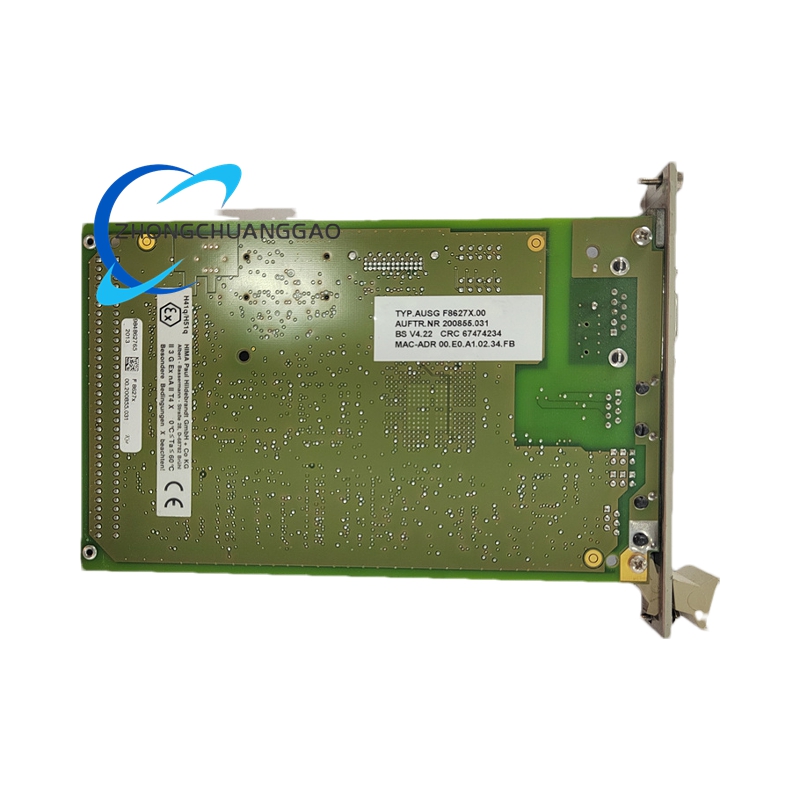

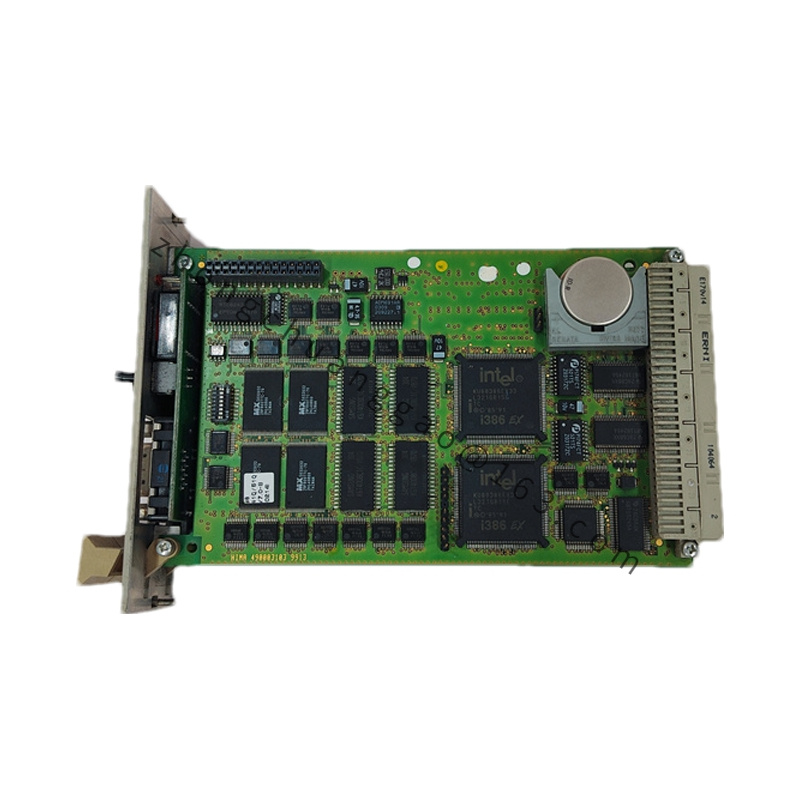

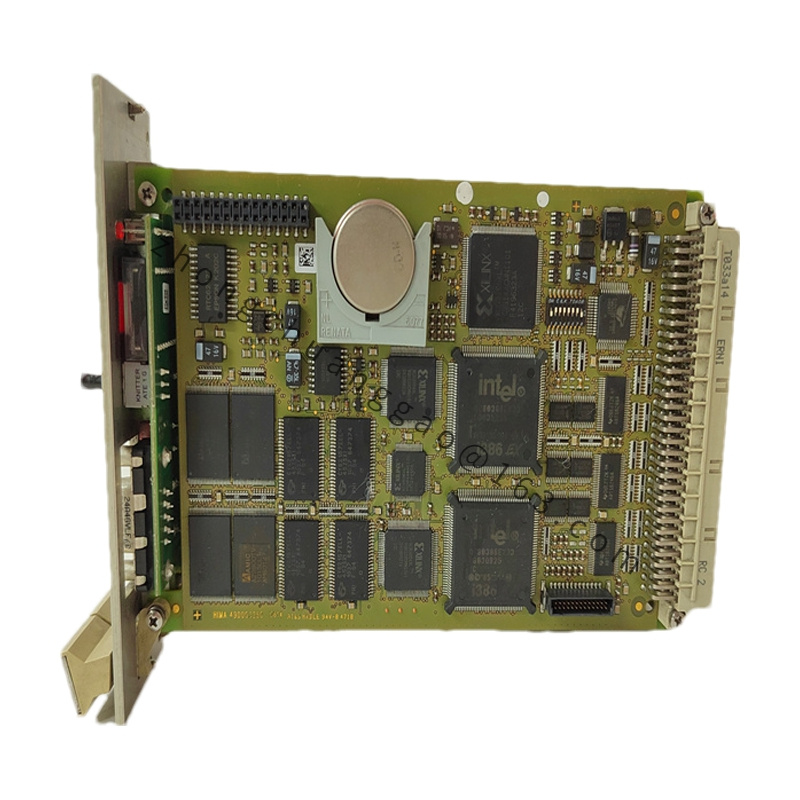

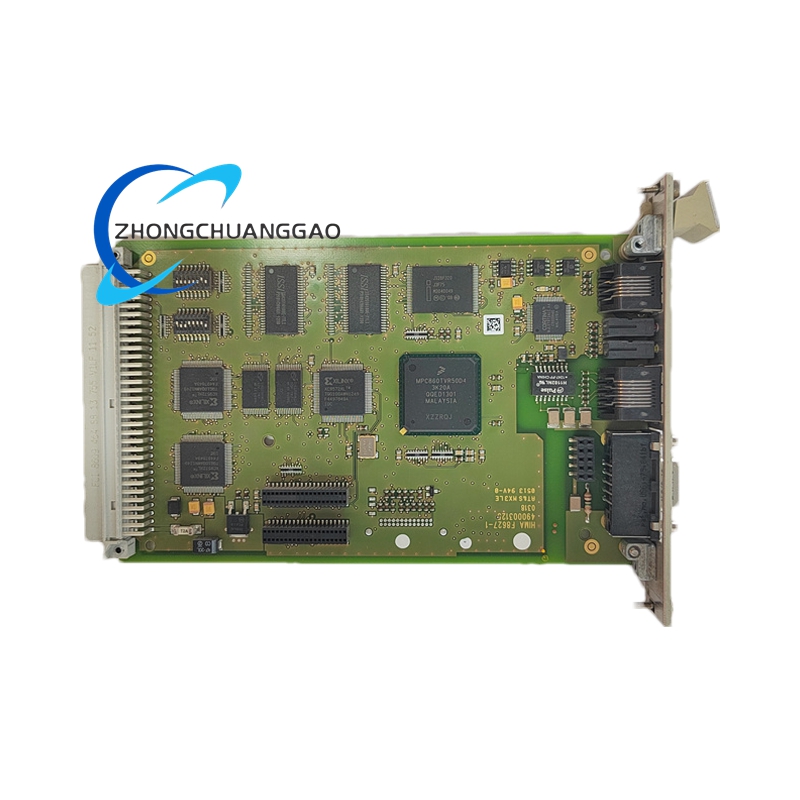

HIMA F8627X Industrial Safety Communication Module

Safety Programmable Logic Controller (PLC) Module

Technical Specifications

- Series: Part of the HIMA H400 or H500 series (exact series may vary based on configuration)

- CPU Architecture: High-speed, fault-tolerant processor optimized for real-time safety logic execution

- Memory: Integrated program and data memory with battery-backed or non-volatile storage for safety-critical data

- Input/Output (I/O) Handling: Supports connection to HIMA I/O modules via secure backplane or fieldbus communication

Detailed content

- Communication Interfaces:

- Ethernet (for engineering, diagnostics, and integration with DCS/SCADA)

- PROFIBUS, MODBUS, or FOUNDATION Fieldbus (optional, depending on configuration)

- HIMA Safety Bus (HISB) for redundant communication within the safety system

- Redundancy: Supports hot-standby and dual-redundant configurations for high availability

- Safety Integrity Level (SIL): Certified up to SIL 3 according to IEC 61508 and IEC 61511

- Programming Standards: Compliant with IEC 61131-3 (supports FBD, LD, ST, SFC, IL)

- Real-Time Performance: Deterministic scan times in milliseconds for fast response to safety events

- Power Supply: Typically operates on 24 V DC with redundant power input options

- Operating Temperature Range: -20°C to +60°C

