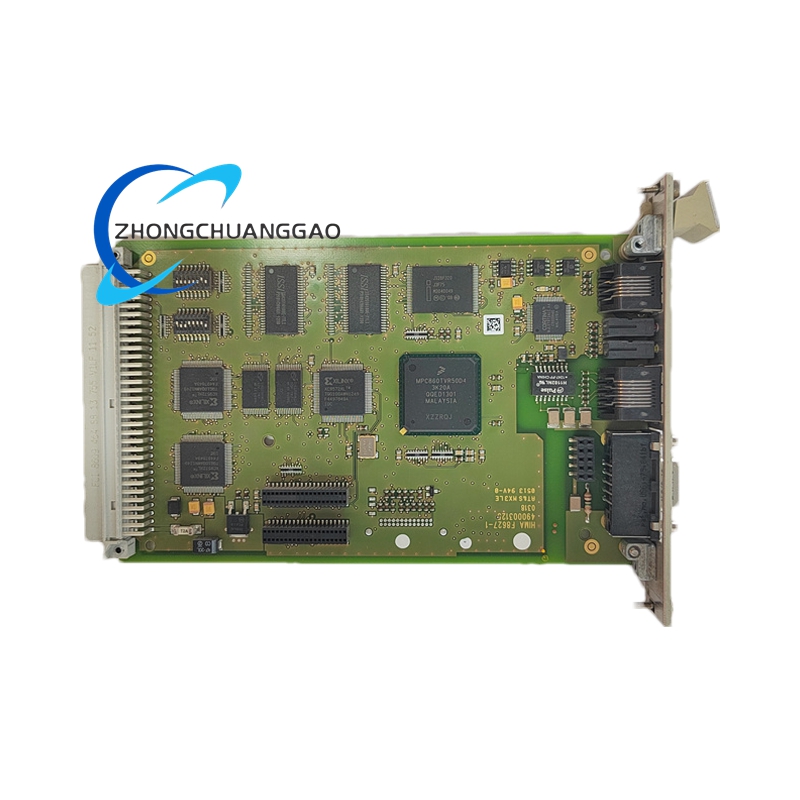

Hima L17089FF1

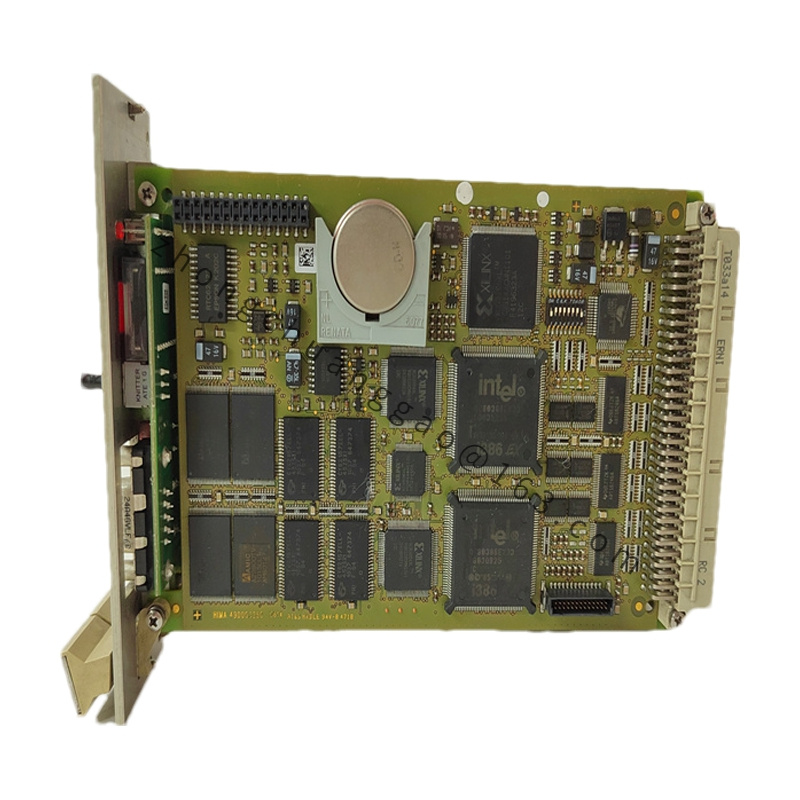

- Product Introduction: The Hima L17089FF1 is a specialized module designed for integration into Hima’s safety instrumented systems (SIS), focusing on reliable data transmission and interface compatibility with other system components. It is engineered to meet strict industrial safety standards, ensuring seamless and secure communication between different parts of a safety-critical setup, which is essential for maintaining operational integrity in high-risk environments.

