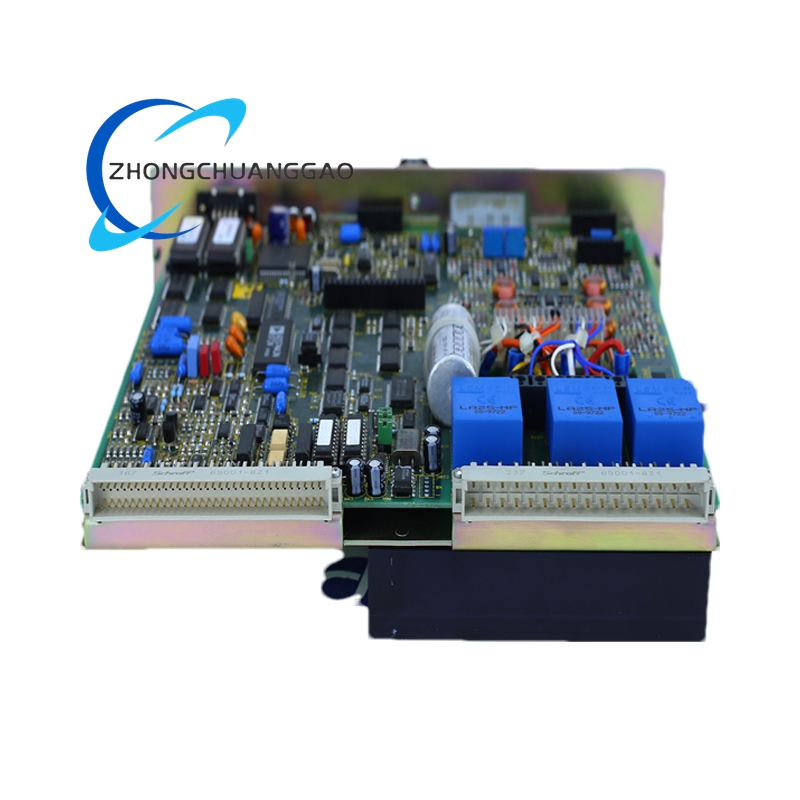

Moog D663-317K Servo Valve

- Product Introduction: This is a servo valve of the Moog D663 series, made of cast iron. It has the structural characteristics of a spool zero-notch and a spool valve body/spool valve sleeve assembly, and can realize valve functions such as Q, P, and PQ control. It is equipped with special nozzle sizes, coil assemblies, and torque motors, and can be selected according to actual operating pressure, valve size, and large flow requirements.

Detailed content

- Technical Specifications:

- Control Function: It can realize Q (flow), P (pressure), and PQ (flow-pressure) control.

- Structural Materials: The main body is made of cast iron.

- Hydraulic Data: The specific flow and pressure parameters need to be determined according to the actual configuration, but it is generally consistent with the performance level of the D663 series, with a high maximum operating pressure and a wide flow range.

- Electrical Data: It is equipped with corresponding coil assemblies and torque motors, and the electrical parameters such as the supply voltage and rated signal are matched with the overall design of the valve.

- Functional Features: It has explosion-proof models, including intrinsically safe flame-proof and “safer” designs, which can be used in hazardous environments. The spool and valve body structure ensures precise control, and the special nozzle and coil design improves the performance and adaptability of the valve.

- Application Scenarios: It is suitable for industrial fields that require high-precision control and may have explosion-proof requirements, such as the wall thickness control of blow molding equipment. It can be used with Moog’s DIGIPACK wall thickness controller to control the die opening of blow molding machines, applicable to both accumulator-type and continuous-type blow molding machines.