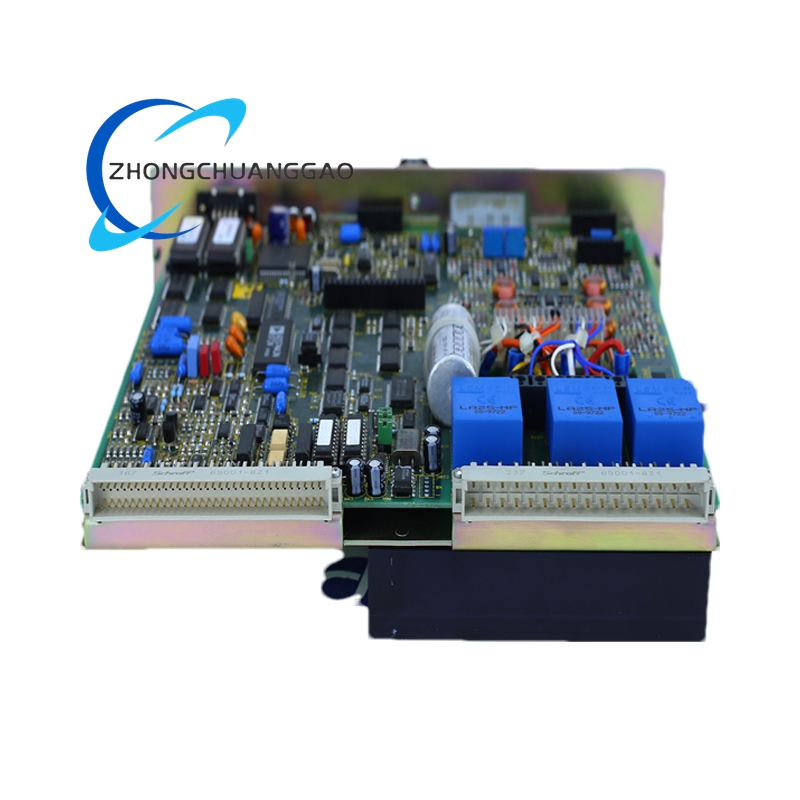

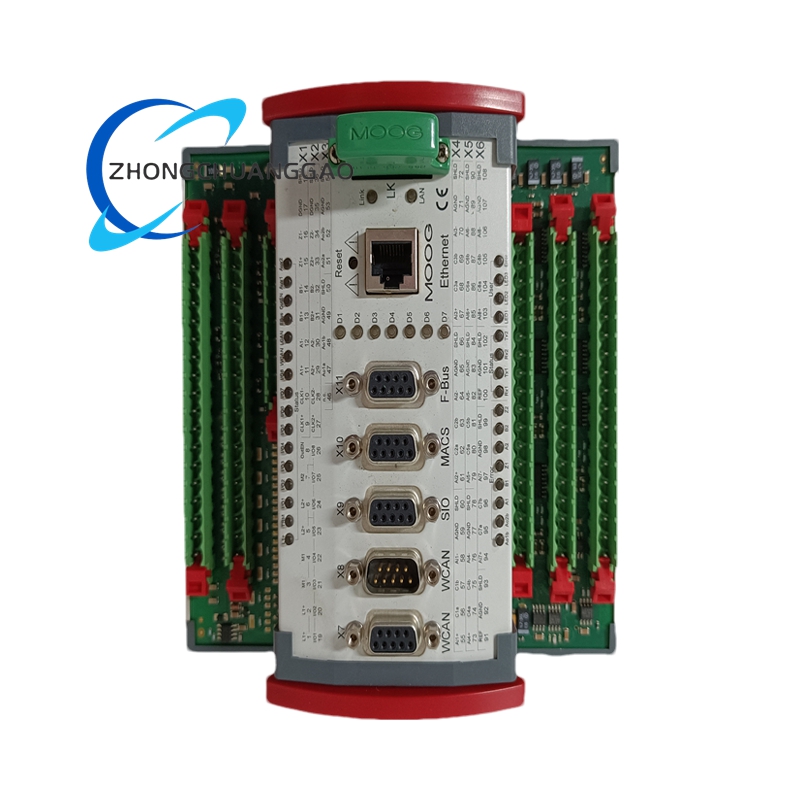

Moog D661-4640 Servo and Proportional Control Valve

- Product Introduction: It belongs to Moog’s D661 series of servo and proportional control valves with integrated electronics. It is a throttle valve suitable for two-way, three-way, and four-way applications, and can also be used for five-way applications when used as a proportional flow control valve. The valve is mainly used in electro-hydraulic position, speed, pressure, or force control systems that require high dynamic response, and can convert electrical signals into precise hydraulic control signals to achieve precise control of the system.

Detailed content

- Technical Specifications: The installation mode conforms to ISO 4401 size 05; the rated flow is 20 to 200 l/min (5.3 to 53 gpm) when the pressure drop per land is 35 bar (500 psi); the maximum flow can reach 250 l/min (65 gpm) (when the second T-port is connected); the maximum operating pressure is 350 bar (5,000 psi); the supply voltage is 24 VDC (18 to 32 VDC); the 100% step response time is 6.5 to 14 ms under 210 bar (3,000 psi).

- Functional Features: It adopts a nozzle-flapper or Servo Jet pilot stage, and the main stage spool is installed in the bushing. Some models are equipped with additional mechanical feedback devices to improve control accuracy and stability; the series has multiple sub-models, such as the G series without additional mechanical feedback, the S series with additional mechanical feedback, and the H series with improved performance (high response), which can meet different application requirements; the proportional flow control valve type can realize proportional control of flow, and has the characteristics of high linearity and repeatability; the integrated electronic components can provide stable driving signals for the valve, ensuring the consistency and reliability of the valve’s performance.

- Application Scenarios: It is widely used in the metal processing industry, such as the servo feed system of CNC machine tools, which controls the movement of the tool holder or workbench to ensure processing accuracy; it is used in the automotive manufacturing industry, such as the control of the hydraulic system of stamping equipment and the position control of the robot’s welding arm; it is also applied in the aerospace field, such as the control of the hydraulic system of aircraft ground test equipment and the load simulation of engine test benches.