Digital guide

You are here:

- Home

- Vibro-Meter

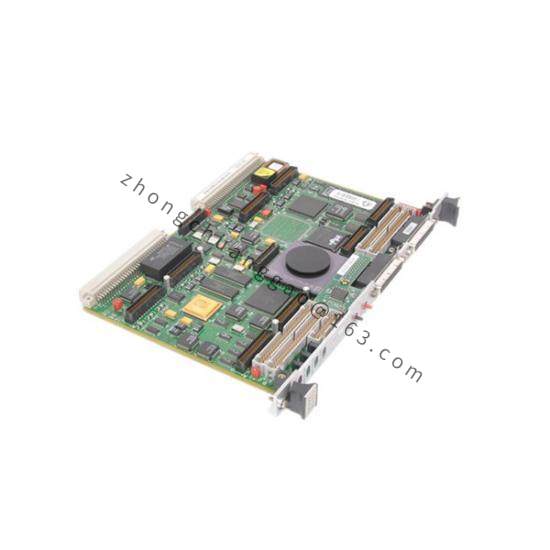

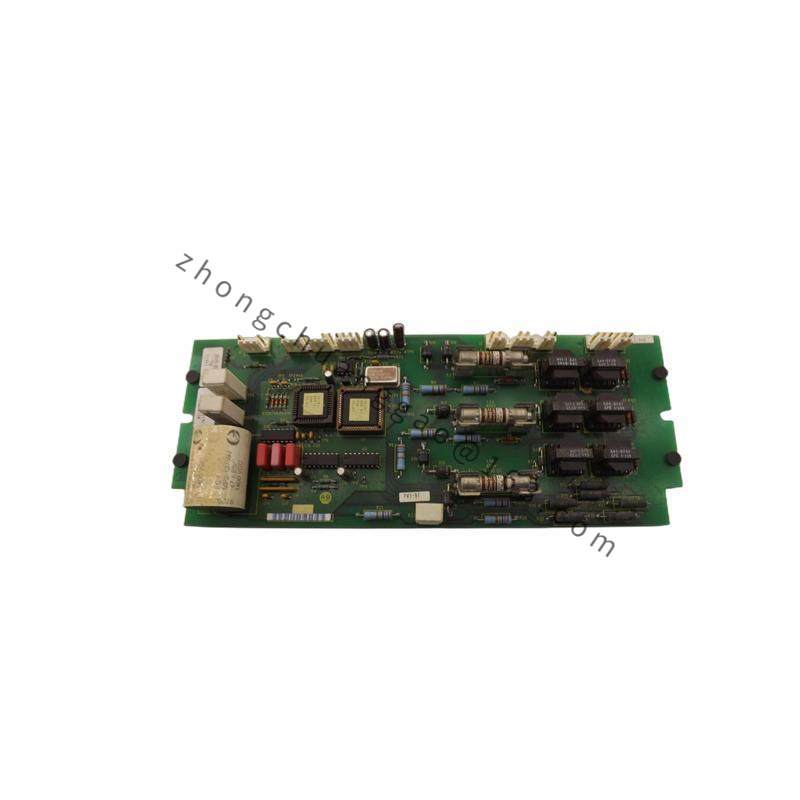

- Vibro-Meter VM600 MPC4 (Models 200-510-071-113 & 200-510-111-034)

Vibro-Meter VM600 MPC4 (Models 200-510-071-113 & 200-510-111-034)

- Technical Specifications

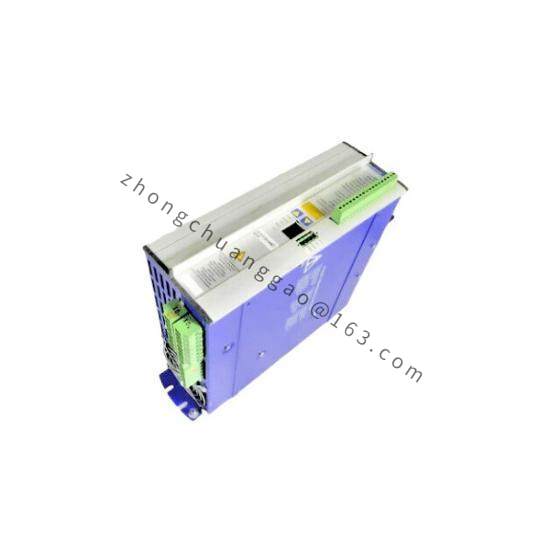

- Power Supply: It usually uses 220V AC power supply, and there is also a 24V DC power – supply model.

- Input Channels: It has 4 dynamic channels and 2 phase – reference channels or tachometer channels, which can receive signals from various transducers.

- Output: Each dynamic channel has 2 processed outputs, each dual – channel has 1 processed output, and each tachometer channel has 1 processed output.

- Communication Interface: It supports standard RS485/Modbus, and can also communicate via Ethernet and USB. The communication distance can reach up to 1200 meters.

- Frequency Range: The measurable frequency range is 0 – 20kHz, and the sampling rate can be up to 51.2kHz.

- Operating Temperature: It can work in the environment of – 10°C to 60°C or – 20°C to 70°C.

- Humidity Range: It can adapt to the humidity range of 0% – 95%.

- Protection Class: The protection class is IP65, which has good dust – proof and water – proof performance.

- Certification: It has passed CE, UL, IECEx and other certifications.

- Size and Weight: The size is about 100mm x 50mm x 30mm, and the weight is about 0.4kg or 2.9kg.

Detailed content

- Function Features

- High – precision Monitoring: With 12 – bit analog input channels, it can accurately collect and process data, and monitor various parameters of rotating machinery with high precision.

- Versatile Channel Configuration: The configuration of 4 dynamic channels and 2 phase – reference channels enables it to be suitable for the monitoring of various types of machinery, and can measure relative and/or absolute vibration and other parameters.

- Reliable Performance: It is made of high – quality materials, with a robust design, which can withstand harsh industrial environments, and has a long service life.

- Easy to Integrate: The PLC – based design can be seamlessly integrated with the existing industrial control system, and can be used in conjunction with the VM600 MPSx software.

- Self – diagnosis and Alarm Function: It has a comprehensive diagnostic function, which can detect the abnormal operation of the module and connected equipment, and send out real – time alarms, which is convenient for maintenance and troubleshooting.

- Application Scenarios

- Power Generation Industry: It is used to monitor the vibration level of turbines, generators, pumps and other equipment to ensure the stable operation of the power generation system and help detect the early signs of equipment failure.

- Oil and Gas Industry: It is applied to the vibration monitoring of compressors, pumps and other key equipment in oil and gas production, transportation and processing to ensure the safe and efficient operation of the production process.

- Manufacturing Industry: In the manufacturing industry, it is used for the condition monitoring of various rotating machinery, such as motors, machine tools, etc., which is helpful to optimize the maintenance plan and improve production efficiency.

- Aerospace Industry: It can be used for the vibration monitoring of aerospace – related equipment, and is of great significance to ensure the reliability of equipment operation and the safety of the flight process.