Detailed content

- Technical Specifications:

- Communication Protocol: Supports industry-standard protocols optimized for safety-related data exchange, ensuring low latency and high data integrity.

- Operating Voltage: Typically operates within a range of 24V DC (±10% tolerance) to align with common industrial power systems.

- Operating Temperature: Rated for -20°C to +60°C, enabling stable performance in harsh industrial climates with temperature fluctuations.

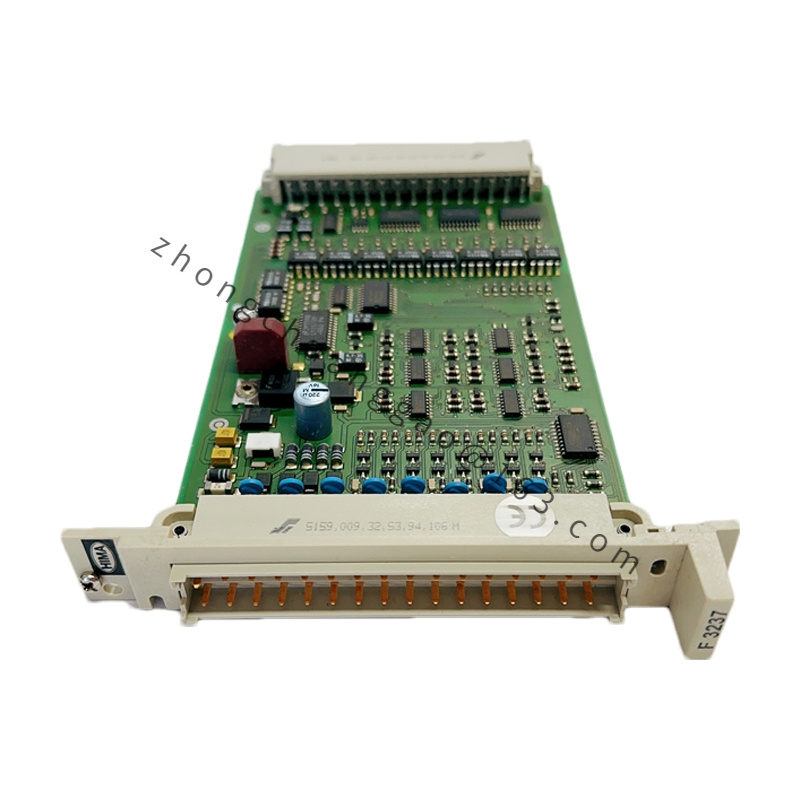

- Input/Output (I/O) Compatibility: Designed to interface with Hima’s core SIS controllers (such as the H41q series) and other compatible I/O modules, ensuring plug-and-play integration.

- Safety Certification: Complies with IEC 61508 (SIL 3) and IEC 61511, meeting the highest safety integrity levels required for critical industrial processes.

- Functional Features:

- Redundant Communication Paths: Incorporates redundant data transmission channels to prevent single-point failures, ensuring continuous communication even if one channel malfunctions.

- Diagnostic Capabilities: Built-in self-diagnostic functions that monitor module health, detect faults (such as connection errors or voltage anomalies), and send real-time alerts to the system controller for prompt troubleshooting.

- Compact Design: Features a space-saving form factor suitable for installation in standard 19-inch racks, optimizing cabinet space utilization in industrial control rooms.

- EMI/RFI Immunity: High resistance to electromagnetic interference (EMI) and radio-frequency interference (RFI), ensuring stable operation in environments with high electrical noise (e.g., near motors or power lines).

- Application Scenarios:

- Oil and Gas Industry: Used in upstream (wellheads, pipelines) and downstream (refineries, petrochemical plants) facilities to enable communication between safety controllers and field devices (e.g., pressure sensors, emergency shutdown valves).

- Chemical Processing Plants: Integrates into SIS for processes involving hazardous materials, ensuring reliable data flow between control systems and safety-critical equipment.

- Power Generation: Applied in thermal power plants or nuclear power auxiliary systems to support communication in safety loops, such as those controlling boiler pressure or turbine shutdown.