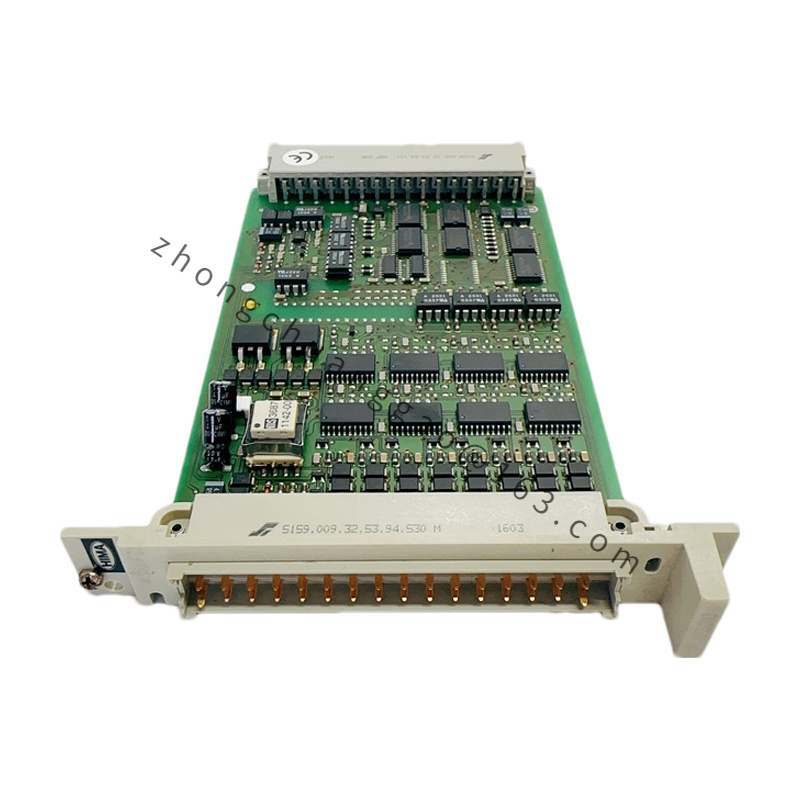

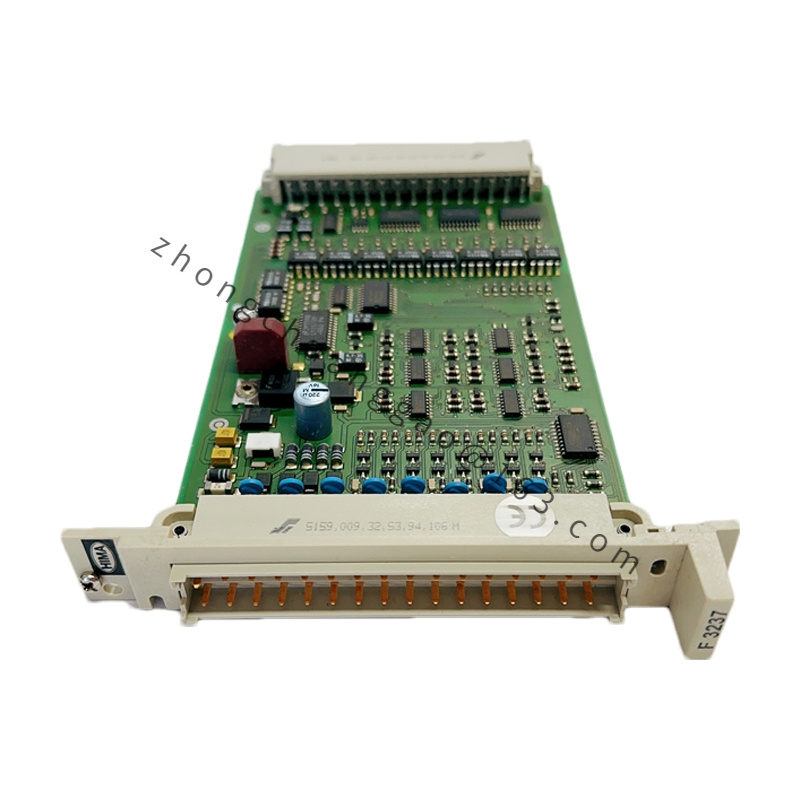

Hima F3333 Safety-Related Input/Output (I/O) Module

- Technical Specifications:

- I/O Channels: Typically includes 8 digital input channels and 8 digital output channels (configurable for specific applications), supporting both sinking and sourcing output configurations.

- Input Specifications: Digital inputs accept 24V DC signals, with a response time of less than 10ms (for safety-critical signals) and a maximum input current of 5mA per channel. Inputs are protected against reverse polarity and overvoltage (up to 36V DC).

- Output Specifications: Digital outputs provide 24V DC, with a maximum current rating of 1A per channel (or 4A total for the module) and short-circuit protection to prevent damage from wiring faults.

- Safety Certification: Complies with IEC 61508 SIL 2/SIL 3 and IEC 61511, ensuring compatibility with safety loops requiring mid-to-high safety integrity levels.

- Operating Environment: Operating temperature range of -20°C to +60°C, and humidity tolerance of 5% to 95% (non-condensing), suitable for harsh industrial conditions.

- Communication: Interfaces with Hima SIS controllers via a proprietary backplane bus (e.g., Hima’s Safety Bus) for high-speed data transmission (up to 100Mbps).

Detailed content

- Functional Features:

- Channel-Level Diagnostics: Each input and output channel includes independent diagnostic functions to detect faults such as open circuits, short circuits, or signal loss. Faults are reported to the SIS controller in real time for immediate action.

- Hot-Swappable Design: Allows the module to be removed and replaced while the SIS is operational, eliminating downtime for maintenance or repairs—a critical feature for continuous-process industries.

- Redundant Power Inputs: Features two independent power inputs (24V DC) to ensure the module remains operational even if one power source fails, enhancing system reliability.

- Compatibility: Fully compatible with Hima’s range of safety controllers (e.g., H41q, H51q series) and software tools (e.g., HIMA Planar), enabling seamless integration into existing SIS setups.

- Application Scenarios:

- Chemical Plants: Used to connect field devices (e.g., pressure switches, level sensors) as inputs and control devices (e.g., solenoid valves, alarm buzzers) as outputs in safety loops for reactor temperature or pressure control.

- Food and Beverage Industry: Integrates into SIS for processes like pasteurization or sterilization, where input channels monitor temperature sensors and output channels trigger emergency cooling systems if temperatures exceed safe limits.

- Automotive Manufacturing: Applied in paint booths or assembly lines with safety-critical equipment, where input channels detect door interlocks (to prevent access during operation) and output channels stop machinery if interlocks are violated.