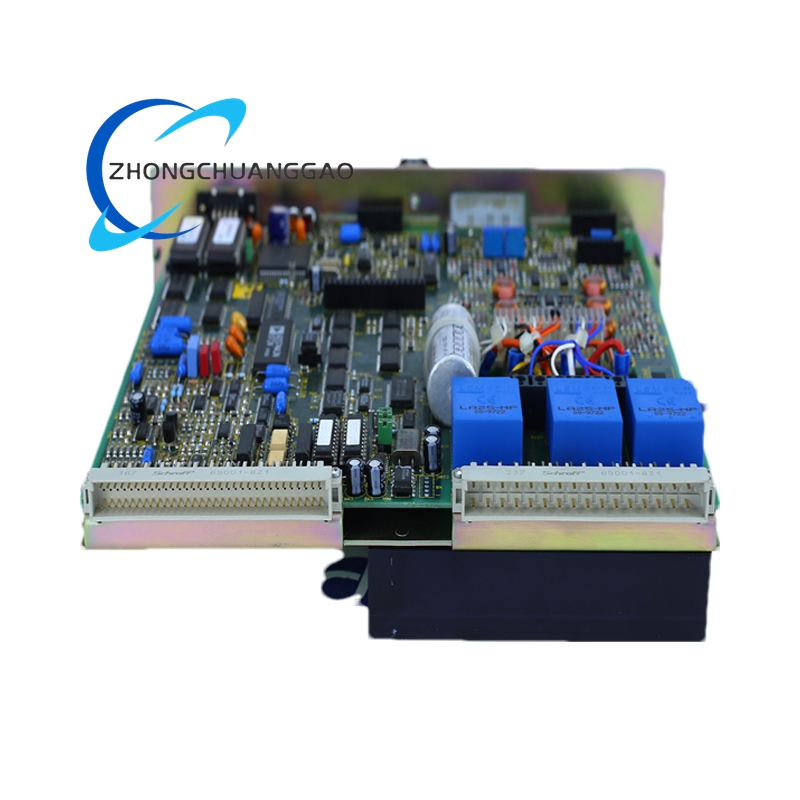

Moog D664-4747 L05HRBW6NET2-E Servo Proportional Valve

- Product Introduction: It is a product of the Moog D664 series servo proportional valves, which are pilot-operated proportional valves with integrated electronics and analog interfaces. The valve is designed for high-flow hydraulic control scenarios, with a two-stage or three-stage configuration. It has excellent dynamic performance and flow control accuracy, and can meet the control needs of large-scale hydraulic systems. The valve is widely used in various industrial fields due to its reliable performance and flexible configuration.

Detailed content

- Technical Specifications:

- Control Function: Flow control and pressure control.

- Mounting Standard: ISO 4401 Size 10 (NG 32).

- Hydraulic Parameters: The rated flow rate per land at a pressure difference of 5 bar (75 psi) is 1000-1500 l/min (264.1-396.2 gpm); the maximum flow rate can reach 3600 l/min (951 gpm); the maximum operating pressure of ports P, A, and B is 350 bar (5000 psi); the step response time for 0-100% step is 10-35 ms.

- Electrical Parameters: The supply voltage is 24 VDC (18-32 VDC); the rated signal options are ±10 V and ±10 mA; the electrical connector is 11+PE.

- Functional Features:

- The valve body is optimized for design, with a large flow passage area and low flow resistance.

- It can be configured as a two-stage or three-stage valve according to the dynamic performance requirements of the system.

- Optional ServoJet pilot valve, which has low pilot oil demand and stable performance.

- Equipped with multiple pressure and flow detection points, it is convenient for system monitoring and fault diagnosis.

- The sealing performance is excellent, and there is no leakage under high pressure.

- Application Scenarios: Suitable for large-scale industrial machinery, such as hydraulic systems of port cranes and bridge machines; in the field of energy, it is used for flow control of hydraulic systems in wind power generation and nuclear power equipment; in the metallurgical industry, it is applied to the hydraulic control system of steel rolling mills and blast furnaces to ensure stable operation of the equipment; it can also be used in the hydraulic system of ships and offshore platforms to withstand the harsh marine environment.