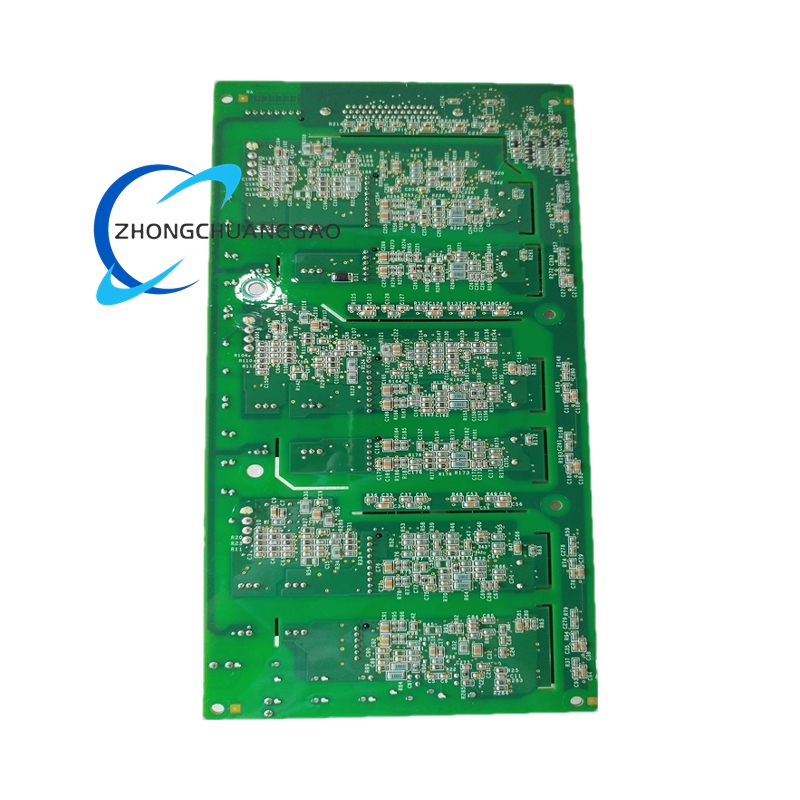

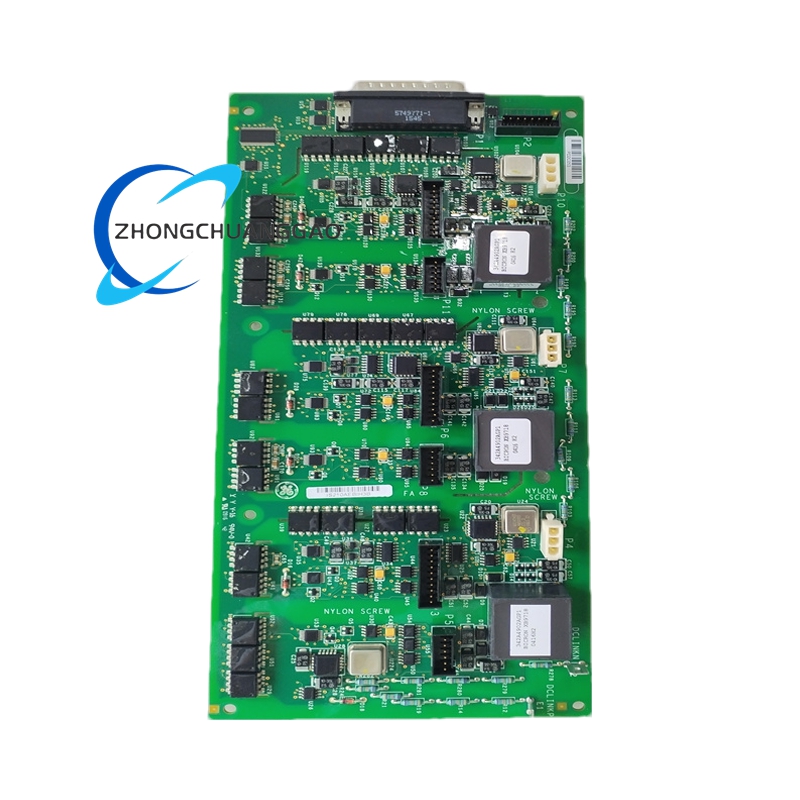

GE IS210AEBIH3B AE Bridge Interface Board

Technical Specifications

- Interface Type: Dual Ethernet ports supporting 10/100/1000 Mbps speeds

- Communication Protocols: Supports standard industrial protocols including Ethernet/IP, Modbus TCP, and GE’s proprietary Speedtronic communication protocols

- Network Redundancy: Features such as Rapid Spanning Tree Protocol (RSTP) or link redundancy to ensure network reliability and continuous operation

- Data Throughput: High bandwidth capacity to support real-time data exchange between controllers, HMIs, and diagnostic systems

- Operating Voltage: Typically powered by the backplane within the Mark VIe chassis, with nominal voltage around 3.3V and 5V DC

Detailed content

- Operating Temperature: Designed for industrial environments, typically operates from 0°C to +60°C

- Storage Temperature: Can be stored in temperatures ranging from -40°C to +85°C

- Humidity Tolerance: Functions reliably in humidity levels from 5% to 95% non-condensing

- Mounting: Designed for plug-in installation into the Mark VIe I/O or controller chassis

- Standards Compliance: Meets relevant industrial standards for electromagnetic compatibility (EMC), safety, and environmental resilience

Functional Features

- High-Speed Communication: Enables fast and reliable data transfer across the control network

- System Integration: Acts as a bridge between the Mark VIe control system and plant-wide networks, including DCS, SCADA, and asset management systems

- Redundant Network Support: Supports dual network configurations to enhance system availability and fault tolerance

- Diagnostic Capabilities: Provides detailed network status monitoring, error logging, and fault detection for proactive maintenance

- Hot-Swappable: Designed for replacement or maintenance without shutting down the entire control system

- Secure Communication: Supports network security features to protect against unauthorized access and ensure data integrity

Application Scenarios

- Power Generation: Used in gas and steam turbine control systems within thermal, combined cycle, and simple cycle power plants

- Industrial Turbomachinery: Applied in facilities using large turbines for mechanical drive applications in oil & gas, petrochemical, and manufacturing sectors

- Remote Monitoring: Facilitates connection to remote diagnostic centers for performance analysis and predictive maintenance

- Control System Upgrades: Integral in modernization projects where legacy systems are replaced or upgraded to Mark VIe platforms

- Distributed Control: Enables integration of distributed I/O and control nodes across large industrial sites