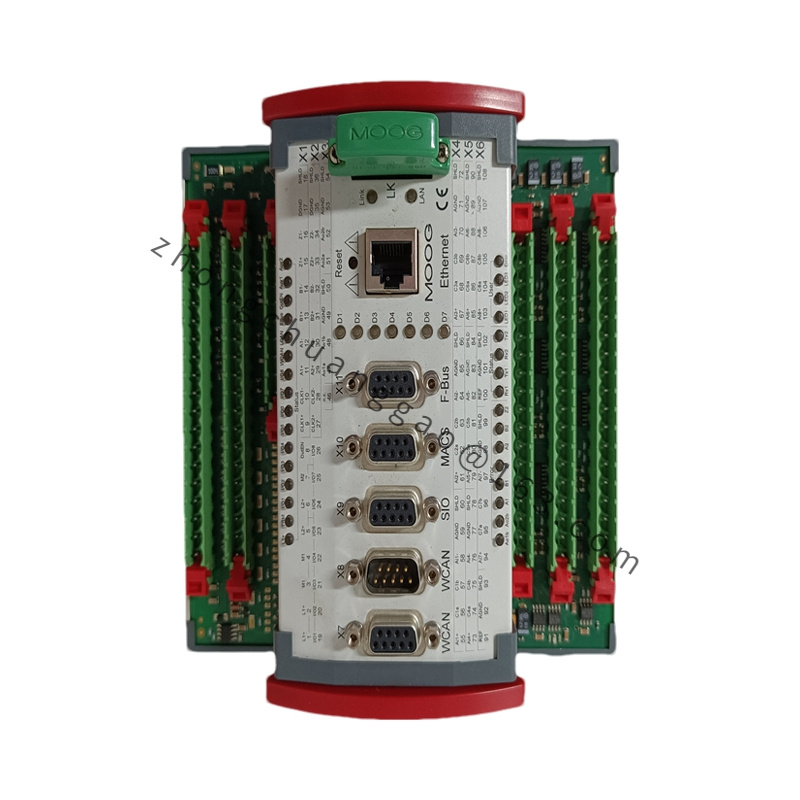

Moog G761-3009A Electro-Hydraulic Servo Valve

Technical Specifications:

- Flow Rate: 38 L/min (at a pressure drop of 70 bar)

- Maximum Operating Pressure: 315 bar (4500 psi)

- Frequency Response: 90–180 Hz (±10% signal, -3 dB)

- Step Response: 6–9 ms (valve spool transitioning from 0 to fully open at 210 bar pilot pressure)

- Resolution: <0.5%

- Hysteresis: <3%

- Signal Range: ±15 mA, ±40 mA, or ±200 mA (configurable)

- Mounting Interface: ISO 10372-04-04-0-92 (standard for hydraulic systems)

- Port Configuration: Four-way, three-position throttling for versatile flow control

Detailed content

Functional Characteristics:

- High Dynamic Performance: The nozzle-flapper pilot stage and mechanical feedback mechanism enable rapid, accurate control of hydraulic parameters (position, velocity, acceleration, force).

- Low Hysteresis and High Resolution: Minimizes deadband and ensures precise tracking of input signals.

- Rugged Design: Built to withstand harsh industrial environments, reducing maintenance needs.

- Compact Form Factor: Optimized for installations with spatial constraints.

- Safety Compliance: Available in intrinsically safe variants (e.g., G761K) for hazardous environments.

Applications:

- Material Testing Machines: Precision control of load and displacement during tensile, compression, or fatigue tests.

- Seismic Simulation Systems: Accurate replication of ground motion profiles for structural testing.

- Metallurgical Equipment: Flow and pressure regulation in aluminum cold rolling mills and other metal forming processes.

- Power Generation: Control of hydraulic actuators in hydroelectric turbines and steam valve systems.

- Industrial Automation: Integration into hydraulic systems for robotics, CNC machinery, and injection molding.

Key Advantages:

- Reliability: Proven performance in demanding industrial settings.

- Flexibility: Configurable signal ranges and mounting options adapt to diverse systems.

- Efficiency: Reduces energy consumption through precise flow control.

- Global Support: Backed by Moog’s network of technical experts and service centers.