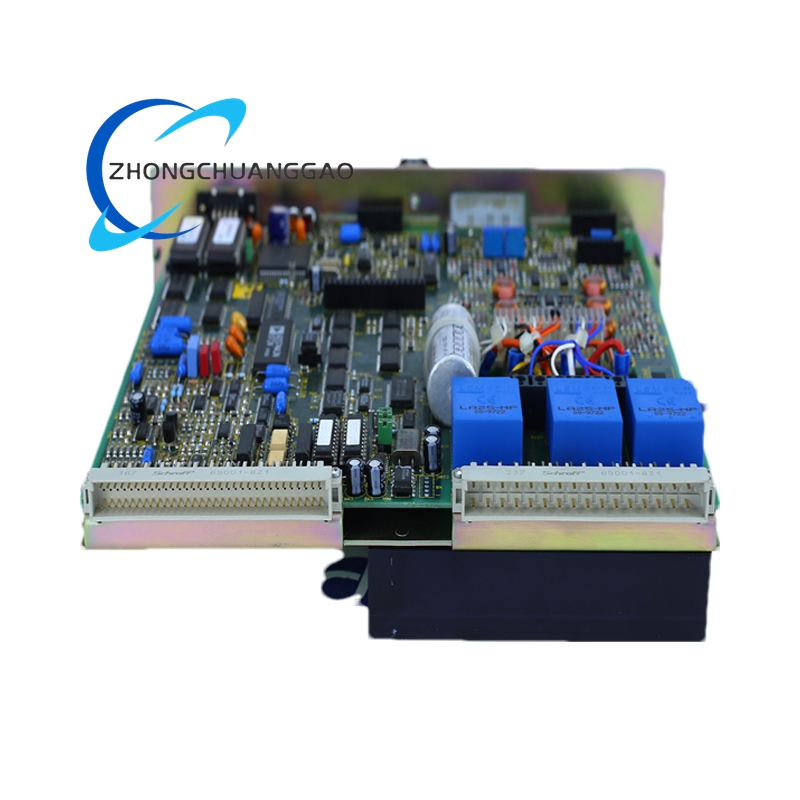

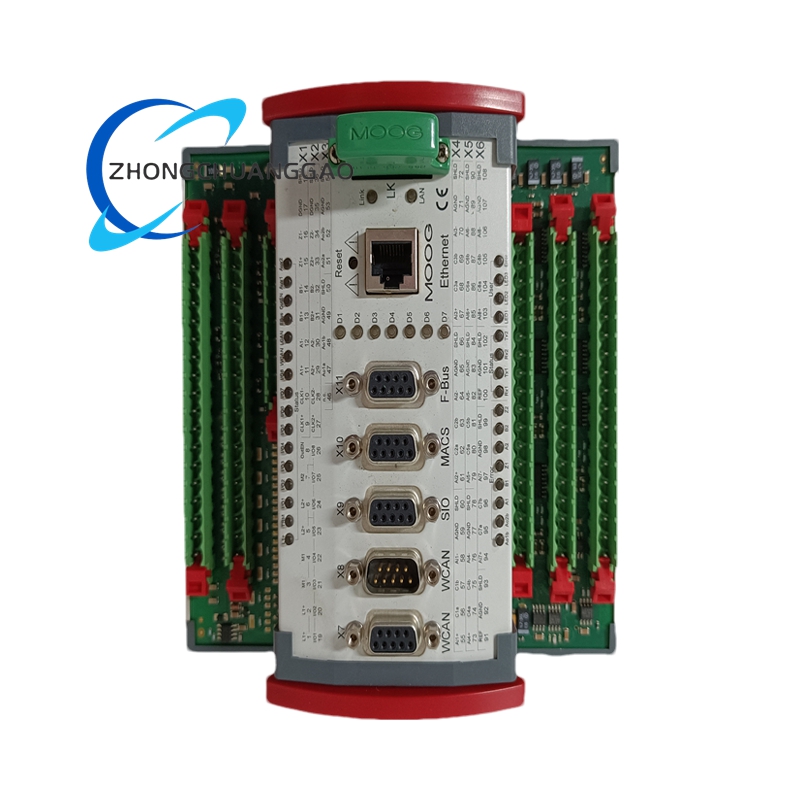

Moog D633-7398 Direct-Acting Servo Valve

- Product Introduction: As part of Moog’s D633 series, this direct-acting servo valve is designed with closed-loop position control of the valve core with real-time feedback. It is a throttle-type flow control valve suitable for multiple valve configurations, including three-way, four-way, and 2×2-way valves. It plays a crucial role in electro-hydraulic control systems by converting electrical signals into precise hydraulic flow control, meeting the requirements of high dynamic response in various industrial applications.

Detailed content

- Technical Specifications: The maximum working pressure for ports P, A, and B is 350 bar (5075 psi). The rated flow ranges from 5 to 40 L/min (1.3 to 10.6 gpm) when the pressure difference across the throttling edge is 35 bar, and the maximum flow capacity of the valve is 75 L/min (19.8 gpm). The valve port has a diameter of 7.9 mm (0.31 inches). The installation conforms to the ISO 4401-03-03-0-94 standard. The valve weighs 2.5 kg (5.5 lb). It operates within a temperature range of -40℃ to +120℃, and the recommended viscosity of the hydraulic oil is between 10 and 97 mm²/s (cst).

- Functional Features: Driven by a permanent magnet linear force motor, it provides high driving power, enabling bidirectional movement of the valve core from the spring-centered position, which is a significant advantage over traditional proportional solenoid valves with only one-way driving force. The integrated closed-loop control circuit board and PWM drive technology ensure linearity between the input current and valve core displacement, resulting in low hysteresis and high resolution for precise flow control. It eliminates the need for an external pilot oil supply, and its dynamic performance remains unaffected by pressure changes. In the event of power failure, cable damage, or emergency stop, the valve core automatically returns to the spring-centered position without external force, enhancing operational safety. The robust construction using high-strength materials ensures excellent wear resistance and a long service life.

- Application Scenarios: It is extensively used in metal forming equipment like shears, bending machines, and pipe benders, as well as wood presses. It is also ideal for hydraulic test benches, metallurgical machinery, and other industrial systems that demand high dynamic response and accurate flow control.