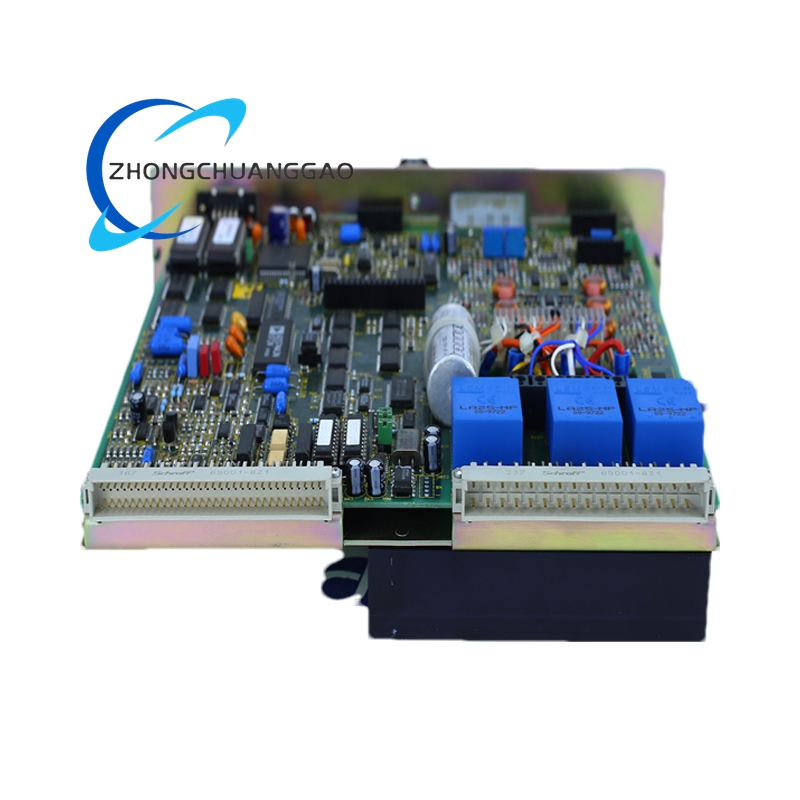

Moog D661-4697C G15JOAA5VSX2HA Pilot-Operated Servo Valve

- Product Introduction: This is a throttling type flow control valve belonging to the Moog D661 series. It has an integrated control circuit using SMD (Surface Mount Technology) and is powered by 24 VDC. It can convert electrical signals into hydraulic signals in the electro-hydraulic servo system, and then control the flow of the hydraulic system. It has the characteristics of high control precision and fast response, and can meet the needs of various industrial control scenarios.

Detailed content

- Technical Specifications:

- Hydraulic Parameters: The rated flow rate is 20 to 200 l/min (5.3 to 52.8 gpm) per land when the pressure difference is 35 bar (500 psi). The maximum flow rate is 250 l/min. The maximum operating pressure of ports P, A, and B is 350 bar (5000 psi). The maximum operating pressure of port T with internal Y is 210 bar (3000 psi), and the maximum operating pressure of port T with external Y is 350 bar (5000 psi). The step response time for 0 to 100% step is 6.5 to 18 ms. The installation pattern complies with ISO 4401 size 05 (NG 10).

