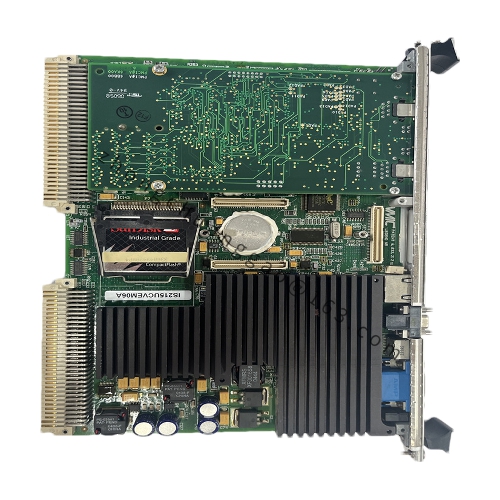

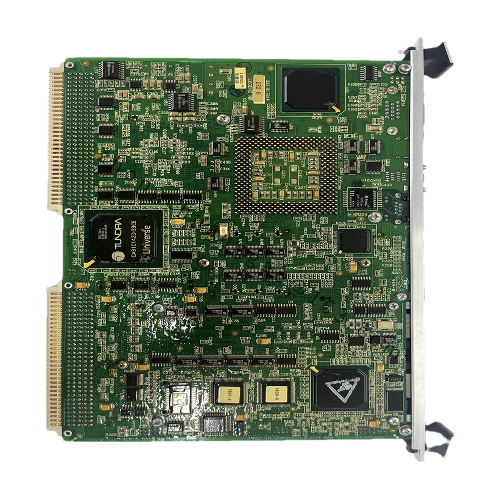

GE IS215UCVEM06A

Product Name: GE IS215UCVEM06A Analog Input Module

Manufacturer: General Electric (GE)

Technical Specifications:

Type: Analog Input Module

Input Signals: Voltage or Current signals, capable of representing various physical quantities such as temperature, pressure, and flow rate.

Channels: Multi-channel, allowing simultaneous monitoring of multiple analog input sources.

Signal Range: Configurable, allowing users to set the input signal range based on application requirements for accurate signal acquisition and measurement.

Resolution: High resolution for precise data capture.

Detailed content

Communication Interfaces: Equipped with communication interfaces such as Ethernet, Modbus, Profibus, DeviceNet, etc., enabling data exchange and integration with other automation devices, control systems, sensors, and actuators.

Power Supply: Typically 220V, ensuring stable operation.

Protection Rating: Industrial-grade design with high reliability, anti-interference, and protection features, suitable for use in industrial environments.

Operating Temperature: Designed to operate within a specified temperature range, typically suitable for a wide range of industrial applications.

Functional Features:

Signal Processing: Capable of receiving and processing analog input signals, converting them into digital data for further processing and analysis.

Configurable: Users can configure the module’s behavior through configuration software or programming to meet specific application requirements.

Data Filtering and Calibration: Some models may support data filtering and calibration functions for improved accuracy and reliability.

Real-time Performance: Able to respond to changes in input signals at millisecond levels, ensuring timely data acquisition and control.

Application Scenarios:

Industrial Automation: Used in controlling and monitoring industrial production processes, including manufacturing, assembly, and packaging.

Process Control: In industries such as chemicals, oil and gas, and pharmaceuticals, it may be used to monitor and regulate production process parameters.

Power System Control: Utilized in power systems for controlling and monitoring power generation, transmission, and distribution processes.

Equipment Control: For controlling and coordinating various industrial equipment, including motors, valves, pumps, and more.

Data Acquisition and Communication: Capable of data acquisition and communication, transmitting equipment status and data to other systems.

Safety Systems: In some applications, it may be involved in safety systems, monitoring and responding to abnormal conditions in equipment or processes.