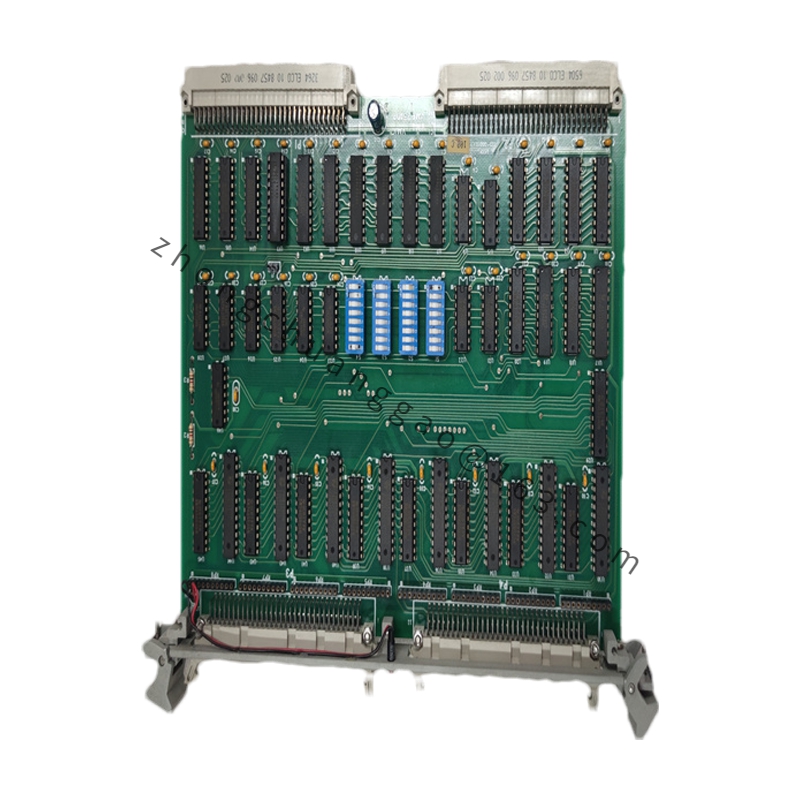

GE VMIVME-2510B

Technical Specifications

Type: 64-bit TTL Digital Input/Output Module

Compatibility: Compliant with VMEbus specifications, double-high form factor

Input/Output Connectors: Dual 64-pin connectors, conforming to DIN41612 standard

I/O Organization: Eight I/O ports, each 8-bit wide, can be addressed individually within short-monitored or short-nonprivileged I/O mappings

Addressing Scheme: Ports can be addressed separately on 8-bit or 16-bit boundaries, with address DIP switches providing unlimited short data I/O address mapping options

Detailed content

Power Requirements: +5V, 3.786A (maximum)

Temperature Range: Operating 0°C to 55°C, storage -20°C to 85°C

Humidity Range: 20% to 80% RH, non-condensing

I/O Circuitry: Supports TTL logic levels, with transceiver options for high-current (64mA) output using SN74AS645 for TTL I/O, and SN74AS641 for open-collector output

Functional Features

Programmable I/O Ports: Each 8-bit port’s direction can be programmed independently, allowing flexible configuration of input or output functionality

High Current Capability: Provides 64mA sink current capability (15mA source)

Built-in Test Logic: Supports real-time or offline mode readout of output data, enabling fault detection and isolation

Fault LED Indicator: A front panel LED indicates faults, turning on during power-up or reset and can be turned off programmatically after successful diagnostics

Control and Data Register Independence: Independent board address decoding for control and data registers

Subsystem Configuration: Supports subsystem configuration, allowing for continuous I/O address assignments and CSR address switches for mapping CSRs to contiguous memory locations

Application Scenarios

Industrial Automation and Control Systems: The VMIVME-2510B is ideal for use in industrial automation and control systems, where it can communicate with various devices and sensors on factory production lines.

Process Control: By monitoring and controlling input/output signals, it enables precise control of production processes, ensuring quality and efficiency.

Automation System Integration: It can be integrated with other automation equipment and systems such as PLCs (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition) systems, facilitating automated control and monitoring of production processes.

Data Collection and Analysis: Capable of collecting various data (e.g., temperature, pressure, flow rates) during production, which can be used for real-time monitoring, process analysis, and optimization of production efficiency and quality.

Safety Monitoring: Can be integrated with safety systems to monitor safety status in production environments, ensuring safety through the detection of safety device input signals and triggering appropriate output signals.