Detailed content

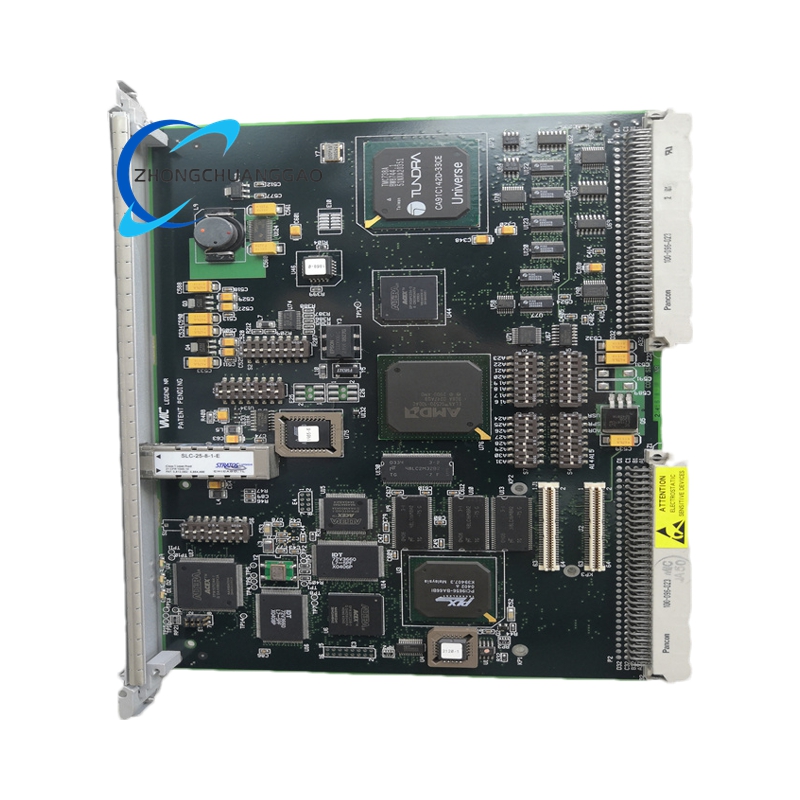

Technical Specifications:

- Input/Output Architecture:

- 8 isolated differential input channels for thermocouple signals, supporting types J, K, T, E, R, S, B, and N simultaneously.

- 12-bit analog-to-digital converter (ADC) with ±0.1% linearity and 100Hz sampling rate, ensuring precise temperature measurement.

- Cold junction compensation via built-in temperature sensor, eliminating external calibration needs.

- Interfaces:

- VMEbus Compliance: Full VME64 compatibility (A32/D32 addressing) with P1/P2 connectors for seamless integration into VME backplanes.

- Signal Termination: Screw-terminal block for direct thermocouple connections, supporting 24AWG to 18AWG wires.

- Optional Configuration: High-level input mode for non-thermocouple signals (e.g., 0–10V DC).

- Electrical:

- Power: +5V DC (max 2A) and ±12V DC (max 0.5A), with reverse polarity protection.

- Isolation: 2500V DC isolation between input channels and VMEbus.

- Environmental:

- Operating Temperature: -40°C to +85°C (extended industrial grade), with resistance to shock (50g, 11ms) and vibration (10g, 10–2000Hz).

- Mechanical: 6U VME form factor (3U height) with rugged metal enclosure for harsh environments.

Functional Features:

- Signal Conditioning:

- Automatic Linearization: Built-in algorithms convert raw thermocouple voltages to calibrated temperature values (-200°C to +1800°C range).

- Filtering: 8-pole Butterworth filter (10Hz cutoff) to reduce noise in high-interference environments.

- Error Handling:

- Open/Short Circuit Detection: Real-time monitoring of thermocouple integrity with status flags.

- Overvoltage Protection: 30V DC transient protection on input channels.

- Configuration Flexibility:

- Jumpers/DIP Switches: Selectable channel grouping, filter settings, and thermocouple types.

- DMA Support: Direct memory access for high-speed data transfer to VMEbus master modules.

- Software Integration:

- Drivers: Pre-written VMEbus device drivers for Linux, VxWorks, and Windows Embedded.

- API Libraries: C/C++ and Python libraries for custom application development.

Application Scenarios:

- Industrial Process Control:

- Chemical Reactors: Monitors temperature profiles in batch reactors, enabling closed-loop control of heating/cooling systems.

- Food Processing: Ensures sterilization processes meet FDA standards by tracking conveyor belt temperatures in pasteurization lines.

- Energy Production:

- Steam Turbines: Measures blade temperatures in power plants to optimize maintenance schedules and prevent overheating.

- Solar Farms: Monitors photovoltaic panel temperatures to improve energy conversion efficiency.

- HVAC Systems:

- Chiller Plants: Controls refrigerant flow based on real-time temperature data from multiple zones.

- Data Centers: Maintains optimal server room temperatures by integrating with CRAC units.

- Research Laboratories:

- Material Testing: Records thermal expansion rates of composites under extreme temperature cycling.

- Cryogenic Systems: Monitors liquid nitrogen levels and temperature stability in MRI magnet systems.

- Transportation:

- Railway Engines: Tracks cylinder head temperatures in diesel locomotives for predictive maintenance.

- Aerospace Testing: Validates thermal performance of aircraft components in wind tunnel simulations.

Discover our other products

GE IS200VRTDH1DAB

GE IS215ACLEH1BB

GE V7768-320001 350-9301007768-320001A2

GE VME-7865RC 332-93007865

GE Fanuc A06B-6088-H001

GE Fanuc IC200MDL640K

GE Fanuc IC200UDD110-CH

GE Fanuc IC693MDL732E

GE Fanuc IC697HSC700

GE Fanuc 44A297050-G01