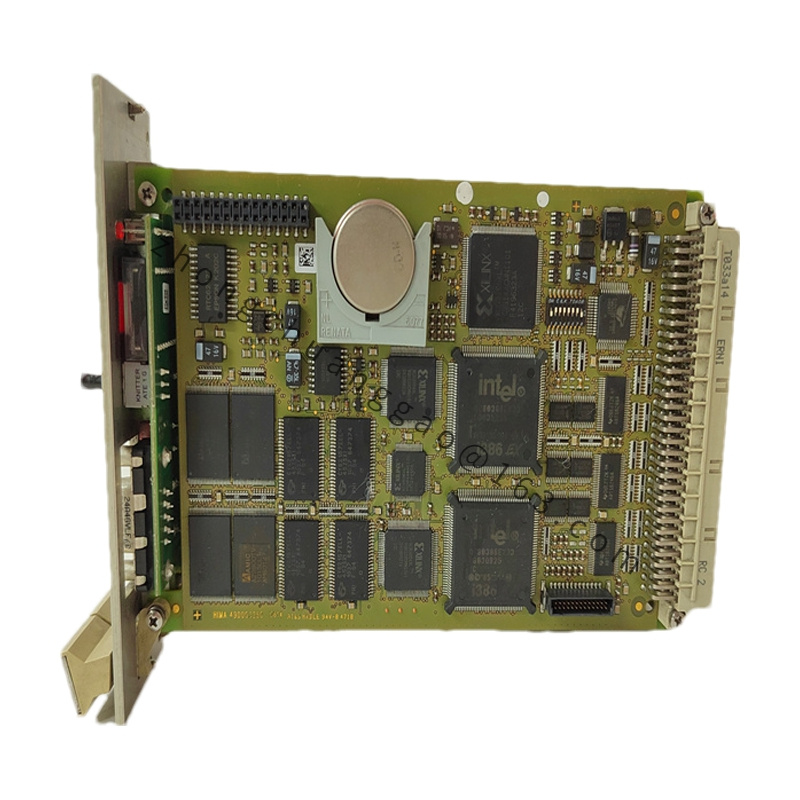

Hima DIO216 Digital Input/Output (DIO) Module

- Technical Specifications:

- I/O Channel Count: Provides 16 digital input channels and 16 digital output channels (total 32 channels), offering high I/O density for compact installations.

- Input Voltage and Current: Digital inputs support 24V DC (nominal), with a minimum input current of 2mA (to detect valid signals) and a maximum input voltage of 30V DC (overvoltage protection). Input response time is adjustable (5ms to 100ms) to filter out electrical noise.

- Output Voltage and Current: Digital outputs supply 24V DC, with a maximum current rating of 0.5A per channel (or 8A total for the module). Outputs include short-circuit protection (via self-resetting fuses) and overload protection to prevent damage.

- Safety and EMC Compliance: Certified to IEC 61508 (SIL 2) for safety-related applications and IEC 61326-1 (EMC Class A) to withstand electromagnetic interference in industrial settings.

- Power Consumption: Typically 10W when fully loaded (all channels active), operating on 24V DC (18V DC to 32V DC) with reverse polarity protection.

- Physical Design: Designed for 19-inch rack mounting, with dimensions of approximately 140mm (height) × 100mm (width) × 200mm (depth), and a weight of around 500g.

Detailed content

- Functional Features:

- Configurable I/O Channels: Input channels can be configured for normally open (NO) or normally closed (NC) operation via software, adapting to different field device requirements (e.g., NO pressure switches vs. NC door interlocks).

- Grouped Output Control: Output channels can be grouped into logical sets (e.g., 4-channel groups) to execute synchronized commands (e.g., activating multiple valves simultaneously), simplifying safety logic programming.

- Real-Time Status Monitoring: Each channel has an LED indicator (green for active, red for fault) on the module front panel, allowing operators to visually inspect channel status without accessing software.

- Remote Diagnostics: Supports remote monitoring and diagnostics via the SIS controller, enabling maintenance teams to check module health, view fault logs, and perform troubleshooting from a central location.

- Application Scenarios:

- Manufacturing Facilities: Used in assembly lines or packaging machines to connect multiple sensors (e.g., proximity sensors for part detection) as inputs and actuators (e.g., conveyor motors, robotic arms) as outputs, controlling production sequences and safety interlocks.

- Water Treatment Plants: Integrates into control systems for pumping stations, where input channels monitor flow meters and level sensors, and output channels control pump on/off cycles or valve positions to maintain water pressure and prevent overflow.

- Mining Industry: Applied in underground mining operations to monitor equipment status (e.g., conveyor belt alignment sensors) via input channels and control safety devices (e.g., emergency stop signals, ventilation fans) via output channels, ensuring worker safety.