-

Technical Specifications:

-

Hydraulic Data: Rated flow ranges from 30 to 1,500 l/min (8 to 395 gpm) @ Δp 5 bar (75 psi) per land. Maximum flow can reach 3,600 l/min (950 gpm) for ISO size 10. Maximum operating pressure is 350 bar (5,000 psi). Mounting pattern complies with ISO 4401 sizes 05, 07, 08, and 10 (NG 10, 16, 25, and 32). 100% step response time is 10 to 50 ms @ 210 bar (3,000 psi).

-

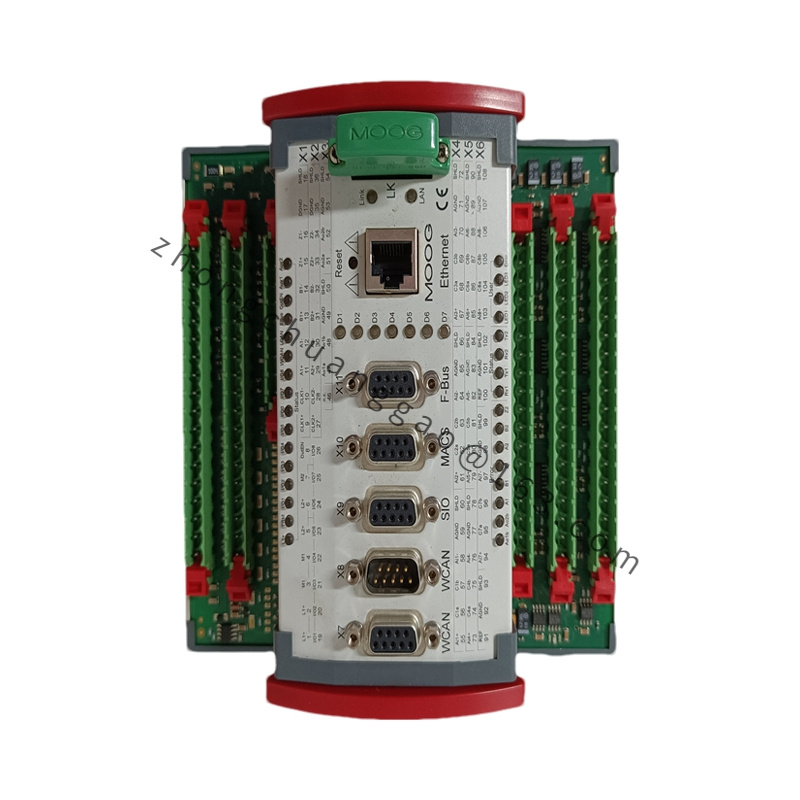

Electrical Data: Supply voltage is 24 VDC (18 to 32 VDC). Rated signal options include +/- 10 V, +/- 10 mA, and 4-20 mA. EMC performance meets the emission requirements of EN 55011:1998+A1:1999 (Class B) and the immunity requirements of EN 61000-4-3:2002-04+A1:2002-10.

-

Functional Features: It has excellent dynamic response due to the improved pilot stage. Optional servo nozzles or nozzle flapper pilot valves can be selected according to actual needs. Different fail-safe options are available to adapt to different application requirements and ensure the safety of the system in case of failure. It can accurately control the flow and pressure of the hydraulic system, realizing precise control of the actuators movement.

-

Application Scenarios: It is widely used in various industrial fields, such as plastic industry, metal forming, textile industry, power generation, and simulation. In the power plant steam turbine control field, it can be used to control the operation of steam turbines and gas turbines. It is also suitable for occasions that require high-precision control of hydraulic systems, such as the control of the electrode position of electric arc furnaces in steelmaking, the control of the tundish stopper rod and ladle level of continuous casting machines, and the vibration control of continuous casting machine crystallizers in the metallurgical industry.