- Environmental Protection: Designed for industrial environments with resistance to shock, vibration, and EMI

Functional Features

- High Safety Availability: Engineered for continuous operation with minimal downtime using redundant components

- Built-in Diagnostics: Comprehensive self-monitoring of CPU, memory, power, communication, and I/O status

- Secure Firmware: Protected against unauthorized access and tampering, ensuring integrity of safety logic

- Modular Architecture: Allows flexible system expansion with various I/O and communication modules

- Online Maintenance: Supports module replacement and configuration updates without shutting down the process

- Cybersecurity Features: Includes authentication, access control, and secure communication protocols

- Time Synchronization: Supports NTP or IRIG-B for precise event logging and system coordination

Application Scenarios

- Oil and Gas: Used in emergency shutdown (ESD), fire and gas detection (F&G), and burner management systems (BMS)

- Chemical and Petrochemical: Implements safety interlocks, reactor protection, and toxic gas monitoring

- Power Generation: Applied in turbine protection, boiler control, and nuclear safety systems

- Refining and Processing: Ensures safe operation of distillation units, compressors, and pressure vessels

- Renewable Energy: Utilized in biogas plants and hydrogen production facilities for process safety

- Industrial Manufacturing: Protects high-risk processes such as high-pressure molding, chemical mixing, and storage tank farms