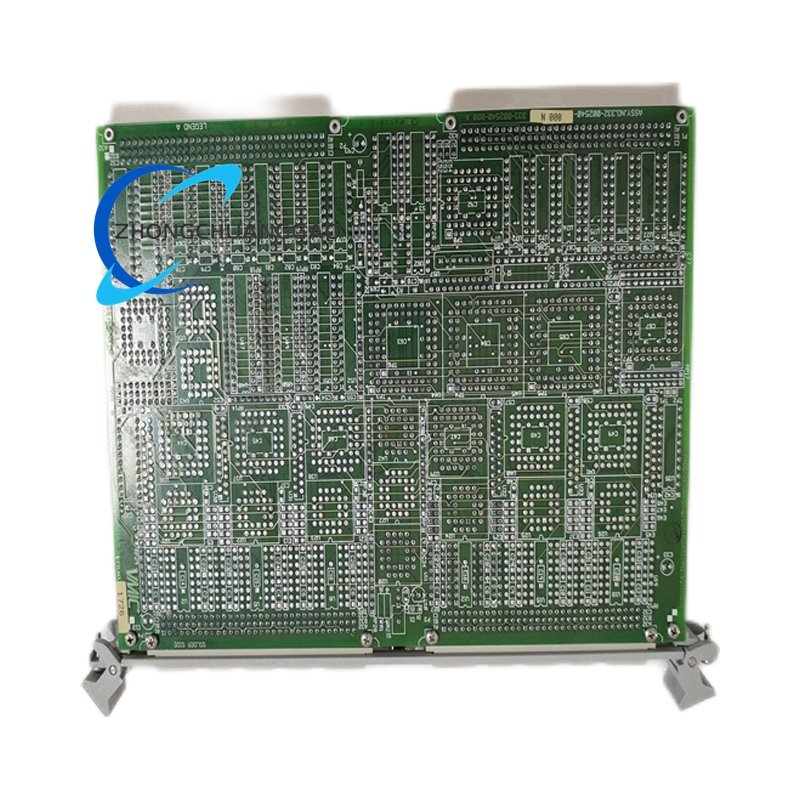

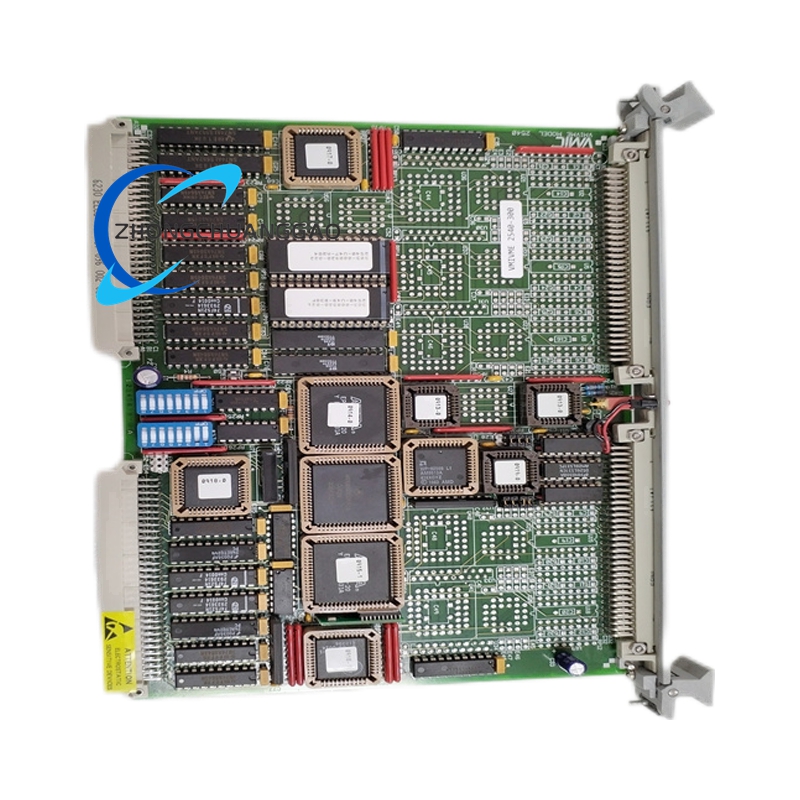

GE VMIVME-2540 Intelligent Counter/Controller

1. Technical Specifications

• Processor: on-board 15 MHz 68HC000 CPU

• Counting depth: up to 4 billion events per channel

• Frequency range: 1.16 × 10⁻³ Hz to 2.5 MHz

• Period / pulse-width window: 400 ns to 8.5899 × 10⁶ s (32-bit floating-point) or 858 s (unsigned integer)