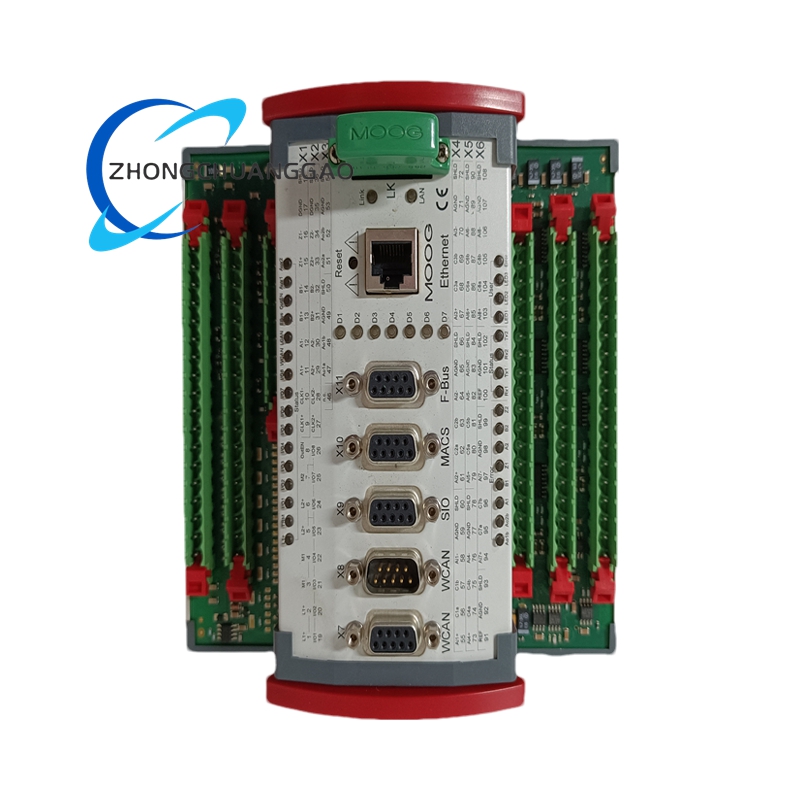

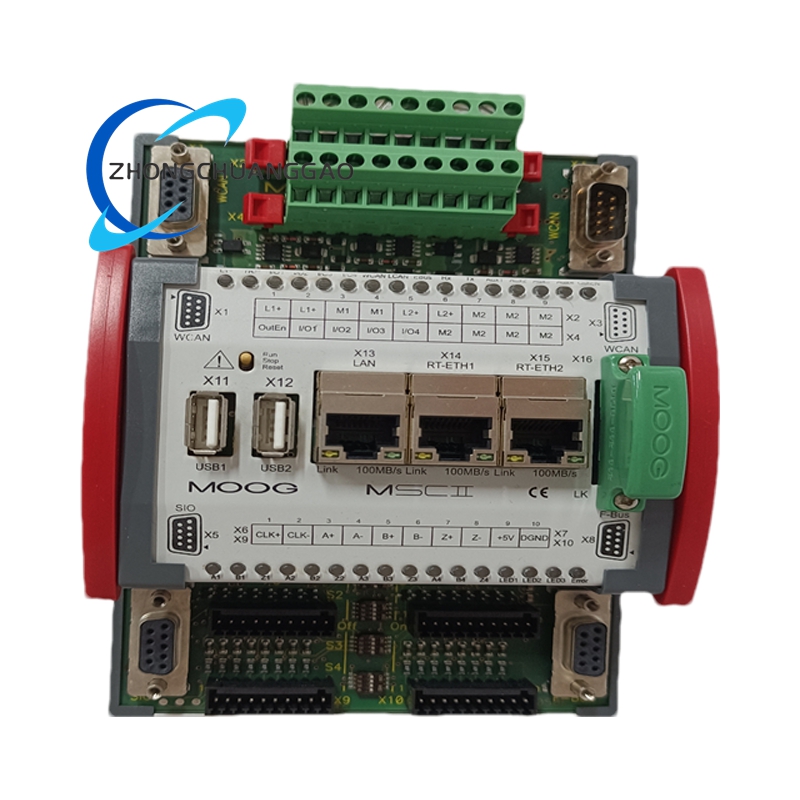

- Electrical Parameters: The supply voltage is 24 VDC (18 to 32 VDC), and the rated signal options are +/-10 V and +/-10 mA. The electrical connector is 6 + PE.

- Functional Features: It is a two-stage valve with a robust ServoJet pilot valve. The valve body is optimally designed to achieve a high rated flow rate. The improved ServoJet pilot valve design results in excellent dynamic response. The internal closed-loop control jet tube pilot stage ensures that the main valve spool can quickly and accurately respond to control signals, realizing high-precision flow regulation. Different fail-safe options are available to better adapt to the application.

- Application Scenarios: It is especially suitable for electro-hydraulic control systems with extremely high dynamic response requirements, such as position control, speed control, pressure control, and force control systems in the fields of machine tools, aerospace, and military equipment. It can also be used in general industrial automation fields that require precise flow control.