Digital guide

You are here:

- Home

- Other brands

- Vibro-meter 200-570-000-014 200-570-101-013

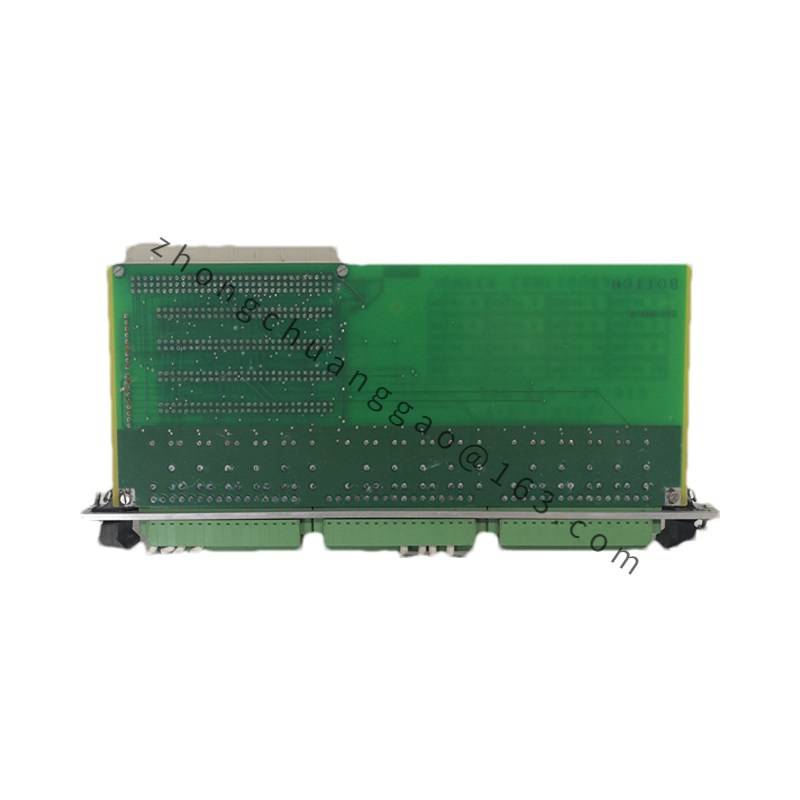

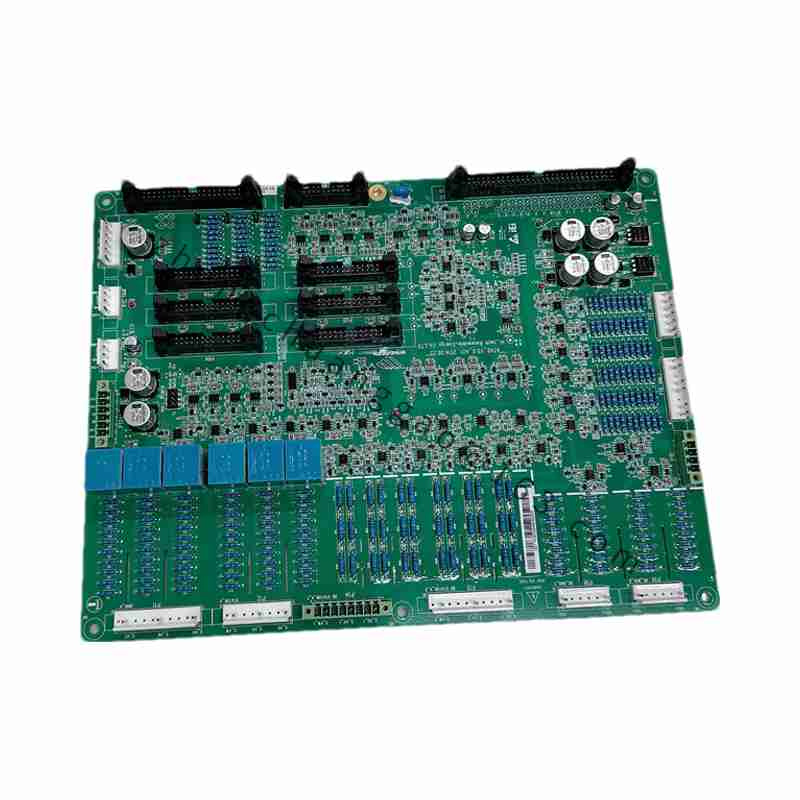

Vibro-meter 200-570-000-014 200-570-101-013

The Vibro-meter 200-570-000-014 and 200-570-101-013 are servo motor modules or controller modules designed for industrial applications, particularly those requiring high precision and reliability. These modules are built on the foundation of the 1900 series, offering enhanced measurement capabilities and operational flexibility.

Detailed content

Technical Specifications

- Model Numbers: 200-570-000-014, 200-570-101-013

- CPU: May include a 32-bit or higher processor for advanced computational tasks (specific CPU details may vary by configuration and application)

- Communication Interfaces: Support for protocols such as EtherCAT, CANopen, and Modbus, allowing for seamless data exchange and synchronization with other devices and systems.

- Frequency: Up to 1000HZ for certain applications.

- Channels: Dual channels for redundancy and increased reliability.

- Local Area Network (LAN): Compatibility with Windows-based systems for easy integration into existing networks.

Functional Characteristics

- High-Performance Motion Control: Capable of precise position, speed, and torque control with rapid response times.

- High Efficiency: Designed for high power output and efficient energy conversion.

- Multi-Specification Options: Available in various sizes and specifications to cater to different application needs.

- High-Precision Position Feedback: Equipped with encoders or Hall sensors for accurate position information and closed-loop control.

- Remote Communication & Diagnostics: Support for remote configuration, diagnostics, and data monitoring via RS485 or Ethernet connections.

- Alarm Management: Provides NAMUR-compliant relay functionality for remote transmission of alerts and messages.

- Data Acquisition & Monitoring: Capable of connecting to sensors and devices to acquire data such as temperature, pressure, and flow rates.

- Logic Control: Performs basic logic operations like switching, comparison, and calculation based on input data.

- Built-In Protection: Features overcurrent, overheat, and overload protection for safe operation.

- Redundant Positioning System: Ensures high availability and reliability in critical applications.

Application Scenarios

- Industrial Automation: Ideal for automated machinery and processes requiring precise motor control.

- Process Control: Suitable for monitoring and controlling industrial processes in sectors like oil and gas, power generation, and chemicals.

- Manufacturing: Used in manufacturing lines for assembly, packaging, and other automated tasks.

- Power Plants: Critical for the operation of turbines and other large machinery in power generation facilities.

- Refineries and Petrochemical Plants: Essential for the control and monitoring of various processes and machinery in these environments.

.jpg)