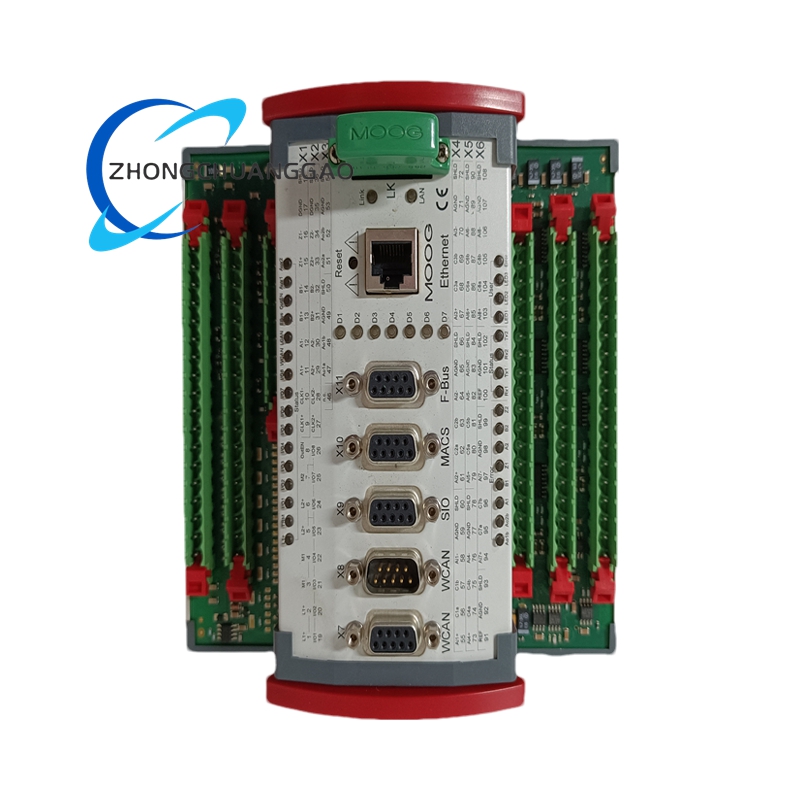

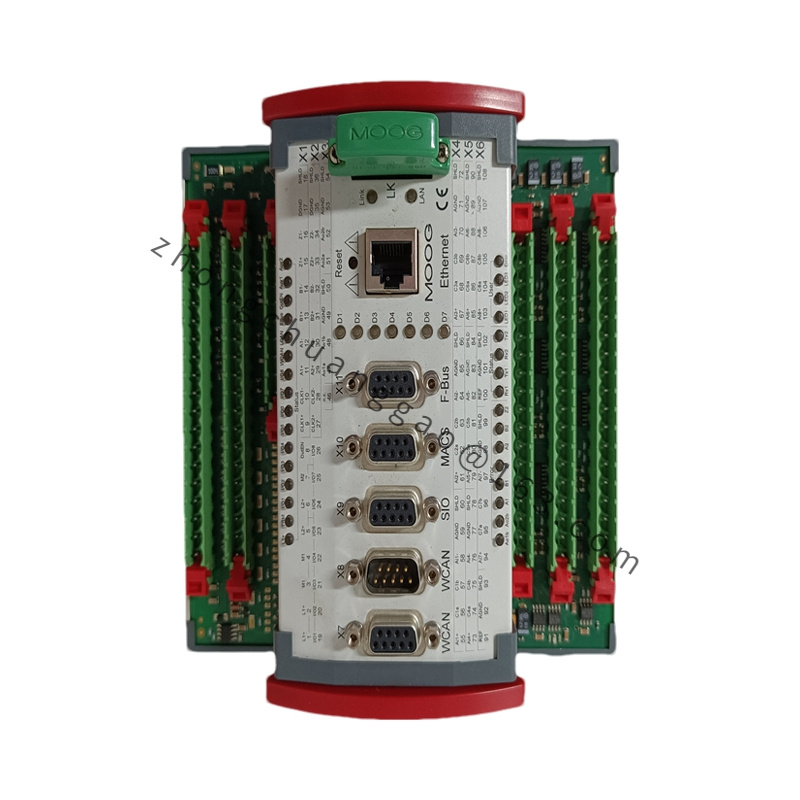

Moog D633-7333Direct-Acting Servo Valve

- Product Introduction: It is a member of Moog’s D633 series. It is a throttle-type flow control valve with closed-loop position control of the spool with live feedback. The valve core is driven by a permanent magnet linear force motor, which can flexibly drive the valve core to move in two directions from the spring-centered position. The valve integrates a closed-loop valve position control circuit board and a pulse width modulation (PWM) drive circuit, representing a significant development characterized by SMD technology.

Detailed content

- Technical Specifications: It is a single-stage valve, a slide valve type with a valve sleeve, which can be three-way, four-way, or 2*2 way. The driving mode is the direct drive of the permanent magnet linear force motor, without a pilot stage. The weight is 6.3kg. The maximum working pressure of ports P, A, and B is 350bar (5000psi). The maximum working pressure of port T (internal discharge) is 50bar (715psi). The maximum working pressure of port T (Y port drain) is 350bar (5000psi). The response time (spool 0-100% full opening) is ≤20ms. The resolution is less than 0.1%. The hysteresis is less than 0.2%. The zero drift (△t=55k) is less than 1.5%. The maximum zero leakage (zero opening) is 1.2/2.0 l/min (0.26/0.53 gpm).

- Functional Features: It is directly driven by a permanent magnet linear force motor with high driving power. No pilot oil source is required. The dynamic performance is not affected by pressure. It has low hysteresis and high resolution. The power consumption is low at and near the hydraulic zero point. The standardized spool position detection signal can be used to obtain the operation status of the system, which is very beneficial for valve maintenance. It supports electrical zero adjustment.

- Application Scenarios: It is suitable for electro-hydraulic position, speed, pressure, or force control systems and other systems that require high dynamic response. It is widely used in industrial automation, aerospace, and other fields. For example, in the flight simulation system of aerospace equipment, it controls the movement of the simulator to achieve a realistic simulation effect. In the automated production line of industrial automation, it controls the movement of the manipulator to improve production efficiency and accuracy.