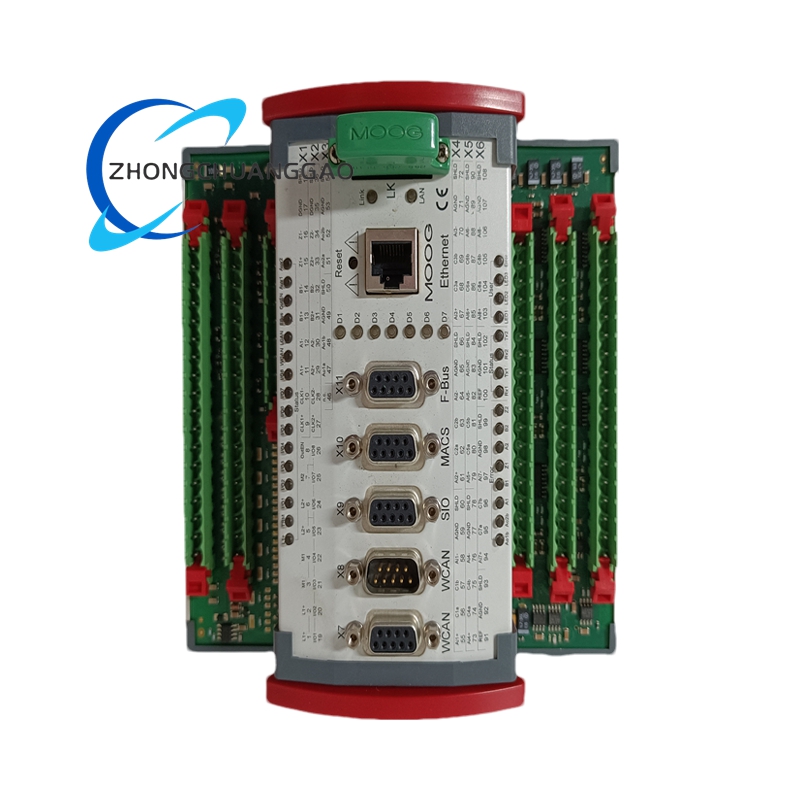

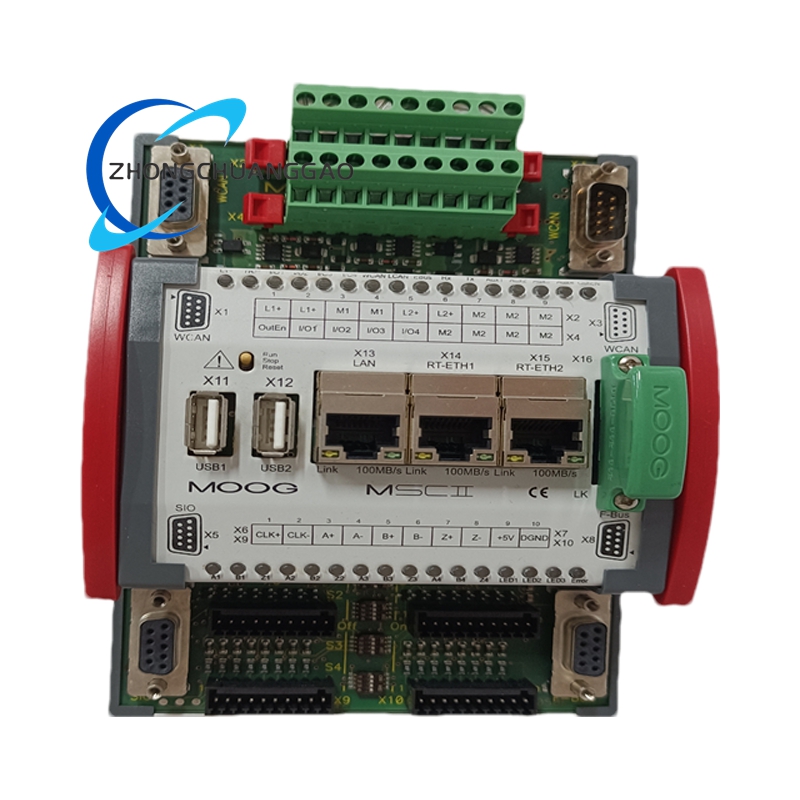

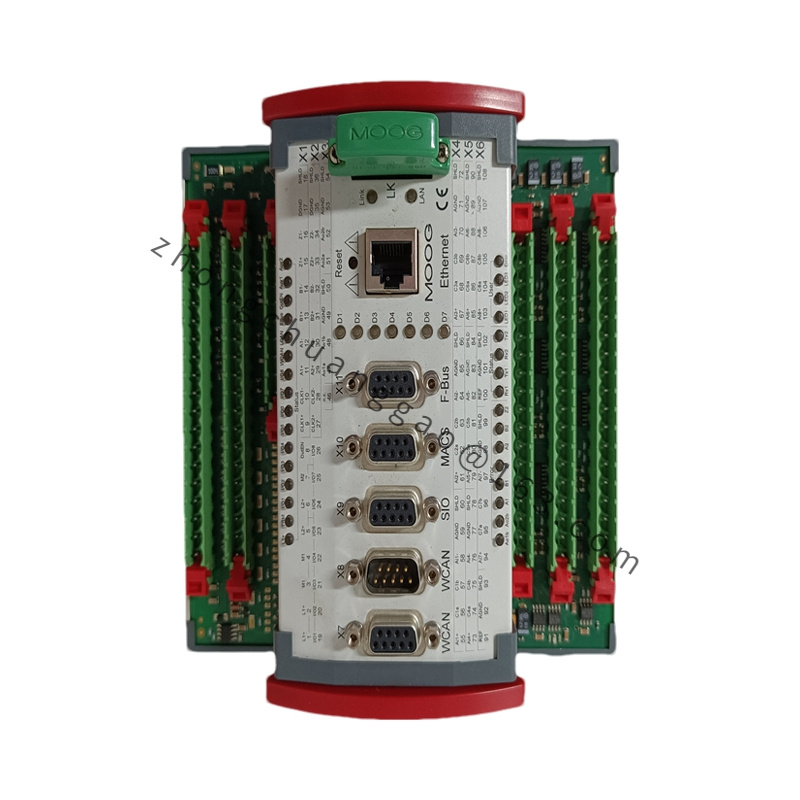

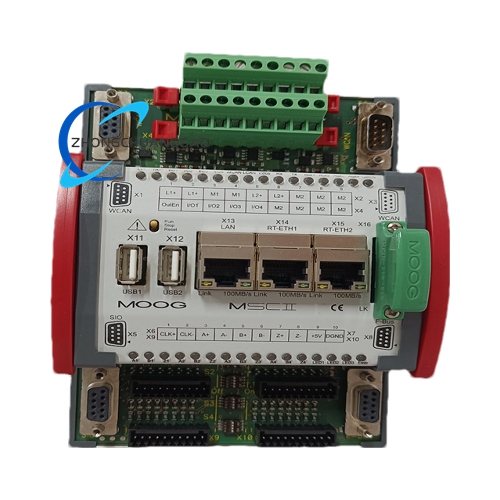

MOOG D136-002-005 Multi-Axis Motion Controller

Technical Specifications

- Control Axes: Supports 1-8 axes (configurable based on application requirements) .

- Control Types:

- Position control

- Velocity control

- Force/pressure control .

- Feedback Interfaces:

- Incremental encoders

- Absolute encoders

- Analog sensors (e.g., displacement, pressure sensors) .

Detailed content

- Communication Protocols:

- EtherCAT, CANopen

- Analog/digital I/O

- Optional Profibus-DP slave interface (up to 12 Mbit) .

- Programming Language: Compliant with IEC 61131-3 standard .

- Power Supply: 24 V DC ±10% .

- Operating Temperature: 0°C to +50°C .

- Protection Rating: IP20 (standard); higher ratings (e.g., IP67) available for harsh environments .

- Dongle Requirement: Requires D138-002-002 hardware dongle for software activation and full functionality .

Functional Features

- High-Precision Control:

- Achieves micron-level positioning accuracy with minimal steady-state error, ideal for precision machining and testing equipment .

- Rapid Dynamic Response:

- Advanced control algorithms (e.g., PID tuning) enable high-speed motion stability; servo jet pilot valve technology delivers 500 Hz undamped natural frequency .

- Flexible Control Modes:

- Seamless switching between position, velocity, and force control modes .

- Fault-Safe Design:

- Integrated centering springs reset valve spools to neutral during power loss or system failure, preventing uncontrolled movements .

- Energy Efficiency:

- Utilizes >90% of pilot-stage flow, reducing energy consumption (especially in multi-valve systems) .

- Robust Contamination Resistance:

