Detailed content

Technical Specifications

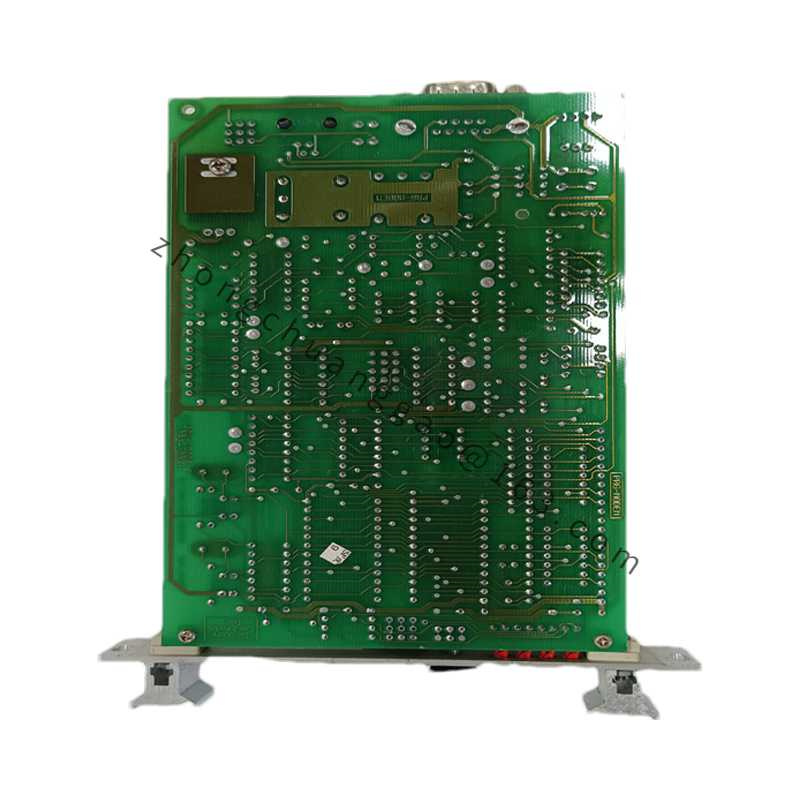

- Model: PRG-MODEM

- Type: Modem

- Functionality:

- Provides communication capabilities for GE control systems, enabling remote access and data transfer.

- Facilitates communication between control systems and remote terminals or other communication networks.

- Power Requirements:

- Voltage: Operates typically on standard industrial power supplies, such as 24V DC or 5V DC, depending on the configuration.

- Power Consumption: Power consumption details are usually provided in the technical documentation.

- Communication Specifications:

- Data Rates: Supports various data rates for efficient data transfer; specific rates should be detailed in the module’s datasheet.

- Protocols: Compatible with standard communication protocols used in industrial automation systems.

- Physical Specifications:

- Form Factor: Designed to fit into standard industrial racks or chassis, or may be a standalone unit depending on the model.

- Dimensions: Conforms to industrial standards for modems, with dimensions specified in the technical documentation.

Features

- Remote Communication:

- Enables remote communication with GE control systems, allowing for monitoring, control, and diagnostics from a distance.

- Facilitates remote access to system data and parameters.

- Data Transfer:

- Supports reliable data transfer between control systems and remote locations.

- Ensures accurate and secure communication for data exchange.

- Compatibility:

- Designed to work with GE’s industrial control systems and other compatible equipment.

- Supports various industrial communication protocols for integration.

- Reliability:

- Built for reliable operation in industrial environments.

- Includes features to handle electrical noise and other disturbances commonly found in industrial settings.

- Ease of Integration:

- Provides straightforward integration with existing control systems and networks.

- Modular design allows for easy installation and configuration.

Applications

- Industrial Automation:

- Used for remote communication and control in industrial automation systems.

- Facilitates monitoring and management of automation processes from remote locations.

- Remote Monitoring:

- Enables remote monitoring of industrial equipment and control systems.

- Supports diagnostics and troubleshooting without requiring on-site visits.

- Data Acquisition:

- Facilitates data acquisition from remote sensors and devices.

- Supports data transfer to central control systems for analysis and processing.

- Process Control:

- Applied in process control systems for remote data access and control.

- Enhances the ability to manage and monitor process variables from a distance.

- Energy Management:

- Used in energy management systems to facilitate remote communication and data exchange.

- Supports monitoring and control of energy production and distribution.