OKUMA ER-JG-7200D CNC Vertical Machining Center, High Precision, Robust Design, Advanced Automation

The OKUMA ER-JG-7200D is a high-performance CNC machine designed for precision manufacturing tasks in various industries, including automotive, aerospace, and medical sectors. It offers unparalleled accuracy and reliability in complex machining operations.

Detailed content

Max Cutting Speed:40,000 rpm

Spindle Taper:BT40

Table Size:800 x 600 mm

Workpiece Handling Capacity:Max. 2000 kg

Machine Size:2400 x 2200 x 2200 mm

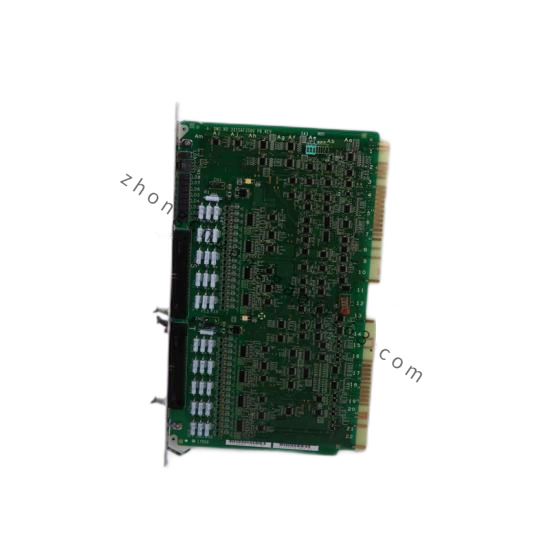

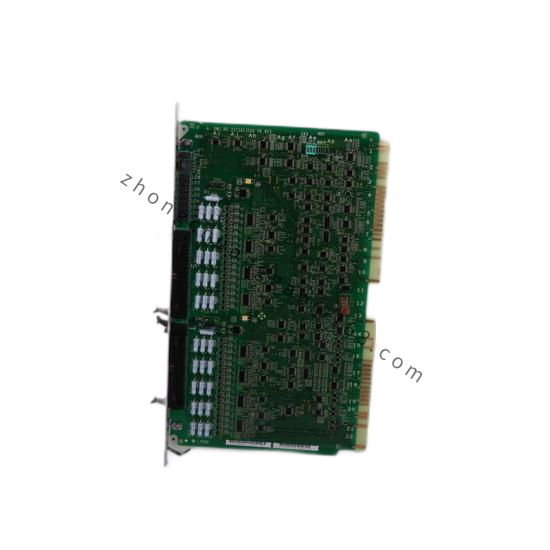

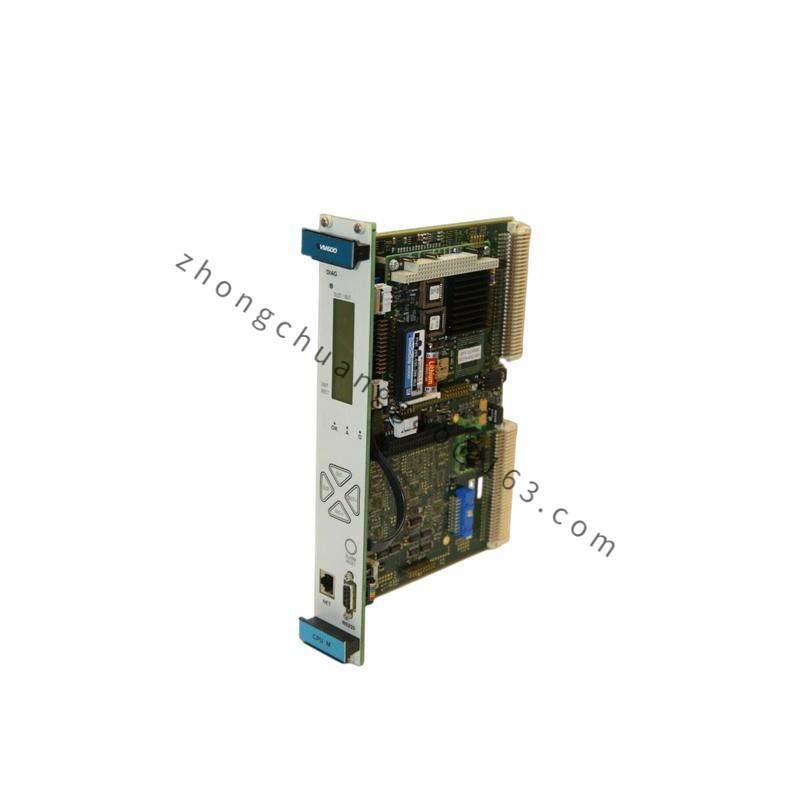

CNC System:Okuma OSP-F Series

Number of Axes:4 Axis (X, Y, Z, C)

Coolant Options:MQL (Minimum Quantity Lubrication) and Flood

Precision:0.005 mm ±0.003 mm

Software Compatibility:Windows 10 or higher

Introducing the OKUMA ER-JG-7200D, a versatile CNC vertical machining center designed to elevate your manufacturing capabilities. This machine boasts a compact footprint with an impressive work envelope that spans up to 720 x 600 x 500 mm, making it ideal for processing a wide range of complex parts.

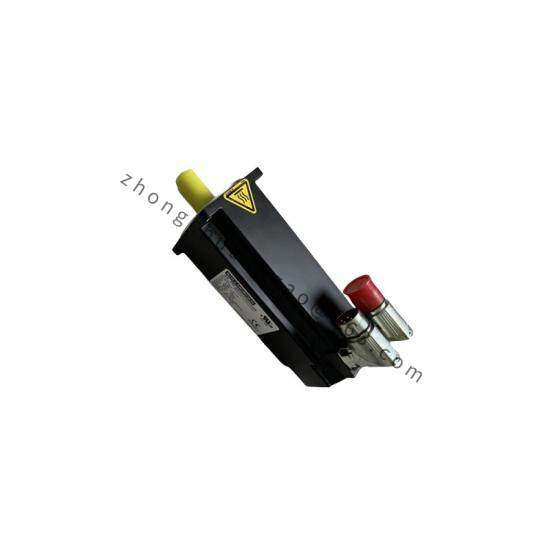

Equipped with a high-speed spindle that operates at speeds ranging from 4,000 to 18,000 rpm, this machine ensures unparalleled accuracy and productivity. It comes with a tool capacity of 24 tools, allowing for efficient tool changes and enhanced operational flexibility.

The OKUMA ER-JG-7200D is engineered with precision at its core. Its X-Y-Z travel dimensions ensure that even the most intricate geometries can be accurately machined, while the BT40 taper spindle accommodates a variety of cutting tools.

For heavy-duty applications, the machine is equipped with a robust cutting torque of 180 Nm, enabling it to handle challenging materials and demanding operations. With a maximum cutting depth of 400 mm, it’s capable of producing parts of significant size.

Efficiency is further maximized through its power consumption of 12 kW, striking a balance between performance and energy efficiency. Weighing in at a substantial 10,000 kg, the ER-JG-7200D offers a sturdy base for stable and reliable operation, ensuring long-term durability and precision.