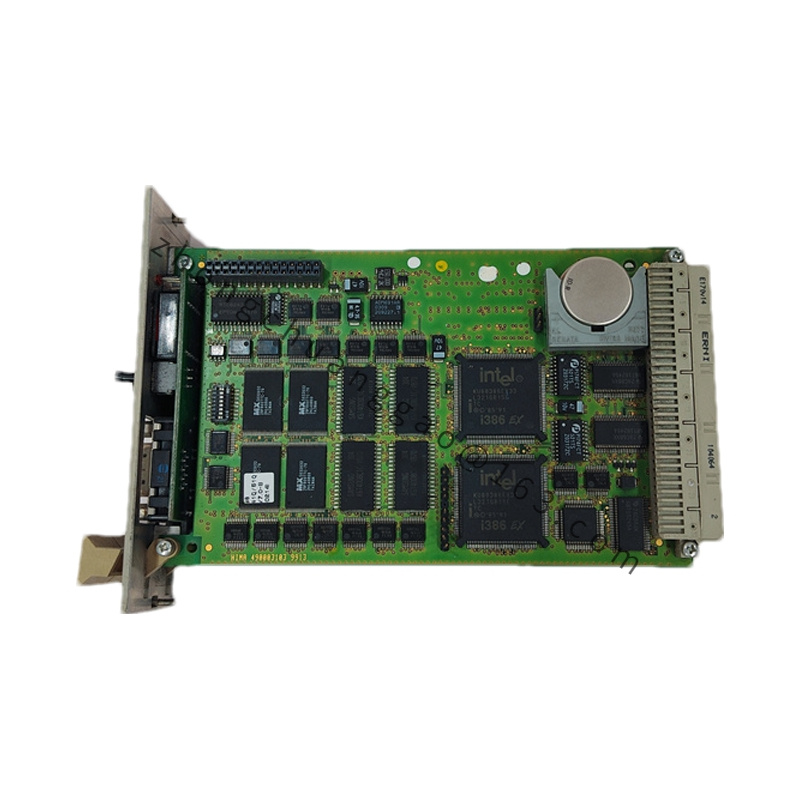

Hima GMP232 Serial Communication Interface Module

- Technical Specifications:

- Serial Port Configuration: Features one or two RS-232 ports, supporting data rates from 300 bps to 115200 bps (configurable via software) to match different device requirements.

- Signal Standards: Complies with EIA/TIA-232-F standards, supporting full-duplex communication with hardware flow control (RTS/CTS) and software flow control (XON/XOFF) options.

- Operating Voltage: 24V DC (±10% tolerance), with a typical current draw of 50mA, ensuring compatibility with standard industrial power supplies.

- Safety and Compliance: Meets IEC 61010-1 (safety for electrical equipment for measurement, control, and laboratory use) and IEC 61326-1 (EMC requirements for industrial control equipment).

- Physical Dimensions: Compact design with dimensions approximately 100mm (length) × 50mm (width) × 25mm (height), suitable for installation in 19-inch racks or small control cabinets.

