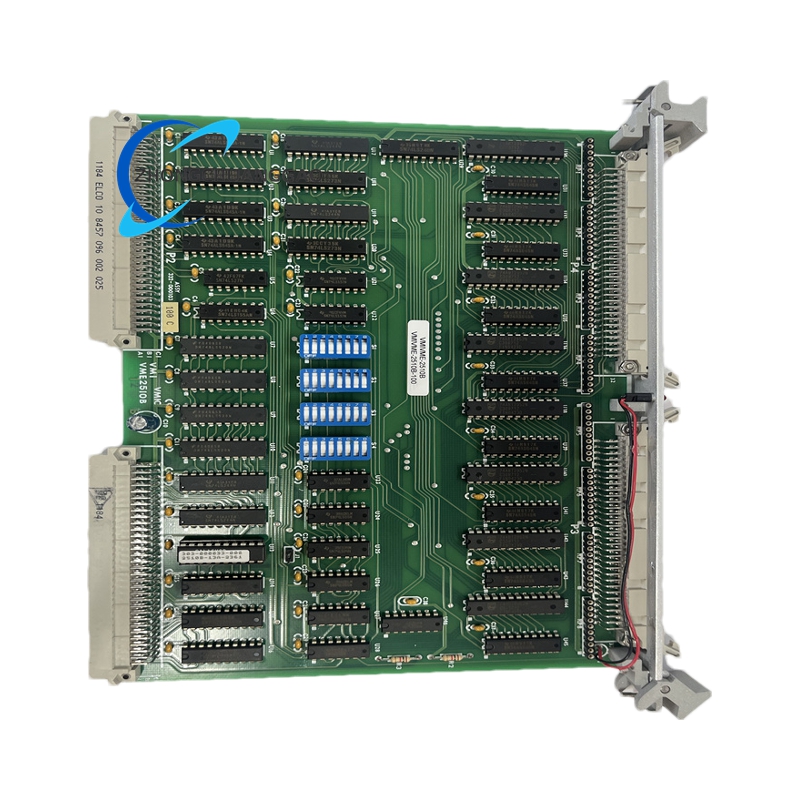

GE VMIVME-2200

1. Core Architecture

- Function: High-density relay output board for industrial control systems .

- Relay Channels: 16–32 independent relay outputs (electromechanical or solid-state variants) .

- Switching Capacity:

- AC Loads: Up to 250V AC / 5A per channel .

- DC Loads: Up to 30V DC / 5A per channel .

- Isolation: Optical isolation (≥1,500V channel-to-bus) for noise immunity and safety .

- Bus Interface: VME64-compliant (A16/A24 addressing) with 16-bit data transfer .

Detailed content

2. Control & Diagnostics

- Status Monitoring: Per-channel LED indicators for relay state (energized/de-energized) .

- Built-in Test (BIT):

- Self-diagnostics verify relay coil integrity and contact functionality .

- Fault reporting via VMEbus interrupts (IRQ1–IRQ7) .

- Response Time: ≤10 ms (electromechanical); ≤1 ms (solid-state) .

3. Electrical & Environmental

- Power Requirements: +5VDC ±5% (logic), +12V to +24VDC (relay coil drive) .

- Operating Temperature: 0°C to +60°C (industrial standard) .

- Humidity: 5–95% non-condensing .

- Compliance: CE Mark, RoHS, and industrial EMC immunity (CISPR 22) .

Functional Features

- High-Reliability Switching:

- Gold-plated contacts minimize arcing and extend lifespan (≥1 million cycles) .

- Flyback diodes suppress voltage spikes during inductive load switching (e.g., solenoids, motors) .

- Flexible Configuration:

- Programmable Latching/Non-Latching Modes: Sustains relay state during power loss (latching) or auto-resets (non-latching) .

- Per-Channel Control: Independent activation via VMEbus writes .

- Fault Tolerance:

- Watchdog Timer: Automatically de-energizes all relays on control system failure .

- Short-Circuit Protection: Current-limiting circuits prevent damage during overloads .

Application Scenarios

| Domain | Use Cases | Key Capabilities Utilized |

|---|---|---|

| Industrial Automation | Machine safety interlocks, conveyor belt control, and robotic cell e-stops | 32-channel density; 250V AC switching for motor controls . |

| Power Generation | Circuit breaker control in substations, generator excitation systems | Latching relays for fail-safe state retention . |

| Manufacturing | Production line sequencing, furnace temperature control | ≤1 ms response time (solid-state) for precision timing . |

| Transportation | Rail signaling, crane control systems | Optical isolation for EMI resilience in noisy environments . |

Technical Differentiation

| Parameter | VMIVME-2200 | Typical PLC Relay Cards |

|---|---|---|

| Switching Capacity | 250V AC / 5A | ≤120V AC / 2A |

| Isolation Voltage | ≥1,500V (channel-to-bus) | ≤250V |

| Lifespan | ≥1 million cycles | ≤100,000 cycles |

| Integration | Native VMEbus control | Requires protocol converters |

Model Variants & Integration

- Suffix Examples:

VMIVME-2200-100: 16-channel electromechanical relay board .VMIVME-2200-121: 32-channel solid-state variant .

- Software Support:

- Compatible with GE Proficy® PLCs, VxWorks, and QNX real-time OS .

- APIs for C/C++, Python, and LabVIEW .

- Ecosystem:

- Direct integration with GE VMIC CPUs (e.g., VMIVME-7750) and VME64x backplanes .

Discover our other products

CP50B07030PXS00

CP50B07040D07

CP50B07040D4F

CP50B07040D50

CP50B07040D81

CP50B07040DBS00

CP50B07040DBS50

CP50B07040DS1

CP50B07040DXA02

CP50B07040DXS07