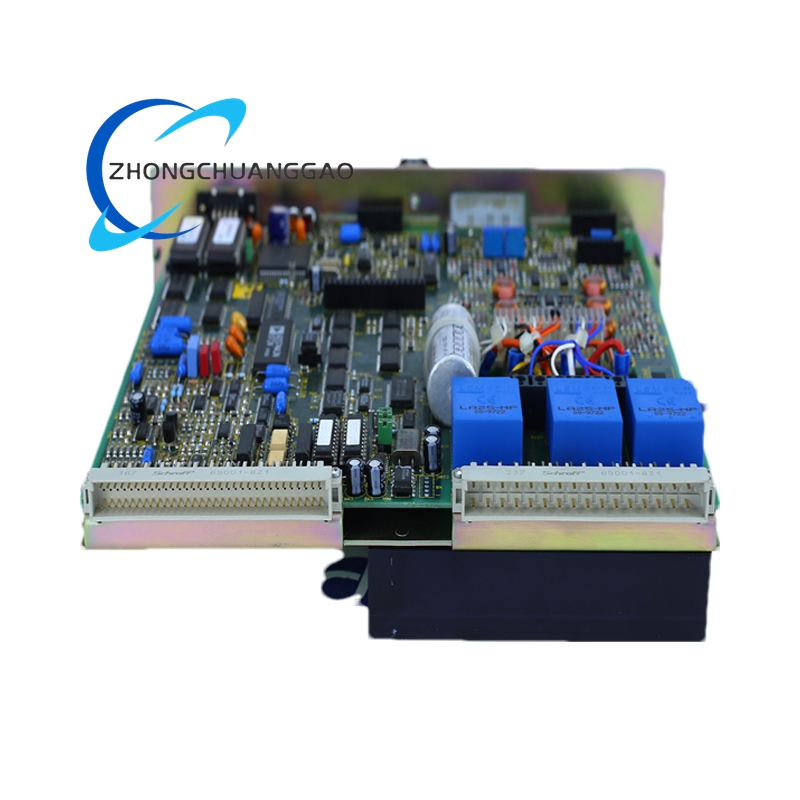

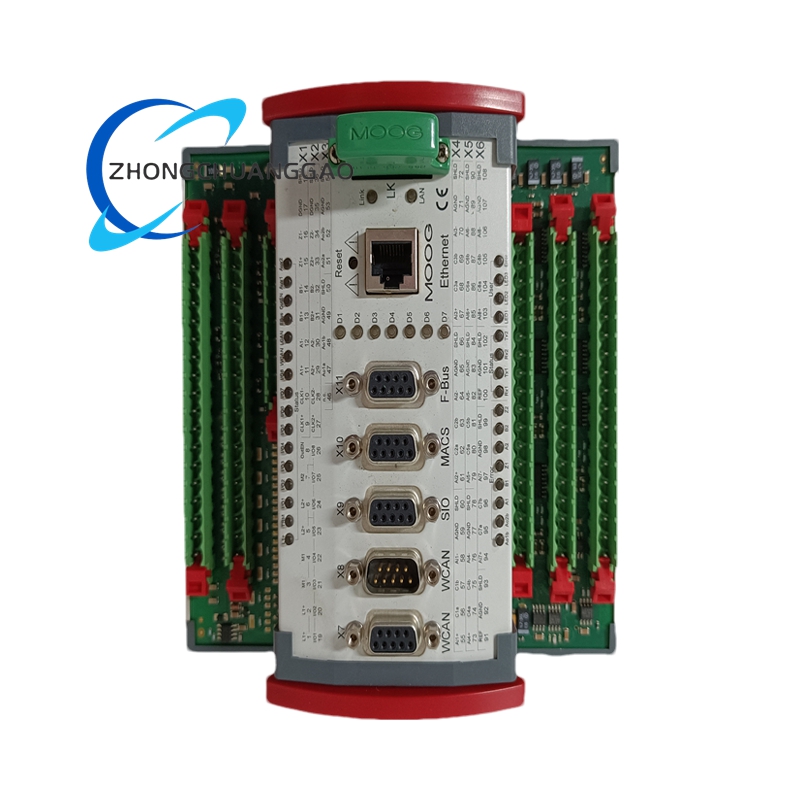

Moog G772K619A Series Servo Valve

- Product Introduction: It is a high-performance servo valve of Moog’s G772 series, which is newly manufactured and packaged in the original factory, with a 12-month factory warranty. It adopts advanced design and manufacturing technology to provide high-precision and high-reliability control for various industrial systems.

Detailed content

- Technical Specifications: The valve design is a 2-stage type with spool and bushing, and the pilot valve is a nozzle flapper. The mounting surface conforms to ISO 10372 – 03 – 03 – 0 – 92, and it can be installed in any orientation (fixed or movable). The weight is 0.86 kg (1.9 lb). The storage temperature range is – 40 to +60 °C (- 40 to +140 °F), and the ambient temperature range is – 40 to + 135 °C (- 40 to + 275 °F). The vibration resistance is 30 g, 3 axis, 10 Hz to 2 kHz, and the shock resistance is 30 g, 3 axis. The seal material is fluorocarbon (FKM) (Viton™ B) 90 shore.

- Functional Features: The 2-stage design with a dry torque motor is compatible with many different fluids. The low-friction, double-nozzle pilot stage with a symmetrical structure provides maximum stability under various conditions. It has high spool control force, which can achieve stable and consistent flow, thus improving control accuracy. The high dynamic performance can increase the production cycle. The rugged and long-life design reduces maintenance and downtime. It also has high resolution and low hysteresis, which improves the accuracy of close-tolerance applications. It is set up at the factory for easy installation and setup. The intrinsically safe or explosion-proof version can be used in most hazardous environments. The field-adjustable null bias can be adjusted for perfect alignment when replacing equipment. When the electrical signal is lost, it will return to the zero position, realizing fail-safe and predictable safe operation.

- Application Scenarios: It is suitable for the oil and gas industry, such as controlling the hydraulic system of oil well drilling equipment and oil pipeline valves, to ensure the safety and efficiency of oil and gas exploration and transportation. It is also used in the marine industry to control the hydraulic system of ships, such as the control of rudder and propeller, to ensure the navigation safety and maneuverability of ships. In addition, it can be applied to the hydraulic control system of industrial robots to improve the movement accuracy and stability of robots.