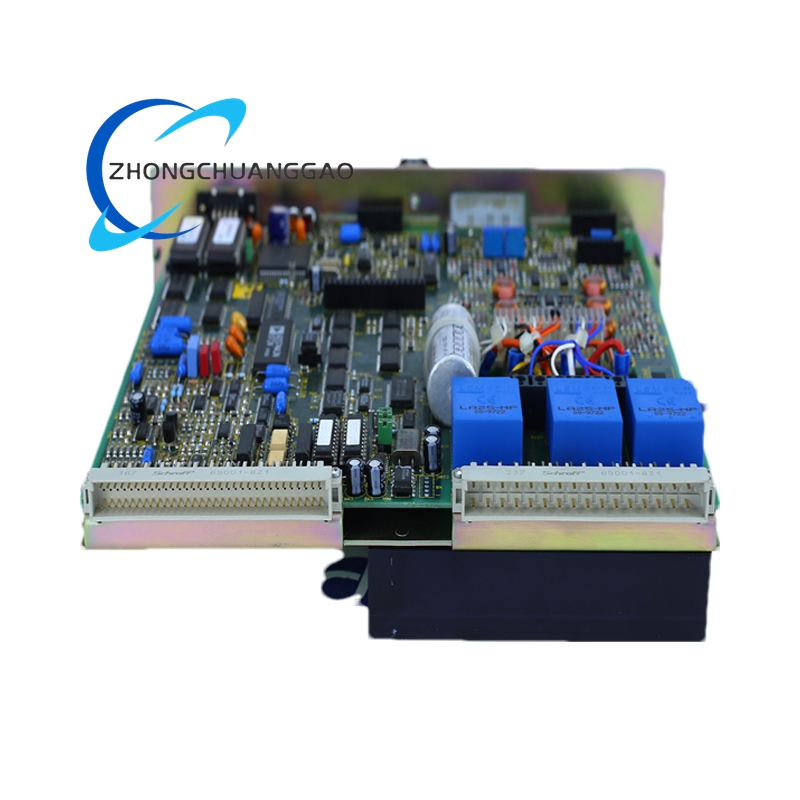

Moog D633-518BDirect-Acting Servo Valve

- Product Introduction: It belongs to Moog’s D633 series of direct-acting servo valves, which are high-performance electro-hydraulic control components. The valve adopts a closed-loop position control mode of the valve core with real-time feedback. It is a throttle-type flow control valve that can be applied to three-way, four-way, and 2×2-way valve systems. It is mainly used to convert weak electrical signals into high-precision hydraulic output, so as to realize the precise control of electro-hydraulic position, speed, pressure, or force.

Detailed content

- Technical Specifications: The maximum working pressure of ports P, A, and B is 350 bar (5075 psi). When the pressure difference at the throttling edge is 35 bar, the rated flow range is 5 – 40 L/min (1.3 – 10.6 gpm), and the maximum flow of the valve can reach 75 L/min (19.8 gpm). The valve port diameter is 7.9 mm (0.31 inches). The installation specification complies with ISO 4401-03-03-0-94. The weight of the valve is 2.5 kg (5.5 lb). The working temperature range is -40℃ to +120℃, and the recommended viscosity range of the hydraulic oil is 10 to 97 mm²/s (cst).

- Functional Features: The valve core is directly driven by a permanent magnet linear force motor, which has high driving power and can flexibly drive the valve core to move in two directions from the spring-centered position, overcoming the limitation that traditional proportional solenoid valves can only provide one-way driving force. It integrates a closed-loop valve core position control circuit board and pulse width modulation (PWM) drive technology to ensure a linear relationship between the valve core displacement and the input current. It has low hysteresis and high resolution, and the minimum controllable flow is small, ensuring precise control. It does not require an external pilot oil source, and its dynamic performance is not affected by pressure. When power is off, the valve core can automatically return to the spring-centered position without external force, ensuring safe operation. The valve body is made of high-strength materials, which has good wear resistance and long service life.

- Application Scenarios: It is widely used in metal forming equipment such as shears, bending machines, and pipe bending machines, as well as wood presses. It is also applicable to hydraulic test benches, metallurgical machinery, and other fields that require high dynamic response and precise control.