Moog D661-2304 Electro-Hydraulic Servo Valve

Technical Specifications:

- Nominal Flow Rate: 20 to 200 L/min (5.3 to 53 GPM) at ΔP = 5 bar (72.5 PSI)

- Maximum Operating Pressure: 350 bar (5,075 PSI)

- Input Signal: ±10 VDC or 4-20 mA (compatible with standard industrial controllers)

- Hysteresis: ≤0.5% (ensures minimal positional error)

- Linearity: ±1% (tight control over output)

- Frequency Response: Up to 100 Hz (-3 dB) for rapid adjustments

- Stage Design: Two-stage with servo-jet pilot stage and four-way main stage

- Mounting Interface: ISO 4401-05-05-0-94 standard for easy integration

- Weight: Approximately 3.5 kg (7.7 lbs)

Detailed content

Functional Features:

- High Dynamic Response: The servo-jet pilot stage enables fast valve core movement, reducing settling time to ≤25 ms for step inputs.

- Precision Control: Tight tolerance between valve core and sleeve (2-4 μm) minimizes leakage and ensures accurate flow regulation.

- Durability: Hardened alloy components resist wear, extending service life to over 1.2 million cycles.

- Environmental Adaptability: Operates in temperatures from -20°C to 70°C (-4°F to 158°F) and handles various hydraulic fluids (mineral oil, phosphate ester).

- Maintenance-Friendly: Modular design allows component replacement without disassembling the entire valve.

- Diagnostics: Optional fault monitoring for coil status and performance degradation.

Applications:

- Aerospace: Flight control actuators, engine test rigs, and wind tunnel simulations.

- Industrial Automation: Precision presses, CNC machine tool feed systems, and robotic arms.

- Energy: Turbine speed control in power plants and hydraulic systems for renewable energy.

- Material Processing: Die-casting machine speed control and composite material forming.

- Metallurgy: Roll gap adjustment in rolling mills and tension control in continuous casting lines.

Performance Advantages:

- Stability Under Pressure: Maintains consistent flow even at 210 bar (3,045 PSI) with ±0.5% control precision.

- Energy Efficiency: Low internal leakage (≤0.6 L/min at 35 bar) reduces power consumption.

- Vibration Resistance: Meets MIL-STD-883 standards for shock and vibration (30g, 3-axis).

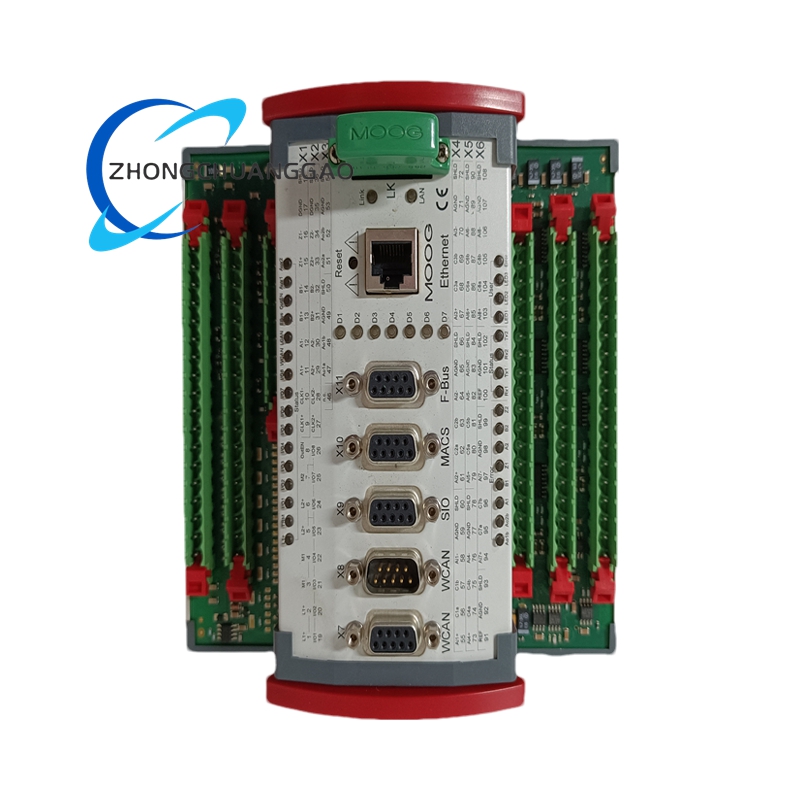

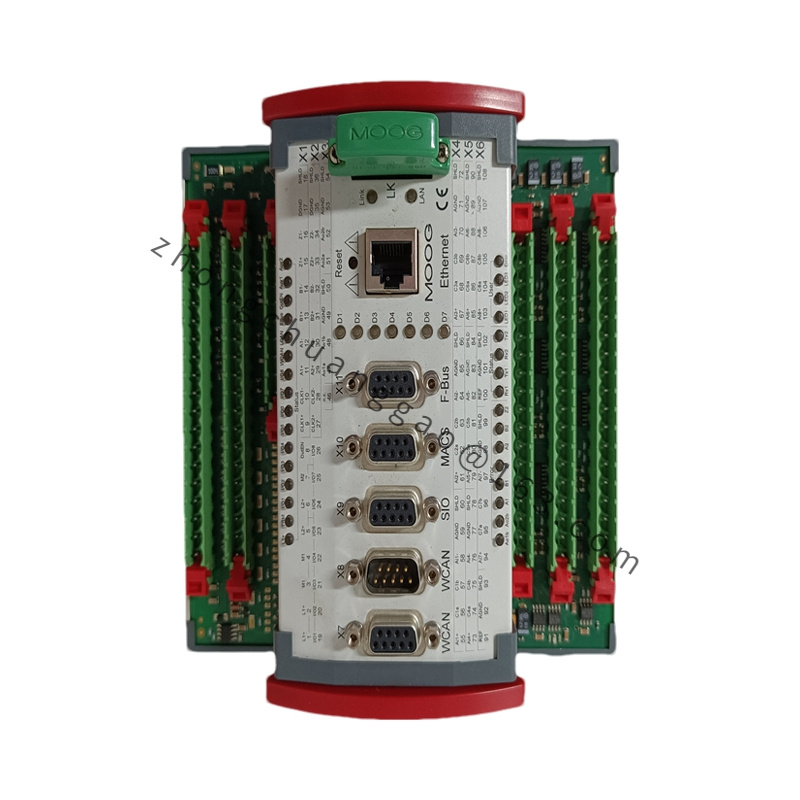

Integration Options:

- Electronic Amplifiers: Supports external or integrated amplifiers for closed-loop control.

- Signal Flexibility: Accepts ±10 VDC, 4-20 mA, or PWM inputs for compatibility with diverse controllers.

- Safety Features: Fail-safe design reverts to a neutral position during power loss.

Industry Certifications:

- Complies with ISO 9001 (quality management) and ATEX/IECEx (hazardous environment) standards.

Typical Use Cases:

- Hydraulic Presses: Controls ram speed with micron-level precision for metal forming.

- Wind Turbines: Adjusts pitch angle dynamically to optimize energy capture.

- Automotive Testing: Simulates driving loads in engine and chassis test benches.