- Built-in 200 µm nominal clearance filter ensures near-infinite operational life in industrial environments .

- Built-in 200 µm nominal clearance filter ensures near-infinite operational life in industrial environments .

Application Scenarios

- Precision Machinery:

- CNC machine tool trajectory control, injection molding machine mold movements .

- Industrial Automation:

- Robotic arm coordination, packaging line synchronization, high-accuracy printing machinery .

- Testing Equipment:

- Fatigue testers for load simulation, material testing rigs .

- Aerospace:

- Flight simulator actuation, hydraulic actuator validation platforms .

- Medical Devices:

- CT scanner positioning systems, surgical robot motion control .

Compatible Products & Ecosystem

- Key Accessories:

- MOOG Servo Valves (e.g., D661–D665 series) for hydraulic actuation .

- MOOG Servo Motors/Drives (e.g., G-series) for electric actuation .

- Software Tools:

- Moog Application Software Suite (MASS): CODESYS-based IEC 61131-3 development environment for programming and diagnostics .

- Expansion Modules:

- Analog I/O modules (e.g., QAI016/4) for enhanced signal processing .

Installation & Maintenance Guidelines

- Installation Requirements:

- Avoid vibration-prone locations; ensure ambient temperature/humidity aligns with specifications .

- Dongle Handling:

- Connect D138-002-002 dongle to USB port before controller initialization .

- Preventive Maintenance:

- Bi-annual inspections: Verify cable integrity, clean cooling vents, test redundant module switching .

- Troubleshooting:

- Sudden pressure drops in hydraulic systems may indicate cavitation; verify liquid oxygen pump parameters .

Certifications & Support

- Warranty: 12-month manufacturer warranty .

- Global Service: Technical support via MOOG engineers; expedited shipping (e.g., SF Express/DHL) .