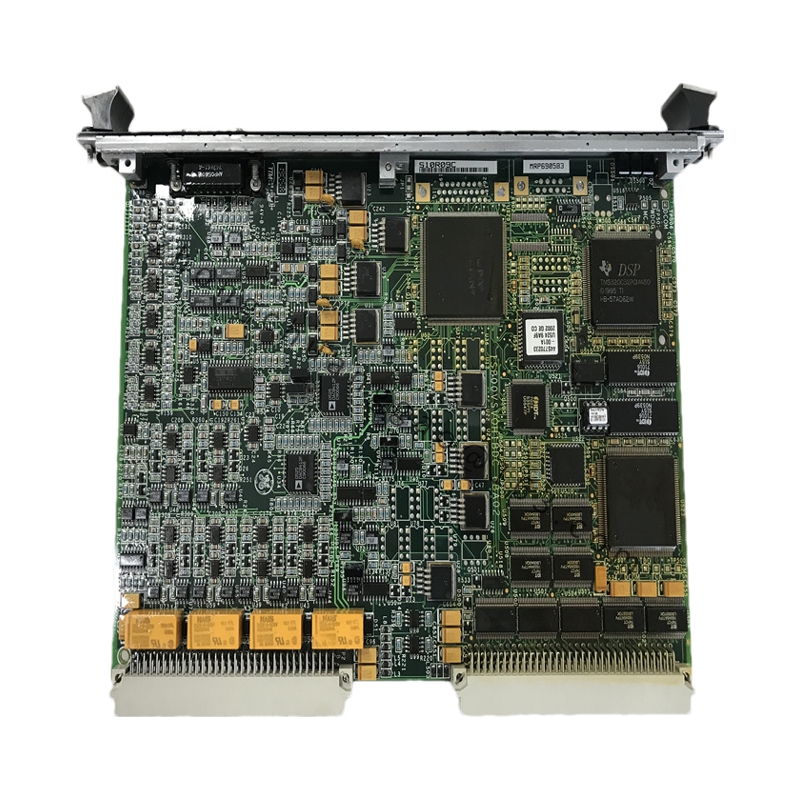

GE IS200VSVOH1B

Application Scenarios:

- Turbine Control: Primarily used in gas and steam turbine control systems, as part of GE’s Speedtronic series, which has been in operation since the 1960s.

- Industrial Automation: Widely applicable in industrial automation systems requiring high-precision motor control and energy efficiency.

- Critical Infrastructure: Suitable for use in critical infrastructure applications where reliability and redundancy are paramount, such as power generation and distribution facilities.

Detailed content

Technical Specifications:

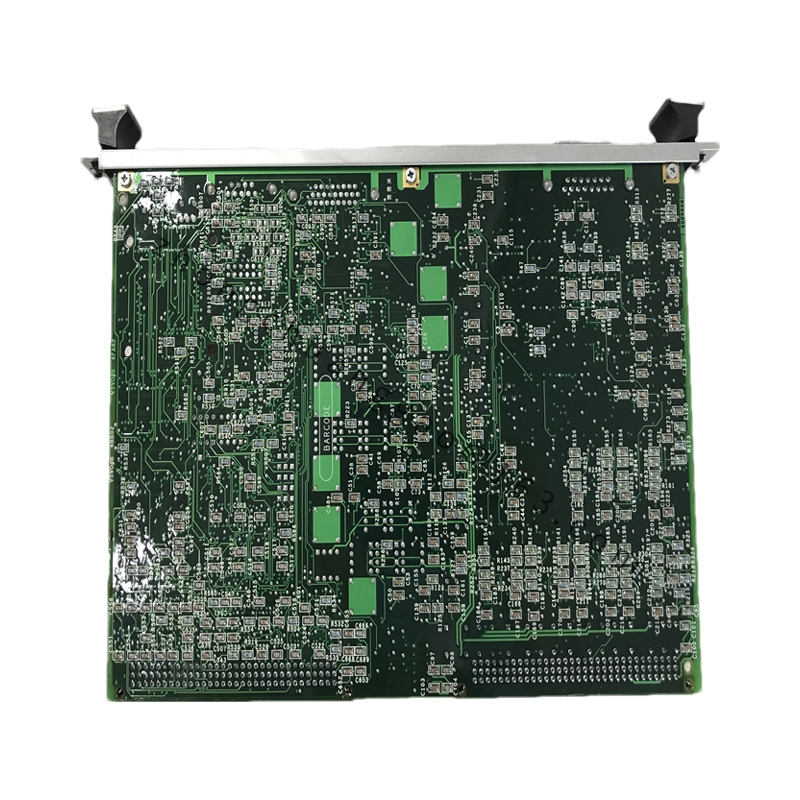

- Component Type: Circuit board assembly specifically designed for the Mark VI control system by General Electric (GE).

- Functionality: Serves as a servo control board, controlling four electro-hydraulic servo valves to drive fuel/steam valves.

- Connectivity: Includes six connectors, two backplane connectors (P1/P2), and four connectors (P3 to P6) made with conductive traces.

- Components: Equipped with four relays (K1 to K4), resistors, capacitors, TP test points, and inductance beads (L1-L10). The board also contains numerous integrated circuits.

- Indicators: A single-slot front panel connected to the PCB, featuring a cable connector (J5) and LED indicators for status information (RUN – green, FAIL – red, STATUS – orange when active).

Functional Characteristics:

- Integrated Control: Designed specifically for turbine control, integrating hardware and software tailored for this purpose.

- Communication Capabilities: Incorporates Ethernet communication functionality, enabling seamless connectivity within industrial networks.

- Redundancy Support: Compatible with both triple redundancy systems and simplex systems, ensuring high availability and reliability.

- Monitoring and Diagnostics: Provides pulse rate flow input, LVDT excitation, and LVDT position feedback for precise monitoring and control.

- High-Precision Control: Capable of achieving precise motion control through its servo valve control mechanism.