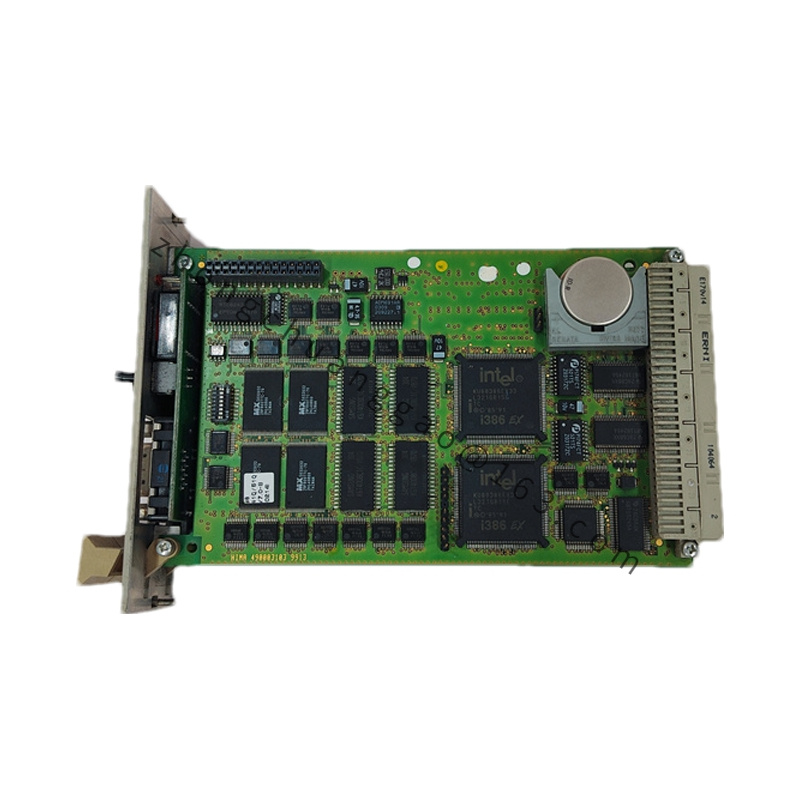

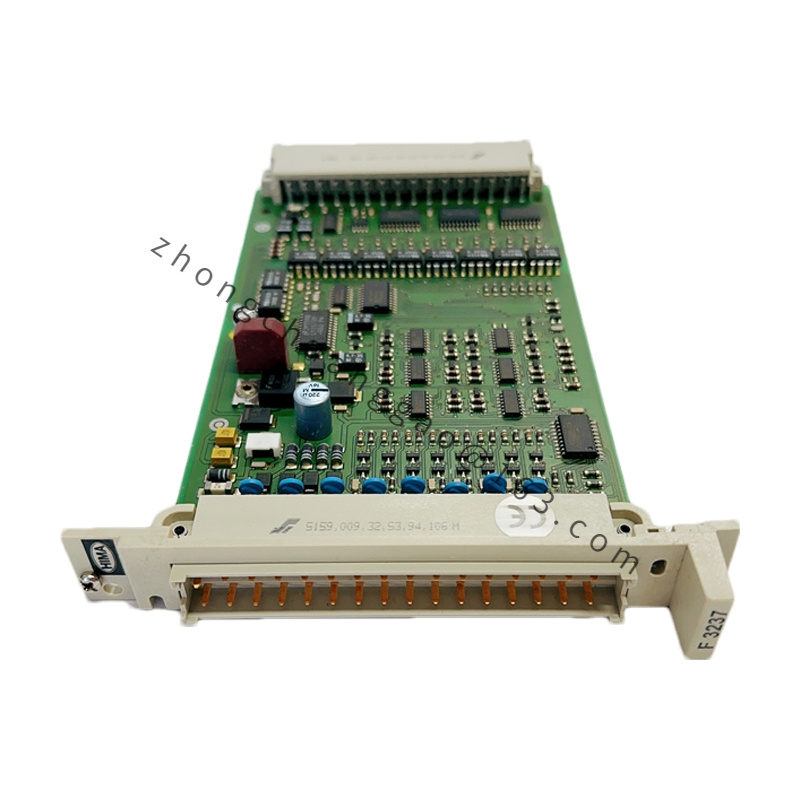

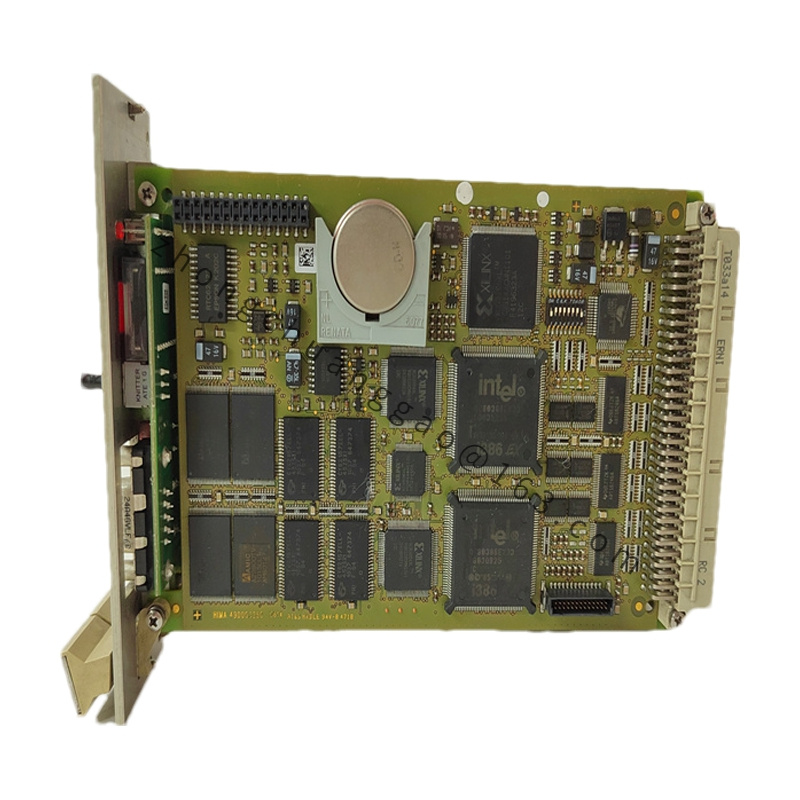

Hima H4135 Safety Controller Module

- Technical Specifications:

- Processing Power: Equipped with a high-performance microprocessor capable of handling complex safety logic (e.g., interlocks, trip conditions) with a processing cycle time of less than 100ms, ensuring rapid response to process deviations.

- Memory Capacity: Includes non-volatile memory (typically 128MB Flash) for storing safety programs and configuration data, and volatile memory (64MB RAM) for real-time data processing.

- Safety Integrity Level (SIL): Certified for IEC 61508 SIL 3 and IEC 61511 SIL 3, making it suitable for the most safety-critical applications.

- Communication Ports: Features multiple built-in communication ports (e.g., Ethernet, Profinet, Modbus) for connecting to I/O modules, human-machine interfaces (HMIs), and plant-wide control systems (DCS).

- Power Requirements: Operates on 24V DC (18V DC to 32V DC) with low power consumption (typically 15W), reducing energy usage in industrial setups.

- Environmental Ratings: IP20 protection class for the module itself (when installed in a closed cabinet), and operating temperature range of -10°C to +55°C.

Detailed content

- Functional Features:

- Redundant Architecture: Adopts a 2-out-of-2D (2oo2D) or 2-out-of-3 (2oo3) redundant design, where multiple processor cores or modules work in parallel to cross-verify data; if one core/module fails, the others continue operation without interruption.

- Flexible Programming: Supports programming via Hima’s proprietary software (e.g., HIMA Planar) using standardized languages such as Function Block Diagram (FBD) and Structured Text (ST), enabling easy customization of safety logic for specific processes.

- Event Logging: Automatically records safety-related events (e.g., trip activations, fault detections) with time stamps (accurate to milliseconds) for post-incident analysis and compliance reporting.

- Online Configuration and Maintenance: Allows for online modification of safety programs (without shutting down the system) and real-time monitoring of module status, minimizing downtime during maintenance.

- Application Scenarios:

- Petrochemical Refineries: Controls emergency shutdown (ESD) systems for reactors, distillation columns, and storage tanks, triggering shutdowns if variables like temperature, pressure, or level exceed safe limits.

- Pharmaceutical Manufacturing: Used in processes requiring strict safety controls (e.g., sterile production, hazardous drug synthesis) to ensure compliance with GMP (Good Manufacturing Practices) and prevent product contamination or equipment damage.

- Water and Wastewater Treatment: Manages safety loops for wastewater treatment plants, particularly in processes involving chlorine disinfection or chemical dosing, where deviations could lead to environmental hazards.