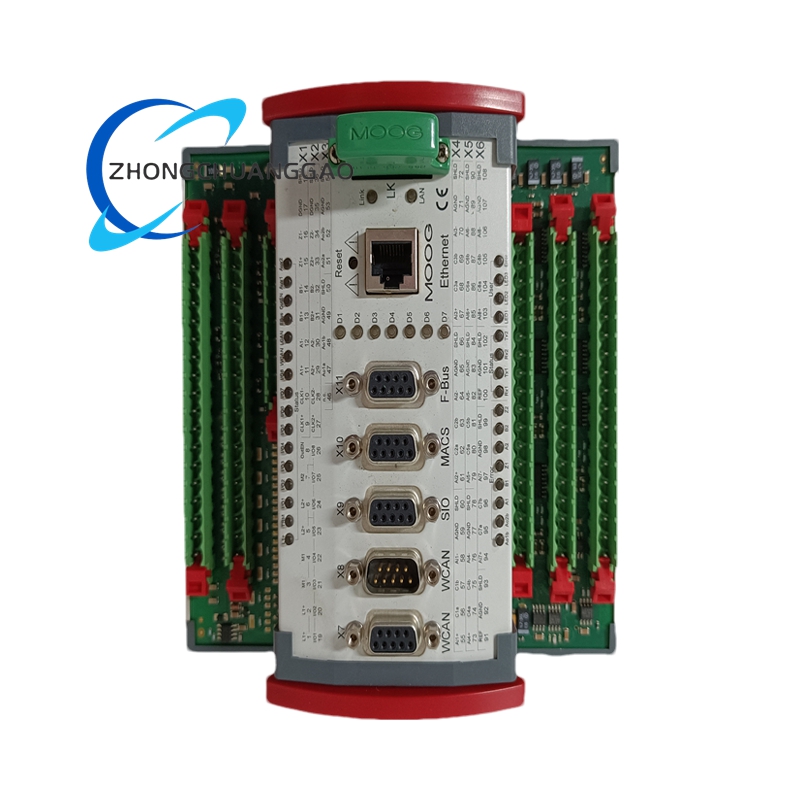

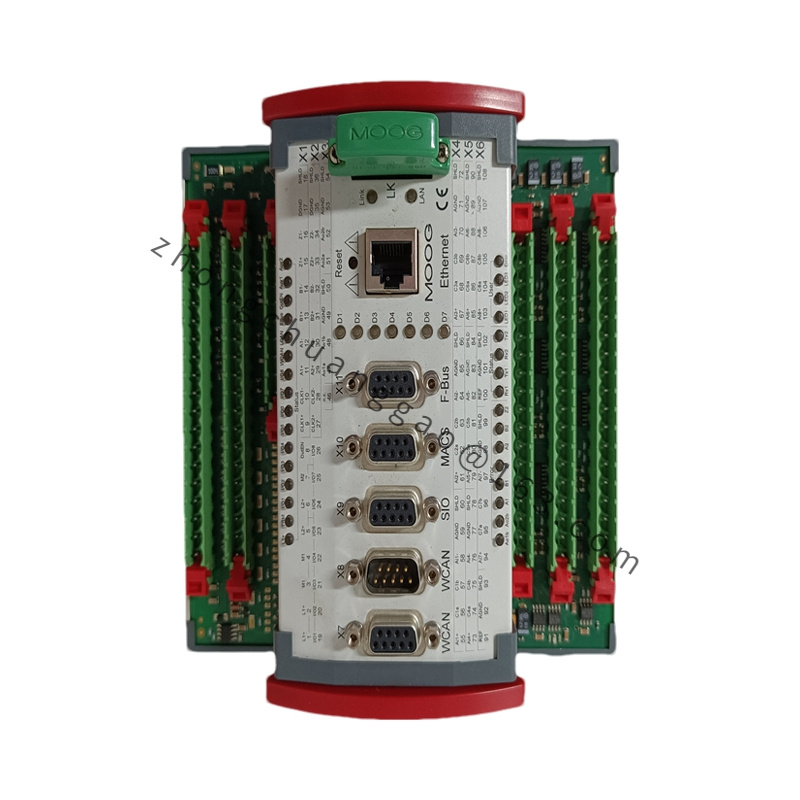

Moog G631-3601B Electro-hydraulic Servo Valve

- Product Introduction: It is a high-performance two-stage electro-hydraulic servo valve in the Moog G631 series. It can be used as a three-way and four-way throttle-type flow control valve, and has better control performance when used as a four-way valve. The valve has the advantages of simple structure, firmness, reliable operation, and long service life, and all data have been adjusted at the factory to ensure performance stability.

Detailed content

- Technical Specifications: The rated flow rate is 5 L/min to 75 L/min under a rated pressure drop of 7 MPa. The pilot stage is a symmetrical double-nozzle flapper valve, driven by a dry-type double air gap torque motor, and the output stage is a four-way slide valve. The installation size complies with the ISO 4401 standard. The minimum supply pressure is 1.4 MPa, the maximum is 31.5 MPa, the pressure at port P can withstand up to 46.5 MPa, and the pressure at port T is 21 MPa. The spool displacement is 1.27 mm, and the driving area of the valve element is 75 mm². The rated signal is 30 to 150 mA (single coil), the frequency response is 75 Hz (at 90° phase lag), and the 100% step response time is 18 ms (at a system pressure of 3,000 psi). The weight is 2.2 kg.

- Functional Features: It adopts a dry-type torque motor and a two-stage hydraulic amplifier structure. The pilot stage is a low-friction double-nozzle flapper valve, which has the advantages of high resolution and low hysteresis. The valve core has a large driving force. The fifth port can be selected to independently control the pilot valve, and the disc filter of the pilot valve can be replaced on-site, which is convenient for maintenance. It has a solid and long-life design, and can still maintain high accuracy and reliable operation in harsh industrial environments.

- Application Scenarios: It is suitable for industrial fields that require high control accuracy and stability, such as metal processing equipment, plastic injection molding machines, hydraulic test benches, etc., and can be used in electro-hydraulic control systems that require precise flow and pressure control.