of applications.

Detailed content

Product Type:Speed Control Module

Weight:0.5 kg

Operating Frequency Range:50 Hz

Input Voltage:AC 110-240V

Output Current:Up to 5A

Control Mode:Digital PID

Communication Interface:RS485

Operating Temperature:-20°C to +70°C

Humidity Range:0% to 95% RH (non-condensing)

The WOODWARD 9905-463 Speed Control Module is a critical component in modern industrial automation systems, designed to offer unparalleled precision and reliability in speed control applications. It is engineered to seamlessly integrate with various industrial machinery and equipment, providing a versatile solution for diverse operational requirements.

Crafted from high-quality materials, this module ensures durability and robust performance under challenging industrial conditions. Its compact design and lightweight construction facilitate easy installation and maintenance, minimizing downtime and maximizing operational efficiency.

With its advanced communication interface, the WOODWARD 9905-463 module supports seamless data exchange with other system components, enabling real-time monitoring and control. This feature is crucial for enhancing productivity and optimizing energy consumption in manufacturing processes.

Featuring a wide input voltage range, the module is compatible with a broad spectrum of power sources, ensuring compatibility and flexibility across different industrial settings. Its precise control capabilities are further complemented by its ability to handle varying loads, making it suitable for a wide array of applications, from conveyor systems to pump drives.

In addition to its core functionality, the WOODWARD 9905-463 Speed Control Module is equipped with safety features and diagnostics tools, ensuring user safety and facilitating proactive maintenance. This not only extends the lifespan of the module but also minimizes the risk of system failures, contributing to a more efficient and safer working environment.