Moog D634-1003 Direct-Acting Servo Valve

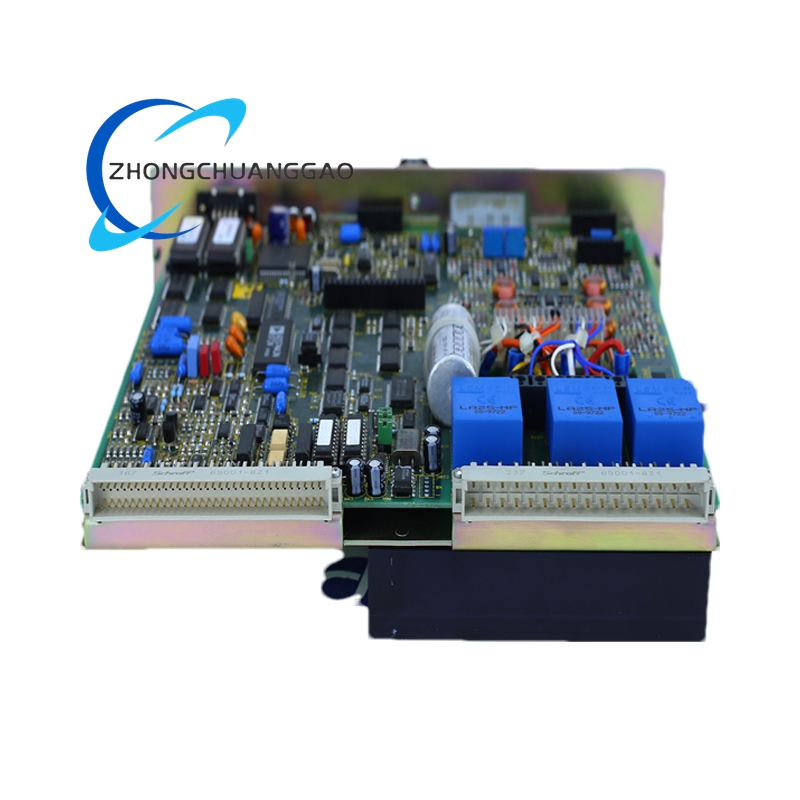

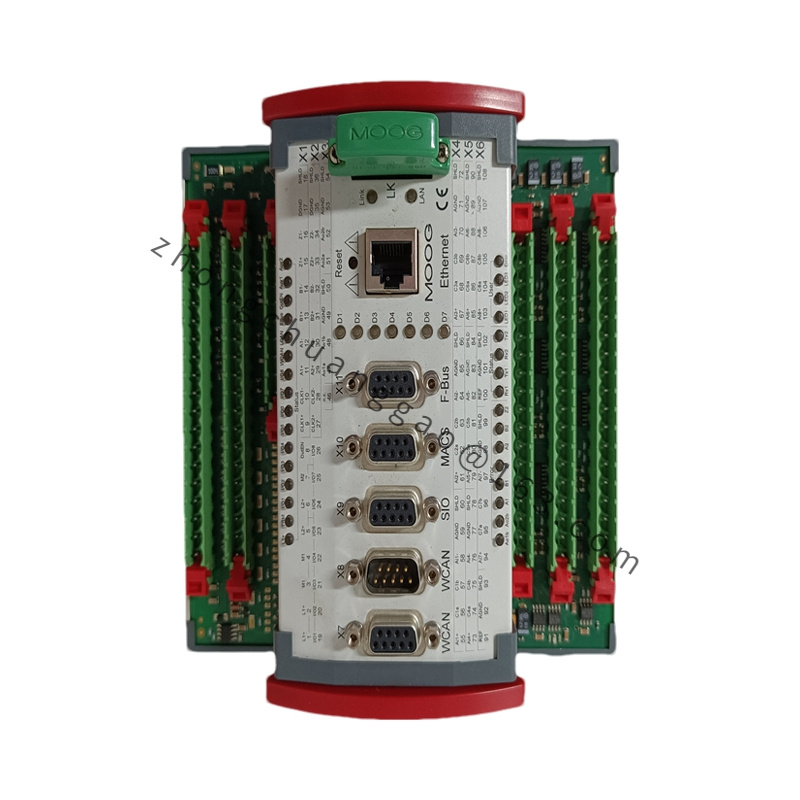

- Product Introduction: The D634-1003 is a direct-acting servo valve (DDV) with closed-loop position control of the live feedback valve core. It is a throttle-type flow control valve that can be applied to three-way, four-way and 2×2-way valves. The valve integrates a closed-loop valve position control circuit board and a pulse width modulation (PWM) drive circuit, with advanced design and reliable performance.

Detailed content

- Technical Specifications: The installation specification complies with ISO 4401-05-05-0-94 (with or without drain port). The valve port diameter is 11.5 mm (0.45 inches). It is a single-stage valve, sliding valve type with valve sleeve. The valve core is directly driven by a permanent magnet linear force motor, without a pilot stage. The weight is 6.3 kg (13.9 lbs). The rated flow rate at 35 bar (500 psi) pressure drop per throttling edge is 60/100 l/min (15.8/26.3 gpm) (±10%). The maximum flow rate of the valve is 185 l/min (48.8 gpm). The maximum working pressure of ports P, A, B is 350 bar (5000 psi); the maximum working pressure of port T (internal discharge) is 50 bar (715 psi); the maximum working pressure of port T (Y port drain) and valve port Y is 350 bar (5000 psi).

- Functional Characteristics: Driven by a permanent magnet linear force motor, it has high driving power and does not require a pilot oil source. The dynamic performance is not affected by pressure, with low hysteresis and high resolution. The power consumption is low at and near the hydraulic zero point. The standardized valve core position detection signal can be used to obtain the system operation status, which is very beneficial to the maintenance of the valve. It supports electrical zero adjustment. In case of power failure, cable damage or emergency stop, the valve core will automatically return to the spring centering position without external force.

- Application Scenarios: Suitable for electro-hydraulic position, velocity, pressure or force control systems and other systems requiring high dynamic response. It is widely used in industrial fields such as machine tools, plastic machinery, metallurgical equipment and aerospace test equipment. For example, in the control system of CNC machine tools, it is used to control the feed movement of the workbench to ensure processing precision; in the plastic injection molding machine, it controls the movement of the injection nozzle and mold clamping mechanism.