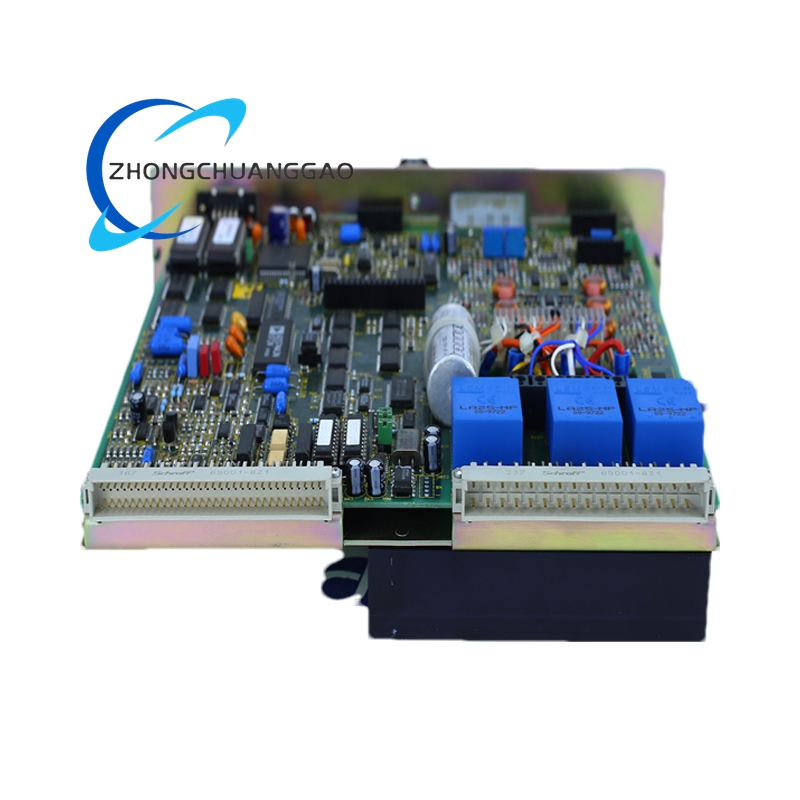

Moog D661-4203 Pilot-Operated Servo Valve

- Product Introduction: As part of the Moog D661 series, it is a pilot-operated servo valve with integrated electronics and analog interfaces. The spool of the valve slides in the sleeve and is controlled by hydraulic pilot operation. The design ensures high precision, excellent static and dynamic performance, and is suitable for the most demanding application scenarios, providing high dynamic performance to meet the precise control needs of hydraulic systems.

Detailed content

- Technical Specifications:

- Control Function: Flow control.

- Mounting Standard: ISO 4401 Size 05 (NG 10).

- Hydraulic Parameters: The rated flow rate per land at a pressure difference of 35 bar (500 psi) is 20-200 l/min (5.3-52.8 gpm); the maximum flow rate is 250 l/min; the maximum operating pressure of ports P, A, and B is 350 bar (5000 psi); the maximum pressure of port T with internal Y is 210 bar (3000 psi), and with external Y is 350 bar (5000 psi); the step response time for 0-100% step is 6.5-18 ms.

- Electrical Parameters: The supply voltage is 24 VDC (18-32 VDC); the rated signal options are ±10 V and ±10 mA; the electrical connector is 6+PE.

- Functional Features:

- It is a two-stage valve with a robust ServoJet pilot valve, ensuring stable and reliable operation.

- The valve body is optimally designed to achieve high rated flow.

- The improved ServoJet pilot valve design significantly improves dynamic response.

- Multiple fail-safe options are available to choose the most suitable configuration according to application requirements.

- Equipped with a high-precision spool and sleeve, it ensures precise flow control and efficient operation.

- The integrated control amplifier simplifies system integration and reduces external wiring.

- Application Scenarios: Widely used in electro-hydraulic position, speed, pressure, or force control systems requiring high dynamic response, such as aerospace hydraulic control systems, ensuring precise control of aircraft components; in the field of mechanical manufacturing, used in CNC machine tools and automated production lines to improve processing accuracy and production efficiency; also applicable to test systems, such as material performance testing machines and structural fatigue testing equipment, providing precise hydraulic drive control.