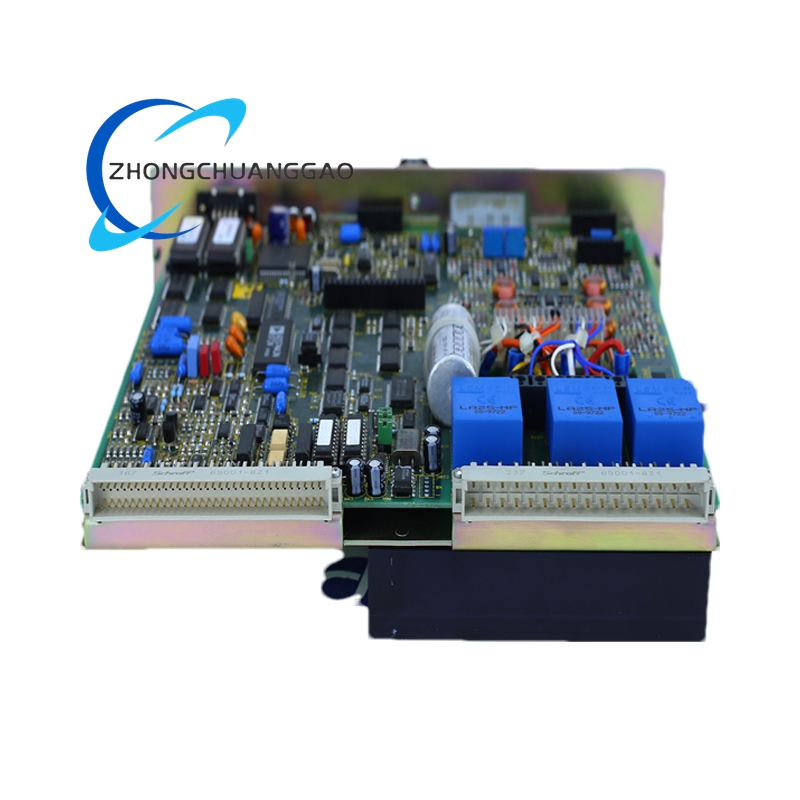

Moog D633-313B Series Direct Drive Analog Control Servo Valve

- Product Introduction: This is a direct-drive analog control servo valve of Moog. The D633 and D634 series are direct-drive valves with electric closed-loop spool position control. It is a throttle type flow control valve suitable for 3-way and ideal 4-way applications. Its high-performance two-stage design has a rated flow rate of 3.8 l/min to 227 l/min when the valve pressure drop is 35 bar. The output stage of the valve is a closed-center 4-way spool valve, and the pilot stage is a double-nozzle flapper valve. The design is simple and durable, and can provide reliable and long-term stable operation.

Detailed content

- Technical Specifications: The manufacturer is Moog. The type is direct-drive analog control servo valve. The valve design is 1-stage, with spool and bushing. The size is 3. The ambient temperature range is -20°C to 60°C. The maximum operating pressure of ports P, A, and B is 350 bar. The maximum operating pressure of port T without Y is 50 bar. The maximum operating pressure of port T with Y is 350 bar. The maximum flow rate is 75 l/min. The temperature range is -20°C to 80°C. The step response time for 0 to 100% stroke is ≤ 12 ms. The supply voltage is 24V DC. The signal is ±10V.

- Functional Features: It is directly driven by a permanent magnet linear force motor, which provides high driving force and can work in two directions. The direct-drive design does not require pilot oil, avoiding leakage loss of the pilot stage. The dynamic response is independent of pressure, and the control performance is stable. It has low hysteresis and high response characteristics, enabling the system to have excellent repeatability. The power demand is low at and around the spool center position, resulting in lower energy consumption during most operating and standby times. When the power supply fails, the cable is broken, or the emergency stop is activated, the spool returns to the preset spring-centered position without passing through the fully open control port position, improving safety.

- Application Scenarios: It is widely used in the field of industrial machinery, such as the control system of injection molding machines, extruders, and forging machines, to realize precise control of the movement of mechanical parts. It is applied in the field of aerospace, such as the hydraulic control system of aircraft and spacecraft, to ensure the stable operation of the aircraft’s flight control system and landing gear. In the field of energy, it can be used in the hydraulic control system of wind power generators and hydropower units to improve the efficiency and stability of energy conversion. In addition, it is also used in the field of test equipment, such as material testing machines and fatigue testing machines, to ensure the accuracy of test data.