Detailed content

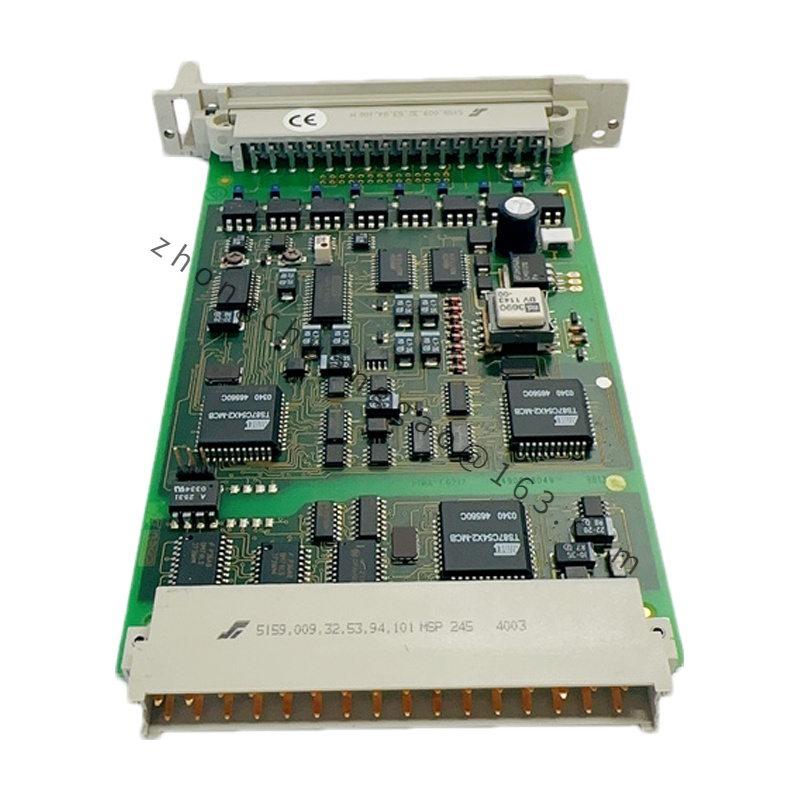

- Functional Features:

- Protocol Support: Compatible with common serial protocols such as Modbus RTU, ASCII, and custom protocols, enabling communication with a wide range of devices (e.g., HMIs, data loggers, remote I/O units).

- Data Integrity Checks: Incorporates parity checking (even, odd, none) and stop bit configuration (1, 1.5, 2 bits) to detect and prevent data transmission errors, ensuring accurate data exchange.

- Isolation: Provides galvanic isolation between the module’s internal circuits and external serial devices (typically 2.5kVrms for 1 minute), protecting the SIS from voltage spikes or ground loops in the field.

- Status Monitoring: Includes LED indicators for power, port activity, and fault conditions (e.g., communication errors), allowing operators to quickly identify and resolve issues.

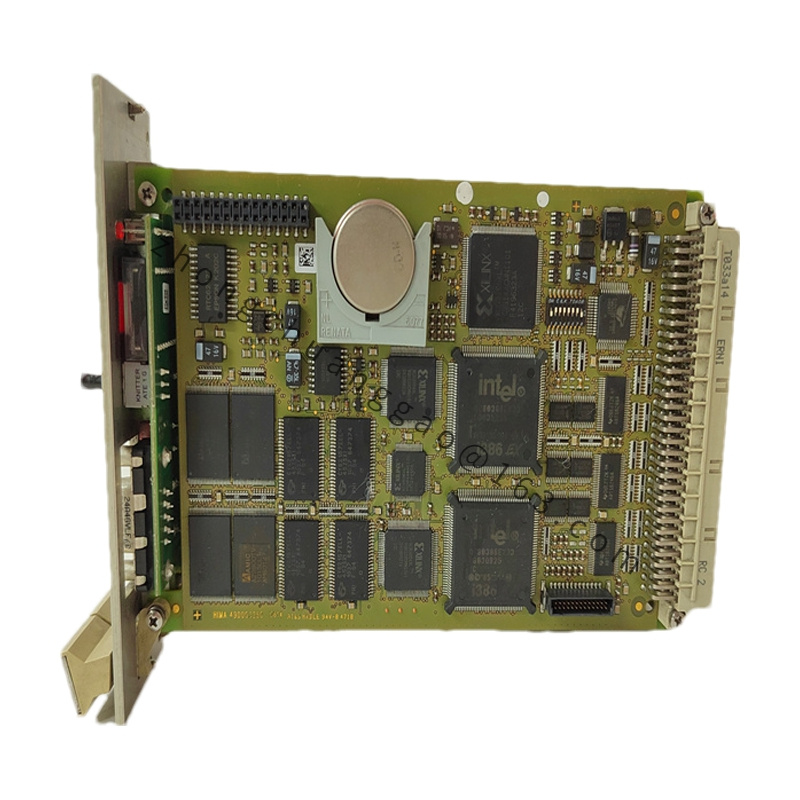

- Application Scenarios:

- Industrial HMIs: Connects Hima SIS to serial-based HMIs, enabling operators to monitor safety system status, view process variables, and acknowledge alarms in real time.

- Data Logging Systems: Transmits safety-related data (e.g., trip events, module status) from the SIS to serial data loggers for long-term storage and compliance reporting (e.g., FDA, OSHA requirements).

- Remote Monitoring Devices: Facilitates communication between the SIS and remote serial sensors (e.g., temperature sensors in remote pipelines) in oil and gas or water treatment applications, where wired Ethernet connectivity is not feasible.