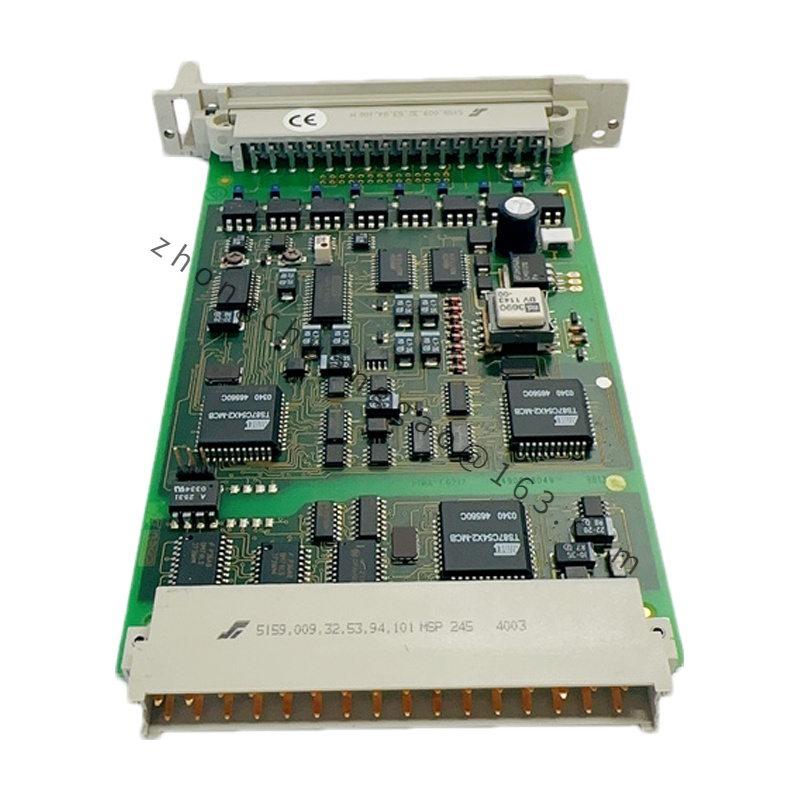

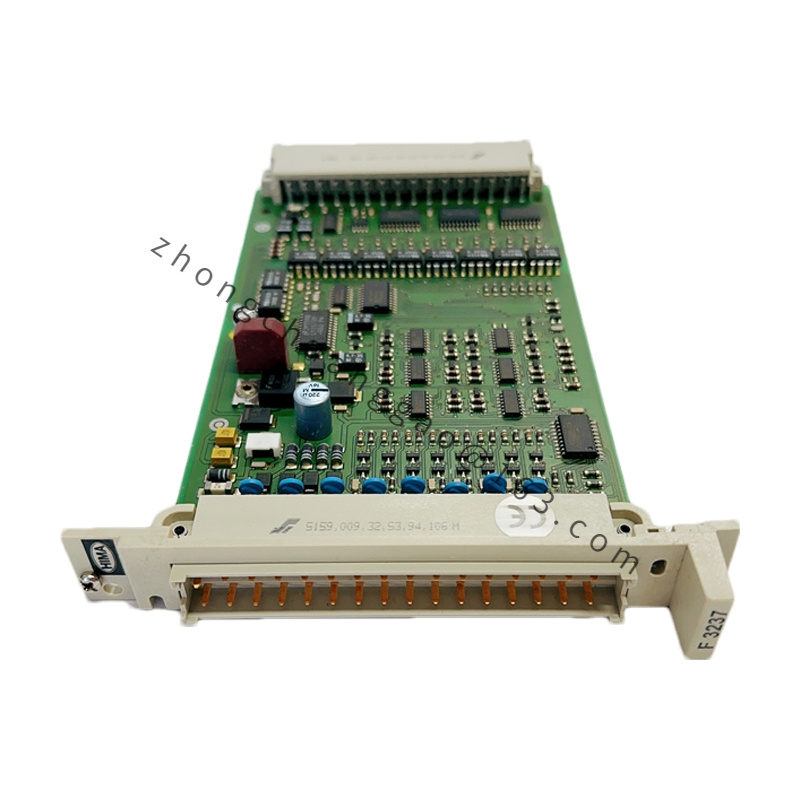

HIMA F3DIO20/802–Digital Safety I/O Module

Technical Specifications

- Power Supply: It is powered by 24V DC, with a tolerance of – 15% to +20%.

- Input Current: The maximum load current can reach 8A, and the idle current is about 0.4A at 24V. An external 10A time – lag (t) fuse is required.

- Digital I/O Channels: It has 20 digital input channels and 8 digital output channels.

- Communication Interface: It is equipped with 2 RJ – 45 Ethernet interfaces, supporting 10Base – T/100Base – TX, and has an integrated switch.

- Operating Temperature Range: It can work normally in the temperature range of 0°C to +60°C.

- Storage Temperature Range: The storage temperature range is – 40°C to +85°C.

- Protection Level: The protection level is IP20.

- Size and Weight: The specific size information is not clearly given, but it is a compact – designed module, weighing only 0.1 kg.

Detailed content

Function Features

- High – reliability Safety Design: It is designed for safety – critical systems, meeting high – level reliability and fault – tolerance standards, and is suitable for applications with high – safety requirements.

- Redundancy Support: It supports redundant configurations, which can ensure the availability and safety of the system and reduce the risk of system failures.

- Built – in Diagnostic Function: It has a built – in diagnostic function, which can monitor the operating status of the module and connected devices, and can quickly detect faults, facilitating maintenance and troubleshooting.

- Hot – swappable: It supports hot – swapping, which means that the module can be replaced without shutting down the entire system, thereby minimizing the system downtime and improving the maintainability.

- Good Compatibility: It is compatible with the HIMatrix safety PLC system and can be seamlessly integrated into larger safety systems to realize complex control functions.

Application Scenarios

- Oil and Gas Industry: It is used in safety – related control systems of oil and gas production facilities, such as emergency shutdown systems, to ensure the safe operation of the production process.

- Chemical Industry: In chemical plants, it is used for the control and safety monitoring of chemical reaction devices, storage tanks and other equipment, and can quickly respond to potential safety hazards.

- Power Generation Industry: It is applied to the safety control of power generation equipment, such as the protection and control of steam turbines and gas turbines, to ensure the stable operation of the power generation system.

- Rail Industry: In the rail transit field, it is used for the safety control of railway signaling systems, train control systems, etc., to ensure the safe operation of trains.