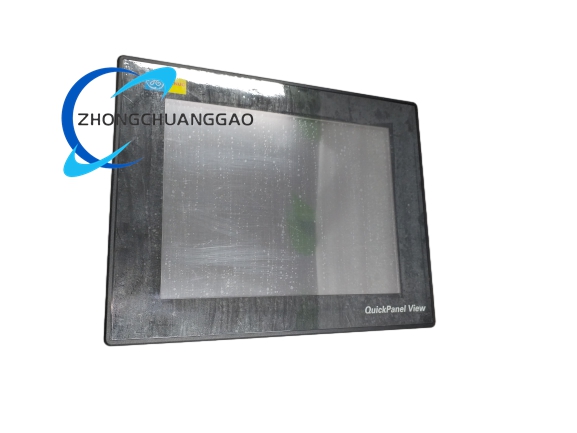

GE IC800VMA202-CB

Technical Specifications

- Processor: High-performance CPU optimized for real-time motion control tasks.

- Memory: Built-in storage for program execution and data logging (exact capacity varies by configuration).

- Communication Interfaces:

- EtherNet/IP, Profinet, Modbus TCP: Enables seamless integration with other industrial devices and systems.

- Optional serial ports (RS-232/RS-485) for legacy equipment connectivity.

- I/O Expansion: Supports digital/analog inputs/outputs and dedicated motion control signals (e.g., pulse trains, encoder feedback).

- Power Requirements: 24VDC ±10%, with low power consumption for energy efficiency.

Detailed content

- Operating Conditions:

- Temperature: -20°C to +60°C (operating), -30°C to +70°C (storage).

- Humidity: 85% RH (non-condensing).

- Enclosure Rating: IP65 (front panel) for dust and water resistance.

- Certifications: CE, UL, and other industry-specific approvals for global deployment.

Key Functional Characteristics

- High-Speed Motion Control: Handles complex trajectory planning and execution with sub-millisecond latency, ensuring precise positioning and synchronization.

- Multi-Axis Coordination: Supports synchronized control of multiple servo axes for applications like robotic arms or CNC machines.

- Flexible I/O Configuration: Modular design allows customization of digital/analog inputs/outputs to match application requirements.

- Safety Features: Built-in safety mechanisms for emergency stop, fault diagnosis, and risk mitigation in hazardous scenarios.

- Programming Flexibility: Compatible with Proficy View Machine Edition and other tools, supporting ladder logic, structured text, and motion control-specific languages.

- Data Handling: Logs real-time performance data (e.g., position, velocity, torque) for troubleshooting and process optimization.

- Redundancy Support: Optional redundant configurations for enhanced system availability.

Application Scenarios

- Robotics: Controls robotic arms, grippers, and end-effectors with high precision and repeatability.

- Packaging Machinery: Automates filling, sealing, and labeling processes with synchronized motion control.

- Material Handling: Manages conveyor systems, pick-and-place robots, and palletizers for efficient logistics.

- CNC Machining: Drives spindles and servo axes in milling, lathe, and laser-cutting machines.

- Printing and Converting: Synchronizes print cylinders, tension control, and registration systems in high-speed presses.

Advantages

- Scalability: Modular architecture supports future upgrades without replacing the entire system.

- Reliability: Designed for 24/7 operation in extreme conditions with minimal downtime.

- Interoperability: Works with third-party devices via open protocols like EtherNet/IP and Modbus TCP.

- Legacy Compatibility: Integrates with older GE automation systems for cost-effective retrofits.

- Energy Efficiency: Optimized power consumption reduces operational costs in continuous-duty applications.