Detailed content

Technical Specifications

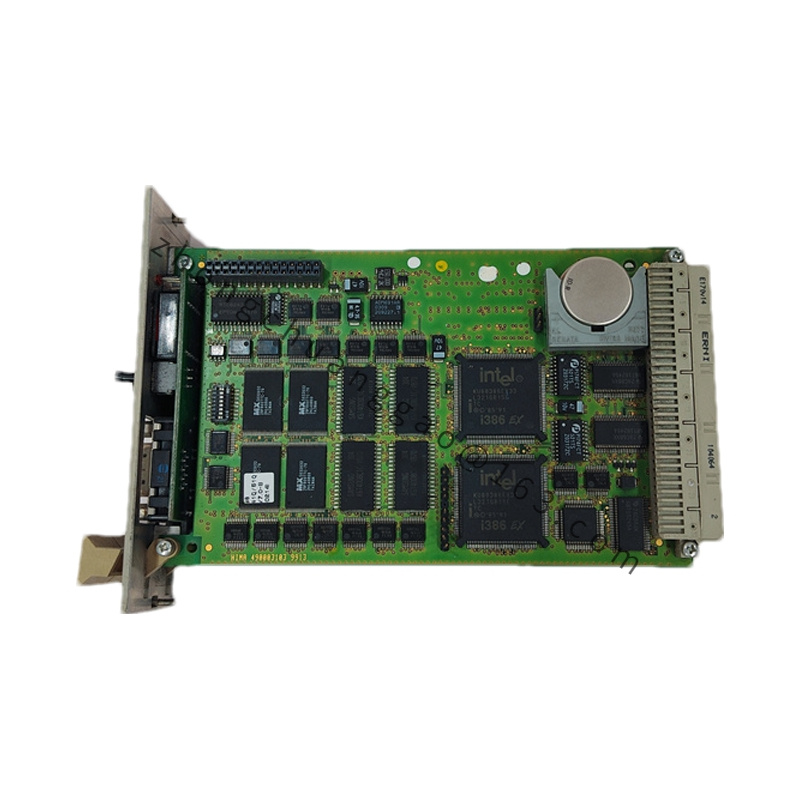

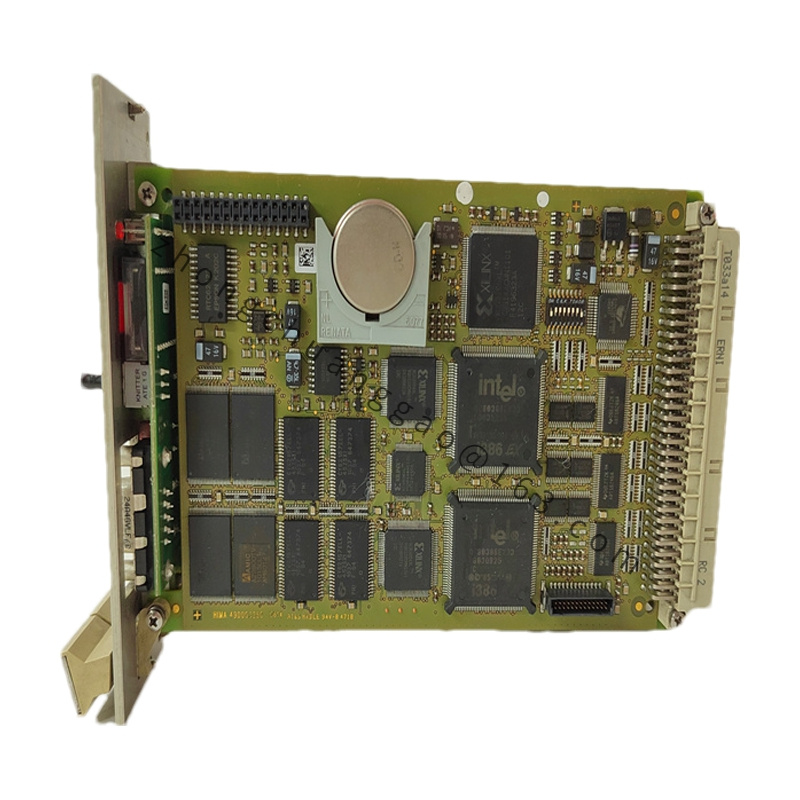

- Processor and Performance:

- Utilizes a high-performance industrial-grade processor for reliable and fast processing.

- Designed to handle complex safety functions with high reliability.

