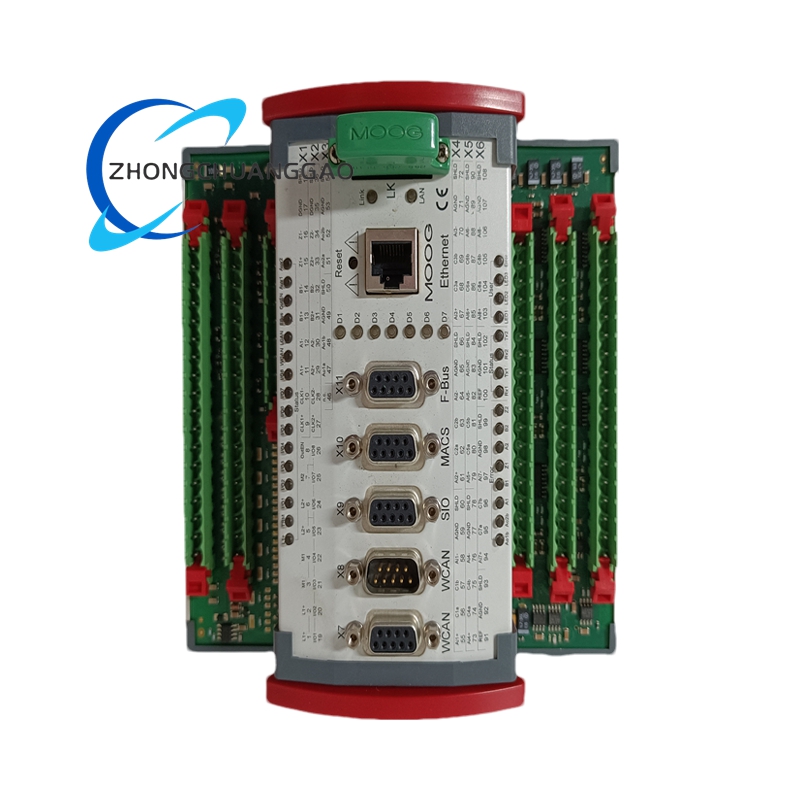

Moog D661Z2712G High-response Servo Valve

- Product Introduction: It is a high-response servo valve in Moog’s D661 series. It is improved on the basis of the basic model, with a more optimized pilot stage and main stage structure design, which greatly improves the dynamic response performance and control accuracy of the valve. The valve integrates advanced electronic control circuits and sensor components, which can realize real-time monitoring and closed-loop control of the spool position.

Detailed content

- Technical Specifications: The maximum operating pressure is 350 bar (5,000 psi); the rated flow range is 20 to 200 l/min (5.3 to 53 gpm) when the pressure drop per land is 35 bar (500 psi); the maximum flow can reach 250 l/min (65 gpm) (when the second T-port is connected); the 100% step response time is 6.5 to 14 ms under 210 bar (3,000 psi); the supply voltage is 24 VDC (18 to 32 VDC); the spool overlap is <±1%; the frequency response bandwidth can reach 150 Hz; the working temperature range is -40℃ to +120℃; the anti-pollution level is NAS 6 (with built-in filter).

- Functional Features: It adopts an improved Servo Jet pilot stage design, which has excellent dynamic response performance and can quickly convert electrical signals into hydraulic control signals; the main stage spool adopts a high-precision matching structure, with small spool overlap and high control precision; the integrated spool position detection sensor can realize real-time feedback of the spool position, and the closed-loop control circuit ensures the stability and accuracy of the spool position; it has multiple fail-safe options, which can make the spool move to a predetermined safe position when the power supply fails, ensuring the safety of the system; it has low hysteresis and high resolution, which can realize precise control of small flows.

- Application Scenarios: It is suitable for the precision control system of test equipment, such as the displacement control and load simulation of material fatigue test machines; it is used in the hydraulic control system of aerospace vehicles, such as the attitude control of small satellites and the thrust regulation of rocket engines; it is also applied in the control system of high-precision industrial robots, such as the position control of the robot’s end effector and the force control of the assembly process.