• Channels: 4, 8, 16 or 24 software-selectable configurations

• Output drive: 24 discrete outputs, ±10 V at 10 mA per channel, 12-bit resolution

• Step rate for quadrature position control: up to 1.25 MHz with ¼-wave resolution

• VMEbus interface: A32/A24/D32/D16/D8 slave, 64 kbyte memory window, ANSI/IEEE 1014-1987

Detailed content

compliant

• Data format: ANSI/IEEE 754-1985 32-bit floating-point

• Local timing: six programmable System Timing Controllers (STCs) each offering four high-speed counter / waveform synthesis ports

• Isolation: RS-422 differential or single-ended TTL I/O options

• Power: single-slot 6U VME, +5 V DC only

• Data format: ANSI/IEEE 754-1985 32-bit floating-point

• Local timing: six programmable System Timing Controllers (STCs) each offering four high-speed counter / waveform synthesis ports

• Isolation: RS-422 differential or single-ended TTL I/O options

• Power: single-slot 6U VME, +5 V DC only

2. Functional Highlights

• Continuous measurement mode runs without host CPU intervention, freeing system resources

• Command-driven memory-mapped user interface—no low-level timing programming required

• Real-time pulse-train, square-wave and PWM generation with programmable duty cycle

• Quadrature decoding for rotary shafts, linear encoders and robotic joints

• Built-in self-test and diagnostics accessible via VMEbus

• Continuous measurement mode runs without host CPU intervention, freeing system resources

• Command-driven memory-mapped user interface—no low-level timing programming required

• Real-time pulse-train, square-wave and PWM generation with programmable duty cycle

• Quadrature decoding for rotary shafts, linear encoders and robotic joints

• Built-in self-test and diagnostics accessible via VMEbus

3. Application Scenarios

• Rotating machinery monitoring: angular position, velocity and acceleration on motors, turbines and spindles

• Automotive testing: brake, transmission and tachometer validation rigs

• Robotics: joint position feedback and trajectory generation

• Telescope / observatory: high-resolution tracking and pointing control

• Medical and laboratory instruments: precision timing and sample positioning

• Elevators, overhead cranes, X-Y tables, machine tools and automated storage/retrieval systems

• Rotating machinery monitoring: angular position, velocity and acceleration on motors, turbines and spindles

• Automotive testing: brake, transmission and tachometer validation rigs

• Robotics: joint position feedback and trajectory generation

• Telescope / observatory: high-resolution tracking and pointing control

• Medical and laboratory instruments: precision timing and sample positioning

• Elevators, overhead cranes, X-Y tables, machine tools and automated storage/retrieval systems

4. Installation & Expansion

• Plugs directly into any standard 6U VME chassis; supports daisy-chained interrupt lines for multi-card synchronisation

• Firmware upgradeable in-system via VMEbus

• Compatible with VMIC VMIVME-7614 CPU boards and VMIVME-5588 reflective memory for distributed control

• Plugs directly into any standard 6U VME chassis; supports daisy-chained interrupt lines for multi-card synchronisation

• Firmware upgradeable in-system via VMEbus

• Compatible with VMIC VMIVME-7614 CPU boards and VMIVME-5588 reflective memory for distributed control

5. Ordering Package

• VMIVME-2540 module (channel count ordered as suffix)

• 6U VME front-panel kit and extraction lever

• User manual (paper and PDF)

• Factory calibration certificate

• VMIVME-2540 module (channel count ordered as suffix)

• 6U VME front-panel kit and extraction lever

• User manual (paper and PDF)

• Factory calibration certificate