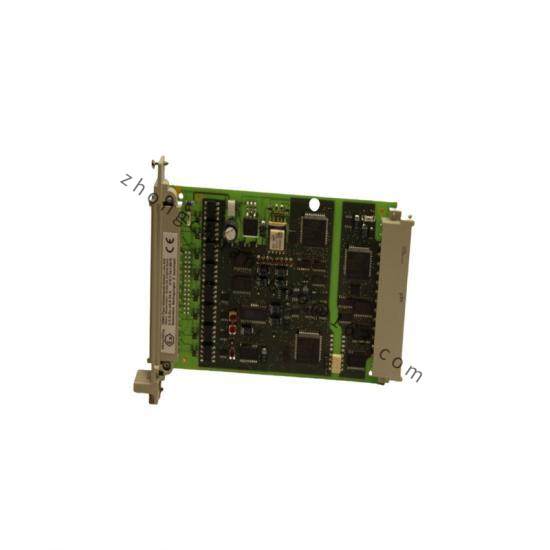

- I/O Modules:

- Supports a wide range of I/O modules, including digital inputs, digital outputs, analog inputs, and analog outputs.

- Modular design allows for flexible configuration according to system needs.

- Communication Interfaces:

- Multiple communication protocols supported, such as Profibus, Modbus, Ethernet/IP, and others.

- Redundant communication interfaces for enhanced system reliability.

- Power Supply:

- Typically operates on a 24V DC power supply, with redundancy options available for critical applications.

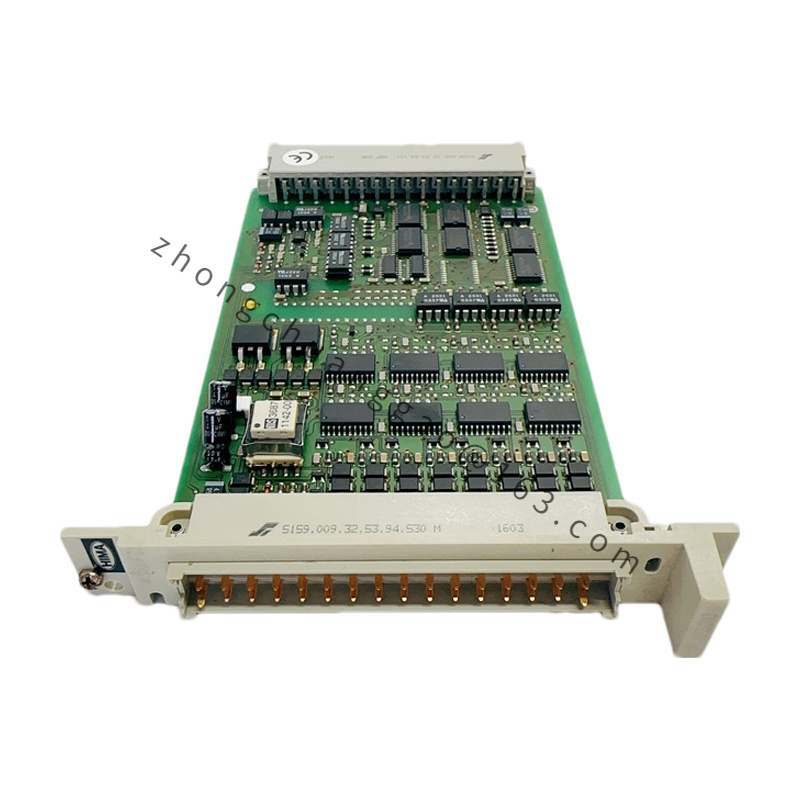

- Dimensions and Mounting:

- Designed for compact installation in standard control cabinets.

- Suitable for DIN rail mounting, making it easy to integrate into existing systems.

Functional Features

- Safety Compliance:

- Complies with international safety standards such as IEC 61508 and ISO 13849.

- Provides redundant processing and self-diagnostic capabilities to ensure high availability and safety.

- Flexible Programming:

- Supports various programming languages including Ladder Diagram (LD), Function Block Diagram (FBD), and Structured Text (ST).

- Offers graphical programming tools for easier configuration and setup.

- Real-Time Performance:

- Capable of high-speed processing for real-time control and monitoring.

- Ensures fast response times to changes in the system or process.

- Diagnostics and Maintenance:

- Equipped with diagnostic tools and LED indicators to monitor system status and troubleshoot issues.

- Supports remote diagnostics and maintenance capabilities for ease of management.

Application Scenarios

- Industrial Automation:

- Ideal for controlling and monitoring industrial processes, such as manufacturing lines, production systems, and equipment.

- Safety-Critical Applications:

- Used in industries where high safety standards are required, such as chemical processing, pharmaceuticals, energy, and transportation.

- Redundant Systems:

- Suitable for applications requiring high system availability and fault-tolerant operation, such as critical infrastructure and redundant control systems.

- Process Control:

- Effective in managing complex processes where safety and reliability are critical, including batch processing and continuous operations.

Additional Considerations

- Software Support: Hima provides specialized software tools for configuration, programming, and monitoring, which include device management and process control software.

- Compatibility: Ensure compatibility with existing automation devices and systems for seamless integration into your current infrastructure.